The Riskiest Mining Jobs In The World | Risky Business Marathon | Insider News

2.51M views6079 WordsCopy TextShare

Insider News

These are the stories of the people working in the mining industry. We explore how sulfur, coal, lim...

Video Transcript:

Narrator: Every day, we use products that are mined, often under dangerous conditions. In Indonesia, workers pull out sulfur from an active volcano while inhaling toxic gases. Deep in the coal belt of India, 17-year-old Rinky illegally mines and carries coal that weighs as much as her.

And here in Egypt, limestone that's used to make cement is causing respiratory diseases. We got an inside look at mines across the world to see how workers risk their lives to make ours better. Our first stop are the limestone quarries in Egypt, where miners work with sharp blades under the brutal sun, all for a wage of $6 a day.

Narrator: About 160 miles south of Cairo sits one of the largest limestone deposits in the world. This is Al Minya, Egypt, and hundreds of mines dot the landscape. Tens of thousands of freelance miners chip away at this land.

For these guys, each day starts in Minya City at dawn. And this is where the danger begins. These trucks aren't meant for passengers.

Workers have gotten injured from falls along the winding journey. Narrator: The trip to the mountain takes about 40 minutes. Narrator: The workers first share a meal while the sun rises.

Then it's time to get suited up. Since these miners are freelancers, they have to buy their own protective gear. Often, homemade cloth masks, gloves, and sunglasses are all miners have to shield them.

They grab their tools and descend into the pit. The most important one is the round saw, and that's also the most dangerous. First, miners have to set up these two rails.

Two separate machines roll along the tracks. They slice the stone into perfect cuboids beneath. Narrator: The machines move quickly.

They're really heavy, and they're loud. Narrator: Workers shout at each other to warn the machines are nearby, because the real hazard is those saws. A quick step is all that separates miners from razor-sharp blades.

Narrator: Miners are responsible for fixing the machines when they break and sharpening the blades by hand. That's also risky work. Narrator: The cutting machines used to have covers, but they fell off years ago.

Now the blades are exposed. Narrator: While the mine owner says he makes sure the electrical wires are covered, many are unprotected. Narrator: As the machines cut stone, they kick up rocks in a haunting white cloud of limestone powder.

If there's no wind, miners disappear in it like ghosts. It's easy to inhale the fine dust, and if they breathe it long enough, it can cause a long condition called silicosis. Narrator: Injuries, sickness, and death in these mines are widely reported, but there aren't any official numbers.

At one point, the life expectancy here was just 45 years old. Narrator: Zaki says many mine owners will offer under $200 by way of workers' comp. Narrator: Once the stone is safely cut, workers turn the blocks so the machine doesn't break them as it goes by again.

At the start of a new quarry, the stones don't come out perfect. Those chunks head to a separate factory to be ground into powder. Perfectly cut stones that haven't been sold yet get stacked, but these blocks have already been purchased, so miners throw them straight into the truck.

And they have perfect aim. If they're lucky, they might get a $3 stipend for food and tea on top of their $6 daily wage. Narrator: The bricks are sent to Cairo, which has around 80% of Egypt's limestone-processing capacity.

The limestone is made into cement and tiles and used in papermaking, plastic production, agricultural products, and even medicine. Globally, the limestone market hit an estimated $73 billion in 2020. Today, Egypt is the largest exporter of limestone in Africa, producing more than 150,000 metric tons.

The stone is so lucrative that Minya's economy depends on it. That's why many miners do this work. Their $6 wage is more than they'll make farming or working in construction.

Narrator: And more people, from students to farmers, flock to the mines when unemployment spikes. Narrator: But human exploitation for mining limestone in this area is not new. In fact, its history is ancient.

Through the years, Egyptians used the stone in pyramids, temples, and tombs. Dark limestone made up the core of the Great Pyramids of Giza, and blinding white limestone once covered the outside, symbolizing purity and sacredness. Then, in 1303, an earthquake loosened the outer stones of the Great Pyramid.

The white layer was stripped off to be used in the construction of mosques. Today, by one estimate, more than half the limestone quarries in Minya are unlicensed. The government has cracked down on some, closing 400 by 2019 after reports of injuries, but many illegal mines are still operating with deadly conditions and no oversight.

So workers have had to take matters into their own hands. They negotiated a pay raise and created a fund for injured workers and their families. But they faced pushback from mine owners.

Narrator: The mine we filmed is licensed. It's called Uncle Waleed's. But the owner told Business Insider the miners still have to provide their own gear.

Narrator: At the end of his shift, Atef relaxes with a cup of tea and a meal with his friends. The eerily beautiful mine stretches in front of them. It's a beauty they hope will get the world's attention, enough to send some help.

Narrator: Himalayan salt doesn't actually come from the Himalayas. It's mined 186 miles away in Pakistan. Thanks to its pink hue and supposed health benefits, the salt has exploded in popularity since the late 2000s.

Today, it's turned into lamps, statues, and of course, table salt. But extracting the coveted salt means descending into dark caves, then blasting and carrying heavy rock. Narrator: We went inside the mine turning this mountain into 400,000 tons of pink salt each year.

The Khewra Salt Mine here in the Punjab region of Pakistan is the second-largest salt mine in the world. The pink salt comes from remnants of ancient seabeds that crystallized 600 million years ago. Legend has it, it was actually Alexander the Great's horse that first discovered these salt rocks when it stopped to take a lick.

Then, under British rule, salt mining ramped up in the 1870s. Today, it's a popular tourist destination and a working mine, producing the majority of the world's pink salt. All the mining starts here, at the train station.

This train takes miners deep into the mountain. Here, tunnels stretch for 25 miles, and it's always 64 degrees Fahrenheit. Narrator: Three hundred miners work these dark chambers.

They've used many of the same mining tools for over a century: pickaxes, hand drills, and gunpowder. Narrator: Miners will spend up to eight hours underground at a time. Narrator: Only half of the mountain salt is actually mined.

The rest is used for structural support so the chambers don't collapse. Tractors haul the mined salt out of the mountain. Each day, miners excavate over 1,000 tons of salt, or about the weight of 157 elephants.

Outside, they search for blocks with the best shape and coloring to send to manufacturers. Once picked, the blocks are loaded up on trucks either by hand or crane and sent across Pakistan. Historically, Pakistan couldn't process this raw pink salt, so much of it was exported to India cheaply.

India would treat the salt, label it as made in India, and sell it at a premium. Pakistan saw little of the profits. NPR reported that a ton of salt sold to India for $40 could fetch $300 in Europe.

In 2019, a social media campaign calling for the end of salt exports to India went viral. That same year, the Pakistani government banned all salt exports to India. The goal?

Returning the profits to Pakistan. Narrator: But some Pakistani salt exporters suffered. They didn't speak English and couldn't meet Europe's tough import standards.

Only about a dozen exporters saw an opportunity to sell products under Pakistani labels directly to Europe. Muhammad was one of them. Every month, he purchases 300 tons of salt from the mine for his company, Himalayan Decor International.

Narrator: His artists turn these blocks into more than 200 different products. Narrator: Most of the work is done by hand, but drills and saws have sped up the process in recent years. Narrator: Over in Karachi, RM Salt Pakistan grinds up blocks into table salt.

Narrator: Blocks are fed into the grinder and broken down into smaller grains. Workers bag and weigh 1,000 of these pouches of pink salt every hour. Like Muhammad's factory, RM Salt also makes lamps and other specialty products.

After the raw material we get, we convert it with a different shape as per our order. Like you can see in the cutting machine, he's cutting different sizes. Narrator: On this saw, water prevents dust from flying up.

But on the grinders, it's not possible, which is why Muhammad's staff wore masks even before the pandemic. Over at RM Salt . .

. Narrator: The lamps are then coated with the gel to prevent humidity from interacting with the salt, and then they're shrink-wrapped. RM Salt ships 30 containers of products every month.

Muhammad exports about 80% of his products primarily to Western countries like the US, UK, and Spain, where demand has spiked in the last decade because of the alleged health benefits. However, it's such a very small percentage of the salt makes up these minerals that you are highly unlikely to get any real benefit, or any trace of them, in your regular serving of salt itself. But nutritionally, it's pretty much similar to regular salt.

Narrator: It's also pretty similar-tasting to sea salt. But others claim Himalayan salt has healing powers, whether inhaled, used in spa treatments, or in lamp form. There's a lot of different homeopathic remedies that can seem very, very appealing, but actually they're not grounded in evidence.

Narrator: And it's these false health claims that have driven the price up. Himalayan salt can cost up to 20 times the price of normal table salt. Narrator: But that money doesn't always make it back to the miners.

They take home less than 1,500 rupees a day, not much more than the cost of this bag of Himalayan sea salt at Walmart. And those salaries have stayed the same, even though Pakistan has severed its salty relationship with India. And the pink salt is seeing growing demand abroad.

Narrator: Luckily, the mountain won't run out of salt anytime soon. It's estimated only about 220 million tons of salt have been excavated here. Nothing compared to the nearly 6.

7 billion tons left. Narrator: India is one of the world's largest producers of salt, and a third of it comes from deep in this desert. The dry, cracked land of Little Rann of Kutch was once a seabed.

Today, over 6,000 families live in this desert farming salt by hand. They're known as the Agariyas, and they've been salt producers in this harsh environment for generations. Narrator: The air can reach up to 118 degrees Fahrenheit.

And the land they work on is so salty . . .

Narrator: All to earn just $4 a ton. That same salt will sell for $260 a ton as table salt, soap, or detergent. Narrator: The Agariyas have faced a long history of mistreatment.

But that stigma continues, and this is why the salt farmers still continue to do this job. Narrator: There have been government efforts to change things in recent years, but many still live in poverty. We went to India to learn how the Agariyas became trapped in the big business of salt.

Thousands of years ago, this area was part of the Arabian Sea. Narrator: It was still waterlogged, though, as part of the Indus River Delta, but an earthquake in 1819 changed the direction of the river. Bhavna: And therefore, this entire area got dried up.

Narrator: But the water that still sits underneath the mud is 10 times more saline than seawater, making it a perfect place to farm salt. Bhavna: It was considered as a commodity, which is equivalent to gold. Narrator: And the Agariyas have been working here ever since.

Monsoons fill this area with water starting in June. It can take another four months for the waters to recede. That is when the salt farmers come into the picture.

Narrator: Bhavna Harchandani is a research scholar who lived with the salt farmers for seven months. The Agariyas arrive every year in October. Patadiya Ghughabhai and his wife carry everything they'll need to live in the desert for the next six months, including supplies to make their huts, clothes, farming tools, and all their food and water.

Narrator: First, they have to find the key to this whole operation, salty brine water underground. They dig 30 feet into the mud to get to it. Digging wells can take up to a week.

The families then set up these government-subsidized solar panels. They'll power the pumps that bring brine water to the surface. Then the Agariyas build the salt pans, these expansive salt flats.

Narrator: The roller helps them flatten out the earth. Narrator: They'll make 10 to 20 pans all by hand. It's back-breaking work.

Bhavna: Now working in the desert is not a joke. Narrator: Everyone in the family pitches in to help. Narrator: Then the farmers will release the salty brine water from the wells.

It flows between the pans. By the last pan, the water reaches the 24% salinity needed to form big salt crystals. The farmers are so skilled that they know it's the perfect salinity simply by tasting the water.

Narrator: Over the next few months, as the water evaporates, salt crystals form. Narrator: This rake costs $22, too expensive for many of the farmers. Narrator: They have to rake the salt crystals every day for the first three months.

Narrator: They start raking early each morning to avoid the hottest part of the day. Narrator: But working here can be really dangerous. The life expectancy of a farmer is about 60 years, because not only do they face extreme temperatures .

. . They're dealing with subsoil brine, which is highly acidic, and an exposure to that subsoil brine also comes with a lot of problems in skin.

Narrator: Many of the Agariyas become blind from years of the bright sun reflecting off the white landscape. And because they're so far from the nearest village, accessing medical care is often too expensive. Narrator: Despite these conditions, the Agariyas live and work out here until spring, when the salt is finally ready.

They harvest three times. The first produces the best-quality salt. They leave in April, usually with over 1,000 tons of salt, and they'll sell it to a trader like Rafiq Rahimbhai.

Narrator: His team picks up the harvest with trucks. Once it arrives from the Rann . .

. Narrator: Rafiq employs 200 workers at his factory in Tikar processing and packaging salt. He says he loses about 20% of the salt during the washing and draining process.

Narrator: It gets packaged and sold as edible powder salt and as crystal salt to be made into soap, detergent, and baking soda. This whole process refines the salt and makes it more valuable, so Rafiq can sell his product for upwards of 60 times what the farmers make. Bhavna says in the time she lived there, she saw salt traders working together to pay as little as possible.

Bhavna: If I'm a farmer, if I go and argue that this price is too low, I need more, he will say, "OK, don't give your produce. Go to someone else. " And then that man, the trader, will go and tell the other trader, "If this man comes to you, don't take his produce.

" Narrator: Rafiq denied taking part in such practices and says farmers can negotiate their prices. Narrator: Rafiq says he pays the farmers above average, between $5 and $8 a ton, but Insider could not confirm that. And most farmers we spoke to said that this season's market price for salt is between $2 and $4 per ton.

Narrator: That means in a good year, a family will earn just over $4,000 for six months of grueling work. But this doesn't pay for all the expenses they have as they prepare for the next harvest. So at the start of each season, many Agariyas have to come back to traders like Rafiq and ask for a loan to help them get through it.

However, that taking advance has now made them fall into the vicious trap of loans and debts. This is the reason why they are unable to come out. Narrator: That means in a good year, a family will earn about $2,000 for months of grueling work.

That's well below the poverty line. The Agariyas have never really had control over the salt they farm. The British classified the group under the Criminal Tribes Act of 1871, basically branding all members as criminals from birth.

But many historians say it was really a way to control tribes that were poor, low-caste, or didn't support colonial rule. The law gave police the power to monitor the Agariyas' movements and arrest them with little cause. The British also owned this land, so even though the farmers were still allowed to work here, the British would take the salt to England, process it, and sell it back to Indians with a heavy tax.

Bhavna: The salt farmers, they were not supposed to take their salt out from the region. So what the women used to do, they used to hide the salt crystals in their petticoat, and then they would take it out, because salt was expensive. Narrator: Many Indians couldn't afford the taxed salt, even though it was a staple in their diet.

Bhavna: If you cut off the salt supply, it's like, you know, you are waging a war. Narrator: It got so bad that in 1930, Mahatma Gandhi organized one of his most successful acts of civil disobedience, a 240-mile salt march. TV announcer: As he moved from town to town, it seemed that all of India was behind him.

Narrator: 60,000 protestors were jailed, including Gandhi himself. Salt would be contested until India's independence in 1947. After British rule, the Agariyas were denotified, meaning they were no longer classified as a criminal tribe.

Bhavna: But that stigma continues. Narrator: With few other options, they were trapped producing salt. Bhavna: This is why the salt farmers still continue to do this job.

Narrator: And they're still working on land they don't own. After the British left, the Little Rann of Kutch was taken over by the government, which leased it to the Agariyas. Bhavna: However, the government has stopped renewing their lease.

Narrator: And in 1972, most of the area became a protected wildlife sanctuary. Bhavna: Therefore, they are illegally producing salt. They're considered as illegal.

Narrator: But the government has an unspoken agreement with the community, allowing them to keep farming around the protected areas. The government even provides equipment, like the subsidized solar panels and boots to help protect against foot infections. Narrator: In the long term, the salt farmers and their advocates hope for more government involvement, starting with setting a minimum price for salt.

Narrator: Ecologist Ajay fears that might backfire. Narrator: As their own farming depletes the brine, the Agariyas are moving deeper into the desert, further away from established towns and villages. Bhavna: Probably we can at least provide them with minimum water facility so that at least they have some amenities.

Narrator: But until help arrives, these people will be back next season. Narrator: Rinky Kamari has been working at India's largest coalfield since she was only 8 years old. Narrator: It's technically illegal for her to be here.

Narrator: But she risks her life every day to help feed her family. She inhales toxic smoke and often burns her hands and feet. Narrator: But at 17, she still endures these brutal conditions with a smile.

Narrator: We followed this young woman to see why people here keep working in such a risky business generation after generation. Narrator: Rinky and her mom stop and pray to Kali, the goddess of death, on their way to the Jharia coalfield. Coal collectors built the shrine to honor people who died here.

Most of the official mines are operated by a subsidiary of government-owned Coal India called Bharat Coking Coal Limited, or BCCL. People like Rinky dodge police to sneak in and scavenge. Narrator: The best time to avoid getting caught is from 4 to 10 in the morning.

Any later in the day, it gets feverishly hot. Narrator: Rinky has been injured a few times. Narrator: She lost a friend in the mines a few years ago.

Narrator: Rinky's friend, Lakshmi, is just 12 years old. And she often collects the same amount of coal as an adult. Rinky's basket weighs as much as she does, around 90 pounds.

Narrator: Rinky walks about eight miles a day, making several trips from the mine to her home to drop off the coal. Narrator: When she gets home, she cooks the coal to make it usable as fuel. Narrator: Rinky makes about 800 to 900 rupees a week selling coal in the market to locals and restaurants.

In India, that's about $11, roughly the cost of a pair of sneakers. But the risks don't end when she leaves the mines. And the same thing that helps Rinky support her family is also making them sick.

Coal deposits contaminate nearby rivers and streams, especially during monsoon season. Narrator: Nearby hospitals like this one are overflowing with patients who work in the mines. Dr Ramesh Kumar Sharma sees about 150 patients a day.

Narrator: Jharia's air quality is one of the worst in the world. The coal underground has been burning for more than 100 years. Experts say it catches fire on its own when exposed to oxygen.

Flammable gases like methane and carbon monoxide seep through homes. Narrator: The floor in her house is always hot. Narrator: The mining company frequently explodes dynamite to expose the coal.

That's destabilized the entire neighborhood of Jharia, creating cracks in the earth and swallowing up homes. Narrator: Rinky's house made of concrete blocks is slowly sinking. Narrator: Rinky's father remembers what life was like in Jharia when they moved here in 2005.

Narrator: Now the fires have spread so much that BCCL is moving thousands of families out of Jharia. But the process has been slow. Many locals say they don't want to move far away from the mines where they work.

Others are mistrustful of BCCL's motives. Narrator: Insider reached out to BCCL for comment but did not hear back. Coal consumption is on the decline in many countries, but not here.

India is the second-largest consumer in the world. Coal fuels 70% of the electricity grid. And with a nationwide energy shortage unfolding, the government is doubling down.

It plans to reopen 100 old mines this year. Narrator: But Rinky doesn't want to be here forever. Four years ago, she got an opportunity that could change her life.

Narrator: She joined the Coalfield Children Classes, run by an NGO. About 100 kids are enrolled here. Narrator: And she has big dreams.

Narrator: Even though she's still figuring out her next step, Rinky tries to find bright spots in the risky job she must keep doing for now. Narrator: Hundreds of miners work inside an active volcano here in Indonesia, battling toxic fumes all day long. They're mining sulfur, which locals call "devil's gold.

" Working conditions here are so dangerous, many miners don't live past 50 years old. Narrator: Miners like Mistar carry up to 200 pounds of sulfur on their backs up and down these steep cliffs. And Mistar has been doing it for 30 years.

Narrator: The sulfur is used in everything for matches and rubber to cosmetic products. It's even what makes our sugar white. Narrator: But most of the world's sulfur comes from oil and gas refining, making volcanic mines like this relatively obsolete.

Yet these miners are still working, earning about $12 to $17 a day. Because in this remote part of Indonesia, it's one of the better-paying jobs. Narrator: So why is this form of sulfur mining still happening?

And what makes it such a risky business? Narrator: This is as far as Mistar can go on his bike. There are no roads to the crater, so he has to walk the rest of the way.

It's a 2-mile hike up to the ridge of Ijen volcano. Narrator: He takes only his basket and a crowbar down into the 1,000-foot-deep crater. Here, he faces the volcano's extreme environment.

The air can reach over 100 degrees Fahrenheit, and he works near one of the world's most toxic volcano lakes. Narrator: And there's the smoke. Narrator: He battles two types of sulfur smoke.

The first comes from deep inside the volcano and is channeled through these pipes. Narrator: While mining company PT Candi Ngrimbi owns a license to run the mine, the miners are freelance contractors, so they have to pay for their own gear. And many can't afford gas masks.

Instead, they use handkerchiefs or towels dipped in water to keep the sulfur powder from sticking. The second type of smoke is even more dangerous. It comes from the volcanic gases below the acidic lake, and it can be deadly.

So if miners see big clouds of thin, white smoke coming from the lake, they have to evacuate. Narrator: That's why Mistar needs to get here so early. The winds pick up through the day, pulling more white smoke towards the miners.

Both types of smoke have lasting health effects. Narrator: But the smoke from inside the volcano is crucial for sulfur production. This is how it works.

When the superhot smoke hits the cooler air outside, it condenses liquid and drips off the pipe. Narrator: As it solidifies and cools, the sulfur will turn yellow, and miners can begin chipping off blocks. It's the sulfur's two colors that give it the name devil's gold.

Miners use their bare hands to move these blocks. Although touching solid sulfur frequently can cause rashes and blisters, Mistar says that as long as it's cool and yellow, a sulfur's fine to touch. Narrator: Pre-pandemic, the miners could extract up to 25 tons daily.

But since 2020, they've been working in two separate shifts to socially distance. That's lowered the miner's capacity to only 10 tons of sulfur a day. Once he fills his baskets, Mistar hoists them up on his shoulder to hike back.

But that sulfur is not a light load. Narrator: That's about 154 pounds. Mistar himself weighs just 132.

Narrator: Some of the younger miners can carry up to 200 pounds in one load. Narrator: They have to haul it up the steep walls of the crater. Narrator: Some do the treacherous hike in flip-flops.

Narrator: Once he reaches the rim of the crater, Mistar can transfer the sulfur to his trolley and begin the 2 miles back. And he'll do this trip a second time today. Narrator: PT Candi Ngrimbi, the mining company, also owns this weighing station and the factory where the sulfur ends up.

At the factory, workers boil the sulfur and run it through a series of filters. They have to remove any contaminants like sand or dirt. Then they pour it out onto the factory floor to cool.

The sulfur is loaded into sacks and sent to sugar factories nearby. It's processed into sulfuric acid, the world's most commonly used chemical. It's used in everything from matches, fireworks, and gunpowder to detergent, paper, and batteries.

It's what makes sugar white, and it's an essential ingredient in rubber products and even winemaking. But 98% of the world's sulfur comes from oil and gas refining. It's a by-product of refining, and oil companies are required by law to process it safely.

What's created is a lot of pure sulfur, a purity that's necessary for making products like fertilizer. Today, the sulfur industry from oil and gas is worth almost $13 billion and is expected to keep growing. And it's left natural mines and volcanoes unnecessary, especially since mined sulfur isn't as pure.

It can be acidic or contain sand. Yet Ijen is one of the only places left in the world where people still mine sulfur this way. So why do they do it despite the danger?

For the mining company, it's easier and cheaper to get sulfur from Ijen. For the sulfur miners, the pay is a lot more than other jobs on the island, such as farming. Narrator: The mining company pays on the weight of their loads.

They get about 9 cents per kilo. With two loads, Mistar can make $17 a day. The mining company did not respond to our request for comment on why the miners are paid so little for what's considered one of the most dangerous jobs in the world.

Another possible reason this mine is still open? Tourism. At night, visitors flock here to see the blue flame from the sulfur gas.

During the day, tourists hike up to take in the vistas. Protected with their gas masks, they watch miners work without masks of their own. Some miners are now becoming tour guides or making sulfur souvenirs.

But most keep working as they always have. Narrator: At the end of the day, Mistar returns home to eat dinner with his family and rest. Ijen looms over them, a symbol of how Mistar provides for his family's lives while it slowly takes his, a heavy weight to carry on his shoulders.

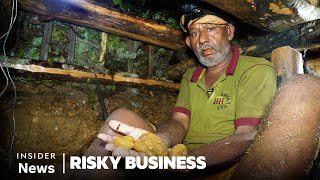

Narrator: This floating mine is home to one of the most dangerous jobs in Indonesia. Every day, Joko Tingkir risks his life to harvest a precious source from below the ocean floor: tin. Narrator: He breathes through this narrow tube powered by a small diesel engine.

Narrator: This is the best-paying job in his village. Indonesia is the world's biggest exporter of tin, but most of it has been mined on land here on the islands of Bangka and Belitung. But the tin deposits on land are almost gone, and the process of excavating it has left behind these huge, toxic lakes filled with poisonous minerals and acids.

Meanwhile, mining operations have moved offshore, and unlicensed miners scavenge the sea floor for whatever gets left behind. We followed Joko to see how he dives 65 feet underwater to collect tin and to find out what makes this such a risky business. Joko was born and raised in Bangka.

Narrator: About 40% of islanders here now work in the mining industry, and Joko knows it's the best way to feed his family. The pontoons form what looks like a small floating village, but each float has its own mobile crew. Today, the water is choppy, and there are no life vests on board.

All he has are these goggles and a basic snorkeling cap. Even just reaching the seabed is a challenge. Joko stays here for up to four hours a dive.

His oxygen supply comes from an air compressor aboard the pontoon. Sometimes, it can overheat and emit toxic gases into his air supply. Narrator: Joko pulls this blue pipe along with him on the seafloor.

First, he checks the sand for tin. But he has to be careful. Tin weighs more than sand, so Joko says he can tell there's tin mixed in based on how heavy this handful feels.

He sends a sample up to the pontoon through this blue tube so his crew can check for it, too. When his colleagues see it, they send a signal down to Joko by bending his oxygen tube, momentarily cutting off his air supply. Once he knows he's found tin, his job is to keep holding the vacuum pipe firmly in that spot.

Above, the filtration begins. His crew places these mats on the floor of the raft to separate the tin from the sand. Since tin is heavier, it falls through these pores.

The sand gets dumped back into the ocean off the back of the pontoon. Next, workers peel the mats off and bring them to these basins, where they wash out the tin that's trapped inside the pores. Then they drain the water and scoop the ore into bowls.

The whole process is loud, and it can be hard to keep tabs on Joko, who's still submerged about 60 feet beneath them. Meanwhile, sucking action from the pipe is creating a crater in the seafloor. The deeper the hole, the higher the walls of sand, and sometimes they crumble.

Joko says they've even buried his friend. Narrator: Joko worries for his life, too. At the bottom of the sea, the pressure is more than two times what it is on the ground, and surfacing too fast has damaged Joko's hearing.

Since safety is so expensive, sometimes accidents happen. Between 2017 and 2020, an Indonesian NGO recorded 40 deaths linked to tin mining in Indonesia, but many go unreported. That's because these miners are unlicensed, which means what they're doing here is illegal.

Local police go after them, but miners say they are mostly looking for bribes. Ninety percent of the country's tin-mining territory is controlled by PT Tema, a state-owned company. The government also grants licenses to small, independent crews who work on pontoons.

Getting those permits, though, means having a modern vacuum system that attaches to the seabed on its own and doesn't require miners like Joko to dive to the bottom of the sea. But pontoons like that cost six times more than what Joko works on. Tin mining in Bangka began in the 17th century.

Hundreds of years of digging has created moonlike craters on this once tropical landscape. The exposed rocks contains sulfides that react with air and water and leak acids into Bangka's waterways. Massive toxic leaks like these are everywhere.

Now, 16,000 tons of tin are left on land, but PT Tema estimates that about 265,000 tons are still in the ocean. So miners have moved to the sea. Narrator: But offshore mining is killing fish in these waters.

A local NGO found that mining at sea has damaged about 13,000 acres of reef around the island. Locals say that eight years ago, they could fish within a 4-mile radius of the island. Now, they have to travel at least 17 miles to catch enough fish to make a living.

PT Tema did not respond to our requests for comment. The four men work on the pontoon for 11 hours, taking just a short break for lunch. At the end of the day, they divide the tin among themselves.

Joko takes the most, because his job is the riskiest, but he still makes only $13 a day. That's why he can't afford the protective gear most deep-sea divers use, like a pressurized helmet that costs around $2,000. He sells his tin on the black market to middlemen like Nasrin .

. . Narrator: .

. . who buys it for 10% below the standard rate.

Narrator: So Nasrin has to refine the tin. A worker washes it again to get rid of any residual sand. Now this is the tin Nasrin can actually sell.

Workers then heat these metal platforms over an open fire. Then they pour the tin onto this blazing hot surface to evaporate any residual water. When workers inhale these fumes, particles of tin can enter their lungs and, over time, affect their breathing.

Once the tin is dried, workers gather it up into sacks. And then it's sold to smelters, who extract the metal from its ore. Tin is used in everything: phones, food cans, cosmetics, paints, and even fuel.

But recently, Joko has been struggling to get a good price, because government regulations have made it harder to find buyers for his product, which is considered illegal. Narrator: Today, Joko says he makes barely enough to feed his wife and four children. Narrator: But he says they're enough to make him conquer any fear.

And his reason to get up the next day to do it all again.

Related Videos

49:34

How People Risk Their Lives Hunting For Ge...

Insider News

4,508,602 views

43:44

Modern Marvels: How Copper Built the World...

HISTORY

2,453,149 views

49:24

Ice Diamonds: Inside Canada’s Ethical Diam...

SLICE Travel

201,014 views

2:17:02

Why 12 Of The World's Priciest Items Are S...

Business Insider

697,008 views

51:51

Rare Earth Mining: The Key to our Technolo...

Free Documentary - Engineering

209,678 views

1:16:43

How 9 Billion Phones Are Powered By Rare M...

Business Insider

1,141,151 views

1:37:44

11 Of The Most Expensive Items Made In The...

Business Insider

3,144,620 views

40:52

Toughest Jobs in the World: Cleaning Indus...

Free Documentary

1,665,440 views

51:59

Camp Century - The Hidden City Beneath Gre...

Get.factual

2,669,341 views

1:04:55

The Dangers Behind 6 Popular Foods | Risky...

Insider News

1,729,272 views

50:07

Salt, Tears of the Earth - Go Wild

Go Wild

558,616 views

48:11

MAKING MONEY: Recycling – Turning waste in...

WELT Documentary

3,013,877 views

29:23

Exposing The Inhumane Conditions Of Burkin...

Journeyman Pictures

5,359,297 views

2:19:38

12 Deep Sea Jobs Around the World | Busine...

Business Insider

167,915 views

42:17

The Congolese Tribes Selling Weed to Survi...

VICE

8,252,209 views

1:58:27

12 Jobs That Take A Lifetime To Master | S...

Business Insider

12,988,784 views

33:51

The True Cost Of Mining Electric Car Batte...

Insider News

1,390,406 views

52:24

The Diamond's Business

Best Documentary

2,804,022 views

49:55

World's Most Dangerous Jobs: Lumberjacks |...

Free Documentary

121,080 views

53:25

The Deepwater Horizon Oil Spill in the Gul...

FRONTLINE PBS | Official

1,567,123 views