Motor a Vapor um Projeto para Feira de Ciências

616.39k views1295 WordsCopy TextShare

Com Ciência Tranquila

Projeto de um simulador de motor à vapor que usa o ar de seus pulmões para funcionar. Faça você mesm...

Video Transcript:

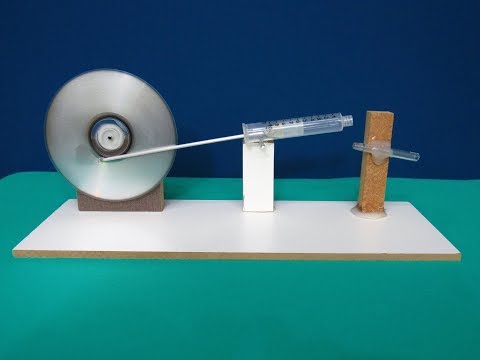

Hello guys! In today's video we're going build this little engine that can be built at home with easy obtainet materials Can be used at a science fair to explain the operation of a steam engine This engine has the advantage of using air from lungs instead of steam which makes the project much easier to build and safer to use For this project we will need a CD a pipe with a diameter between 1. 5 or 2 centimeters and about 9 centimeters in length.

don't try to use something very different of these value We will also need sticks and straws, pieces of wood to fix the equipment hot glue and super glue. we will still need about 1 meter of silicone hose We will also need a thick wire, telescopic antenna tubes and a gear to be glued to the center of the CD Alright! this gear that will be attached to the center of this disc fits perfectly with the antenna tube Then it can easily rotate around this tube This gear will then be attached to the CD so that it can rotate freely around this axis Now let's paste this gear into the center of the CD We finished gluing our gear, it was very well centered.

And now our tube fits perfectly into our gear. Now the CD can spin freely. To prepare our syringe, we will remove this rubber from the piston and enlarge the syringe tip hole Let's make this hole a little bigger For this I have a metal tube that I will warm and insert into the tip of the syringe Now using a hot wire we'll drill a hole two centimeters away from the center of the disc Now we will fix our disk for this we will use this piece of wood and we will hold this other piece of wood in that position using hot glue Now the shaft of our disk will be glued to this piece of wood using hot glue Ok now we can cut what is left of the tube Very carefully Our shaft will be fitted like this Alright, now we'll take a piece of wire and we will make a 90 degree bend to fit with the hole of the CD With the help of pliers it is possible to make this bend that will be fitted here.

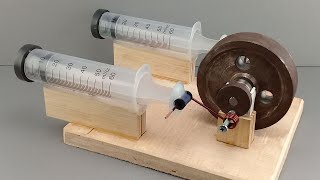

And it will allow us to make this movement. And as the piston goes back and forth, this disc will rotate. We will only need a part of the syringe Then we will remove part of it with only one end of the embolus remaining.

In it, we will fix the wire. So let's cut here. The remaining part will only serve to allow the piston to slide back and forth and prevent it from turning inside the syringe tube.

Now, let's put our wire here and put it inside the syringe again. For this I will position the syringe 3 centimeters from the disc and I will cut the wire at the end of the syringe. I will mark here.

And let's cut the wire at this point Again, with a hot wire, I will drill some holes in the syringe piston I also made some grooves on the wire end to glue it to the piston using hot glue Now, let's cut about 2 centimeters of a hard plastic tube This straw will serve so that I can put a piece of that wire inside it. A metal pipe can also be used as long as the wire can get inside it. In my case, the metal tube will not fit.

So, I will cut 2 centimeters of this straw approximately and it will be glued to the syringe piston. I recommend using superglue for this. So let's stick this straw perpendicular to the body of the syringe.

Like this. I do not recommend using hot glue as heat can warp the body of the plastic straw and it can warp the syringe as well. So I will use superglue for that.

Now that our straw is well glued here, let's connect a syringe to the piston and let's fix this piece of wood that will support the shaft that will be attached to the syringe. I'll hold everything here with hot glue So that this movement is possible. It is important that the shaft remains completely parallel to the disc so that the movement has no locking.

It would be good to drill a hole in a piece of plastic about the diameter of the wire. After drilling the hole, make a cutout to get a smaller piece. This piece of plastic will be used to secure the ends of the wire to prevent the syringe from escaping from its axis during movement and the wire from escaping from the disc.

Then it will be secured as well to prevent the wire from leaving the disk while moving And this is the movement that we will have However, for this movement to be possible, we need to inject air into the syringe. So, I'm going to attach a hose here so I can blow air in here The hose will be positioned so that air can sometimes enter the end of this syringe To better direct air into the syringe, I will use a pen tube attached to the silicone hose. And I will position all this using a piece of wood This part of the assembly is more difficult.

Because we must find the exact position of the tube so that the piston is pushed back from the moment it is in the position where there is no air inside the syringe So I must be injecting air into the syringe at the exact moment. Then I will position the tube in that direction And from this moment the tube begins to receive the jet of air into it. As the piston moves away, the disc will change position, which raises the opening of the syringe.

And it will recieve air when it is in the starting position. This way the syringe receives the air jet at the exact moment After that, the opening of the syringe must be open so that the air in it is expelled. Therefore, you must find the best position.

Now, let's do a test before fixing everything. Alright, this seems to be the correct position Now I'll fix with hot glue Well now that our motor is fully assembled let's couple our silicone tube Now let's take a breath to see if it really works Well, if you intend to make such a device for a science fair Take care and do it with a small syringe. We use a 10ml syringe.

Do not believe that bigger equipment works better. We built a very large piece of equipment but unfortunately no one can blow it enough to set it in motion. The most we could do was two or three turns.

So it takes a lot of air. And believe me, we have no lung capacity to propel one of these if it's bigger. So do it with a 10ml syringe or a tube compatible with these dimensions.

Another reminder If this is used for a collective presentation this hose you put your mouth on, no one else can. You must not leave the equipment exposed for anyone to put their mouths on the tube. This can transmit diseases.

So have some alcohol on hand to sterilize the equipment if you need to leave the equipment for a while. You don't know what they did to the tube while you were away. It is not?

So that's it guys! I hope you enjoyed this video Until the next!

Related Videos

14:30

DIY - How to make a homemade Alpha Stirlin...

Manual do Motor Stirling - Leandro Wagner

3,293,676 views

18:29

TRABALHO DE CIÊNCIA. COMO FAZER UM MOTOR ...

Geral Na Prática 💡⚙

582,402 views

10:13

Make an Amazing Laboratory Distiller for s...

Inventus

9,194,710 views

12:52

NOVO MÉTODO REVELADO. CIÊNCIA CURIOSA. Mot...

Geral Na Prática 💡⚙

211,053 views

3:24

Making a Stirling Engine from a Coke Can -...

inventor Man

179,781 views

10:38

AMAZING ELECTRIC MOTOR WITH ALUMINUM CANS ...

Inventus

5,341,601 views

18:07

Honey, I Shrunk the Steam Engine

Chronova Engineering

314,439 views

15:48

Destroying Lego Towers

Brick Technology

13,529,541 views

13:30

INFINITE energy through PERPETUAL movement

Metal Projetos

1,422,089 views

12:01

Unbelievable: I Forged A knife From Concre...

Random knives

7,726 views

25:05

High pressure non-electric water pump - Ne...

Yt Crop - DIY Crafts

8,391,255 views

7:07

Simples Transmissor de Energia Sem Fio - F...

Com Ciência Tranquila

127,459 views

19:20

Best Oddly Satisfying Videos 🔥❤️ Incredi...

OMG

67,811 views

10:18

Making a Steam Engine

Maciej Nowak Projects

5,408,208 views

8:13

Make a Simple Steam Engine Project for Sci...

Inventus

449,142 views

20:10

FANTÁSTICO! #COMO FAZER UM MOTOR STIRLING ...

Geral Na Prática 💡⚙

15,599 views

11:51

how to make double cylinder engine 100% wo...

3 Technology

198,853 views

8:32

DIY Steam Engine Generator At Home - This ...

Vida em Silício

2,301,082 views

25:00

How to make a stirling engine

foguista

673,698 views

5:33

MOTOR DE VAPOR CASERO

Darry tools

3,221,460 views