who wants to see the most precise measuring machines in the world I've been invited to nist the National Institute of Standards and Technology on campuses just outside Washington DC and another in Boulder Colorado there are thousands of scientists who do an incredible amount of research and standard setting across a vast number of areas with the goal of supporting American industry if you're in the United States so much of your life is traceable to nist the tick in your clock to the marks on your ruler are just the beginning of how you are impacted by their

work but I wanted to see some of the machines that are the best the absolute most precise machines in the world the machines for which there was no machine of Greater Precision for the kind of work that they do these are the machines which are at the absolute top of the Pyramid of traceability for certain kinds of artifacts which makes these machines insanely important because of the vast Ripple effects they have through American industry because their Precision is so vital they are directly calibrated against the laser which serves as the standard of measurement in the

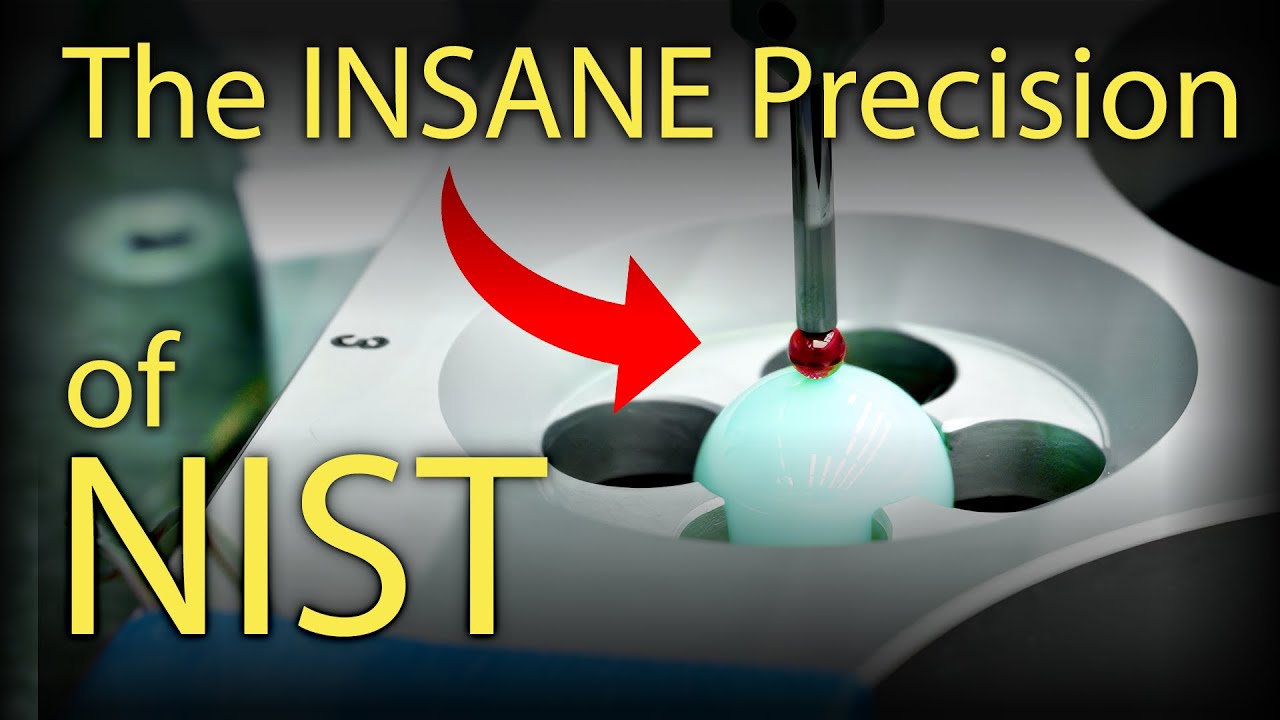

U.S in particular I wanted to see the more M48 coordinate measuring Machines of which nist currently has two running and there's another on the way I'm showing here an animated nightmare situation so later you'll understand how incredibly problematic this is these machines work very simply by using a touch trigger probe which can move around apart in three dimensions though in the animation it's moving much more quickly than in reality thanks to Decades of work they can work in a large volume and measure artifacts from less than a millimeter to a meter or longer and the

shapes can be three-dimensional so they can measure anything that can fit on the table and they do it all with the level of precision that is just really incredible no really seriously we'll get to that level in a minute but first let's meet Jon in the primary machine my name is John stelp we're in the uh the uh CMM Suite of Laboratories at nist we're about 80 feet underground since about uh 1999 I've been working pretty much full time on the the more reported measuring machines all of these things have to be done at a

really high level to give the machine a really accurate scale you put in a room that makes it move extremely repeatably and you play a lot of tricks with the data collection and what you end up with in the end is some of the best supported measure machine 2D 3D measurements in the world and they're accessible to any company in the United States who's willing to send artifacts here this one is the primary this is the one I've worked on for about 25 years the machine uses a laser scale which is also very unique for

coordinate measure machines there's a single laser in the back and that laser being the split in the equal pieces and what we have here are uh interferometry Pathways for the motion of the table is done in here inside this tube is for the motion of the carriage and behind the um the ceramic Ram is another open beam path for measuring the motion of the the ceramic as it moves upwards so by using very Precision screws which is what these machines are really designed around we use the screws to help push and pull the parts of

the machine that we're moving but we use the laser to know exactly where we are we don't use the accuracy in the screws themselves which is a very important the device that you see on there right now is actually sort of one of our mapping devices which is basically a plate with ceramic spheres and what we do is we measure with the machine where these sphere centers are in the 2D space and by knowing ahead of time or by doing some algorithm rotations we can actually calculate uh how close the machine measures the sphere centers

to the known's spaces in space in a sense it's sort of a mapping process a tool to measure accuracies of the machine 2D space in these two axes but we can measure Small Things tiny very small sub millimeter uh artifacts all the way up to meter-sized things with about the same accuracy so you might be asking why does John keep talking about metric units when we here follow the US customary system well here's where I again remind you that the inch is defined by the meter so the inch is really just a weird metric unit

but this is why nist is working in metric units here because it's the fundamental standard in a moment I'll tell you the absolutely crazy resolution this machine can measure to but I want to quickly go over the incredible lengths that nist has gone to to get these kinds of measurements the machines are 80 feet or about 25 meters underground to completely isolate them from the outside environment the room temperature is controlled to about plus minus 100th of a degree celsius which by itself is a remarkable achievement it's actually showing below the standard of 20 Celsius

here because we're in the room and it's trying really hard to compensate for our heat so what we're really trying to do is put these machines in an environment that is as impeccably stable as possible speaking of temperature and I didn't mention this before but on the surface plate with the artifacts being measured there are also extremely accurate temperature probes placed around the part so even the tiniest difference in temperature can be fed back into the computers and accounted for the humidity and air pressure are also extremely closely monitored and fed back into the computers

so the exact index of refraction of the air is computed so the laser interferometry system is superbly precise the machine itself even though it weighs tens of thousands of pounds is on an air cushion vibration base so all vibrations are eliminated so you can actually move the machine you look at it I can see a tilt just by moving by standing on vibration so it's on some air pads to keep it nice and level and isolated from any other vibration that's still down here in laboratory any potential sources of heat can be eliminated like the

computers and the motor drivers electronics are all moved into a different room it took 10 years of learning this machine just to get it ready for commercial use and has been further refined over 20 years it has to run in the dark because even just turning on the lights would introduce too much uncertainty not only can the lights not be on but it takes the room hours to stabilize in temperature after people have been in it even just for a few minutes as tight as a thermal control that we use on the machines for in

here what we've done already has sort of Knocked and Sheen out the rest of the day the computers also have a sophisticated error map of the machine so that when a part is measured in various ways practically all physical errors can be removed in software the machines themselves aren't perfect they do have motion arrows but in these kinds of rooms and with these types of of instrument designs the Motions are extremely repeatable so if the machine has a little wiggle the important thing is that it Wiggles the same way every single time it moves that

way if it does we can measure that wiggle and then using the the computer operating system make a correction for that wiggle so that the machine we'll still wiggle but the computer thinks it's moving perfectly they had to remove even the sheet metal from the machine in some places because the tiny differences in temperature behind the metal would ever so slightly but measurably warp the huge pieces of cast iron that weigh many tons and also very importantly you have to know how the customer is going to use the artifact so you can fixture and measure

it in a way that's useful to them okay one last thing before we move on and really blow your mind with what nist can do looking at a bunch of zeros doesn't make sense unless you put that into perspective one million seconds is about 11 and a half days one billion seconds is about 31.71 years that's a big difference when you start talking about this level of precision you're talking nanometers which is billionths of a meter which is incredibly small we all know A millimeter is already pretty small and a nanometer is one millionth of

a millimeter a sheet of paper is about a hundred thousand nanometers thick a red blood cell is about eight thousand nanometers in diameter the average bacterium is about a thousand nanometers long the covet virus is about a hundred nanometers in diameter and smaller viruses are about 30 to 50 nanometers the size of a strand of hair is really quite small so what we have over here is a very interesting device that measures diameter so this is a nanometer display so basically I have a strand of hair in the machine between the two jaws and down

here we can see that that hair is about 64 000 nanometers in diameter so we're about 64 micrometers so to give you an idea of that the accuracy of these machines is if we took that hair and we cut that into 3 000 pieces across like not not long but lengthwise we cut in the 3 000 pieces lengthwise this machine is accurate enough to one of those pieces so it gives you an idea on a machine this size which is really quite a large machine the kind of accuracy you can get in these kind of

environments so if you do the math on that 64 000 divided by three thousand gives you about 21 nanometers which is absolutely incredible but I talked to John Moore later and he told me you can even do better than that and repeatably get down to a stunning 10 nanometers under ideal conditions that's right in the relatively huge working area of this machine even with weird irregular 3D shapes this machine can measure points in 3D space with very little uncertainty down to much less than the diameter of a small virus and that blew my mind to

put this in perspective your fingernails grow about one nanometer per second in the time it took me to say these two sentences your fingernails grew about 10 nanometers now while that's amazing and it can repeat that measurement all day long on an artifact that distance is so small that's not practical to use it even if you look at it and I mean that literally if you turn on the lights it would become invalid and if you move or we fixture it you will not get that same measurement again due to incredibly small changes in the

setup the accuracy is around 50 nanometers that is if you're in inches that's a that's two millionths of an inch which is extremely small and when you really understand the air resources on a machine like this you know how to sort of design a measurement method that can take into account all of the errors in the machine you can even do better than that sometimes so a practical Precision is in the 50 to 100 nanometers range depending on what the customer needs which is still absolutely Bonkers no one else can come close in a large

general purpose machine like this now all that effort is put to extremely good use like I said before John his team and this machine are at the top of a huge pyramid of precision that trickles down into a tremendous number of products that you use all the time because this machine is effectively the practical definition of measurement that is used to certify artifacts that are then used to calibrate other measuring machines which in turn certify countless other machines and measuring devices the ripple effect of these machines Permanent American industry in our military in very profound

ways every time you get an American-made airplane or car there's a little bit of the M48 in those but countless other things as well every major industry in the US has Master artifacts certified at nist and many of them are done on this machine and by John without ever knowing it you can trace all sorts of things directly back to this machine so now you understand why this is such a nightmare situation because the environment is completely uncontrolled even if you have the highly tuned machine in this kind of situation you introduce so many uncertainties

into your measurement the quality of it vastly decreases and that's what I want you to take away from this if you don't have everything else that's needed in the long chain of removing as much uncertainty as possible your measurements need to account for how much is possibly wrong and how far off you might be and even measuring your uncertainty is a very complicated thing that nist does extremely well uncertainty statements are too complex to get into here but maybe some other time and this is just the beginning of the amazingly incredible High Precision work that

nist does across so many areas seriously this should get a lot more attention for the best in the world kind of work that they do there are so many more stories that could be told here and maybe I have a few more to go a huge thanks to John and the other wonderful people I met at nist for showing me the more M48 coordinate measuring machine and giving me a little peek into the tippy top of traceability here in the U.S he's a really National Treasure types of instruments I mean the other countries don't have

these and we we have them and the US should be uh should be proud of that because the the work that can be done on something like this um is unparalleled uh around the world so it just provides the United States industry with just a little bit of extra uh support so what do you think did you think a machine like this could measure so accurately across such a large volume let me know in the comments I'd love to hear what you think this video from machine thinking is brought to you by the wonderful people

on my patreon notice the lack of mid-roll ads or that I don't have sponsors I'd like to keep it that way and my patreon is the primary way to support the channel we'd love for you to join us too patrons would get to see a lot more footage from my time with the more machines and yes there are more than just the one and hear a lot more about the stories about how John operates and how things work on my patreon I post regular updates on the progress of content or behind the scenes info that

had to be cut but it's just too interesting not to share at the six dollar level and up you get goodies like these blender models I made for this episode who doesn't need a 3D model of the nist more M48 coordinate measuring machine or some parts of a random Conservatory I made plant's not included because of license reasons there's other fun stuff too so please check out the sign up page and lastly you're subscribed right you should really do that if you haven't already as always if you liked the video thumbs up if you didn't

like it double thumbs down thanks for watching I'll see you next time