A Diferença entre MOTORES e GERADORES elétricos. Motores vs Geradores - O Que Você Precisa Saber!

64.71k views1444 WordsCopy TextShare

Engenharia Detalhada

❗❗❗ Seja membro deste canal e ganhe benefícios:

https://www.youtube.com/channel/UCAaD-P-PxAkKS5WX8Ep...

Video Transcript:

What is the difference between a generator and an engine? Hey Engineering Lovers, we recently posted a short that showed what it was like inside a wind turbine and several comments surprised us. Several people asked if it was a motor, others saying it was a generator.

And other comments asking us to clarify the difference between engines and generators. But before we move on to this topic, take the opportunity now to subscribe if you are not already subscribed, leave your like, and activate the notification bell and if you find our content interesting, consider becoming a member to help us continue producing content here on the platform and be remembered in our videos. And check out the pinned comment and we've put together a list of courses we recommend.

So come on, what is the difference between a motor and a generator? In short, it's very simple, a generator converts mechanical energy into electrical energy and a motor converts electrical energy into mechanical energy, but let's explore a little more. A generator, in other words, generates electricity from some type of mechanical movement.

Imagine the generator as a machine that generates electrical energy when it is turned. This rotation can be generated by various sources, such as a turbine powered by water, water vapor, wind or even an internal combustion engine. The main idea is to transform the mechanical energy of a movement into electricity through a process called electromagnetic induction.

It is worth noting that there are different types of generators, and the specific construction may vary depending on the application and desired characteristics. Let's focus on basic electrical generators. At the heart of a generator are the coils or winding of conductive wire and this winding is often made of a conductive material such as copper.

These coils are fixed to the rotor shaft, which in turn is the rotating part of the generator. As the rotor rotates, the coils move, and an electric current is generated through the phenomenon of electromagnetic induction. However, to induce current in the coil, a magnetic field is needed.

This field can be generated in different ways, depending on the type of generator. In traditional generators, a permanent magnet or an electromagnet is used to create this magnetic field. The stator is the stationary part of the generator that surrounds the rotor with the coils.

It is what contains the fixed magnetic field, which interacts with the rotating coils. The stator is also responsible for keeping the coil in rotating motion, using bearings, for example. On older generators or direct current (DC) generators , there may be a device called a commutator.

It is responsible for reversing the direction of the electric current generated by the coil, ensuring a direct current output instead of alternating. In this type of older machine or direct current generators, brushes are used to establish the electrical connection with the commutator. However, in many modern generators, especially alternating current (AC) generators, brushless devices are more common.

On the other hand, a motor is a device that converts electrical energy into mechanical energy. Instead of producing electricity, a motor consumes electrical energy to generate mechanical movement. A common example is the electric motor found in many household appliances, electric vehicles, fans, and many others.

This type of engine uses the opposite principle to that of the generator, called electromotive force, to generate a magnetic field that interacts with the electric current, thus creating a rotary movement. There are different types of engines, each with its own specific construction. We will focus on alternating current (AC) and direct current (DC) motors, which are the most common types.

In a direct current motor, the rotor is the rotating part containing the coils that rotates in the magnetic field. The rotor is often referred to as the armature, and electrical current flows through the coils in the rotor. The stator is the stationary part of the motor, containing the field windings and these windings create a fixed magnetic field that interacts with the rotor when electric current is applied.

In DC motors, the commutator is a critical component. It reverses the direction of the current in the rotor coils, ensuring that the magnetic field in the rotor always interacts with the magnetic field in the stator, generating continuous movement. The brushes are conductive parts that establish the electrical connection with the commutator.

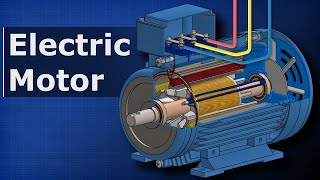

They keep the electrical current flowing in the correct direction to keep the rotor moving. The engine is often housed in a casing to protect internal components and provide structural support. In alternating current motors, the rotor can have different shapes.

It can be a squirrel cage rotor, which is a cage-shaped conductive metal structure, or a field wound rotor, which is similar to the rotor of a direct current motor. As with a direct current motor, the stator contains field windings that create a fixed magnetic field. However, in AC motor, there is no commutator, and the change in the direction of current is achieved by changing the polarity of the AC supply.

As with DC motors, the housing provides protection and structural support to the AC motor. Some AC motors, such as asynchronous motors, use specific rotors, such as the squirrel cage rotor mentioned earlier. You can see that the constructive form of motors and generators is very similar.

So what differentiates a motor from a generator is just that one consumes electrical energy to generate mechanical energy and the other converts some type of mechanical energy into electrical energy? Well, we have some differences that are worth exploring and one of them is in relation to commutation. In direct current (DC) motors, the commutator is often used to reverse the direction of the current in the rotor, ensuring continuous movement.

However, generators generally do not have commutators, especially alternating current (AC) ones, and the direction of the current generated is naturally alternating as the rotor rotates. As I already said, many direct current motors use brushes to maintain the electrical connection with the commutator. However, modern generators, especially alternating current generators, are often designed without brushes, using technology to prevent wear and friction.

Another point is speed. The speed of the motor can be controlled by varying the electrical current supplied to the rotor, that is, we have a certain control over its speed. Normally it has heatsinks and forced ventilation systems to cool the motor already coupled to the shaft, that is, it cools itself.

The speed of the generator is directly influenced by the speed of the mechanical source that makes it rotate. So, in order to control the speed of the generator, we have to control the speed of the mechanical source, and its cooling ends up being done by heatsinks in the housing and even having a separate system for cooling it. This is because the dissipation may not be sufficient, and the rotation may be low to be able to cool the system itself.

But can I use a motor as a generator? Well, analyzing all the general requirements for assembling the system, especially with the use of charge controllers and even protection systems, yes, you can use a motor as a generator. If we take these little motors and rotate their axis, we will see that we can already produce current to power small LEDs, for example, but the issue is that the friction generated by the brushes in the commutator ends up being very large, and a lot of turning energy is lost in form of friction and heat.

But for example, in electric vehicles, the engine used to move the wheels is also used as a generator in regenerative systems during braking. In other words, when we step on the accelerator, the engine works as an engine, and when we brake, this same engine works as a generator to charge the batteries. However, it is important to understand that these motors usually work with alternating current, and do not have brushes, which increases their efficiency and reduces the friction and heat generated.

So, did you know these differences between generators and engines? Do you have a generator in your house? Do you have a spare engine lying around?

Leave it here in the comments, I want to know Here you have two video options that you might like and that are worth checking out to expand your knowledge. And if you want to contribute to us, leave your like, subscribe to the channel, activate the bell and consider becoming a member of the channel.

Related Videos

10:03

How does an Electric Motor work? (DC Motor)

Jared Owen

20,520,642 views

13:24

What is a CAPACITOR? Understand how CAPACI...

Engenharia Detalhada

194,769 views

13:30

INFINITE energy through PERPETUAL movement

Metal Projetos

2,003,775 views

16:33

MOTOR elétrico - Como FUNCIONA um motor TR...

Mundo da Elétrica

597,677 views

12:22

Qual a diferença entre TRIFÁSICO, BIFÁSICO...

Eletricidade Online

213,079 views

15:34

How Electric Motors Work - 3 phase AC indu...

The Engineering Mindset

6,794,504 views

19:40

Quem Inventou o Motor Elétrico? Como Era o...

Invenções na História

924,714 views

33:22

Tudo que você precisa saber para comprar u...

LetraJota

443,384 views

13:45

Motor Tesla Modelo 3 - A Engenharia Brilha...

Lesics português

1,380,153 views

13:23

Marco Rubio SLAMS Woke CBS Host over "STUP...

Preta Moraes

1,225,911 views

8:06

Differences between AC MOTORS and DC MOTORS.

Engenharia Detalhada

186,203 views

16:27

Qual a diferença entre volt, watt e ampere...

Manual do Mundo

3,673,717 views

23:29

✅ O MAIOR DO SÉCULO 19!

Biblioteca do Cérebro

63,023 views

14:41

How 3 Phase Power works: why 3 phases?

The Engineering Mindset

2,584,978 views

11:55

Understand the differences between an elec...

Verve Científica

64,394 views

12:36

Building a Generator

Tim Station

1,614,499 views

10:15

What is URANIUM? Uranium: From Mining to E...

Engenharia Detalhada

1,060,245 views

33:35

NEW FREE ENERGY GENERATOR 20KW - FREE ENER...

The Liberty Engine Project

2,501,501 views

17:31

MOTORES ELÉTRICOS: Tudo o que você precisa...

Sala da Elétrica

78,041 views

11:06

Genius Contactless Motor Could Change Tran...

Ziroth

759,017 views