What is a PID Controller?

1.4M views677 WordsCopy TextShare

RealPars

▶ Want to learn about industrial automation? Go here: https://www.realpars.com/individual-pricing

▶...

Video Transcript:

welcome back and thank you for checking out this latest video brought to you by real pars today you will learn about pids specifically what they are and when do we use them with automation and PLC's [Music] before we get into today's video if you love our videos be sure to click the like button below and make sure to click Subscribe and the bell to receive notifications of new real Parrs videos this way you never miss another one so what is a PID controller it is an acronym that stands for proportional integral derivative if you need

to keep something constant like a temperature for example then this is the way to do it essentially it uses a control loop feedback to ensure the output wanted is what you will get simply you put a setting in the controller and it will keep the output constant based on feedback from some input typically some kind of sensor something you probably encounter everyday that is essentially PID control is your cruise control in your vehicle first you get to the speed that you want to be going then you set your cruise control the cruise control sends output

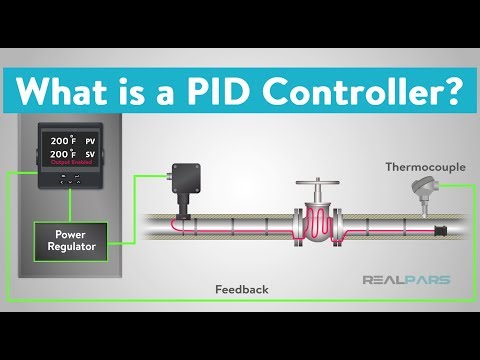

signals to your throttle to regulate the speed a speed sensor provides your control loop feedback to tell the crews if the car should speed up or slow down or how much more or less throttle to provide a common standalone type that we use in manufacturing an industry is a temperature controller PID these controllers are pretty simple to use and set up plus they do a great job at controlling temperatures of a variety of equipment let's take a look at how they work for our example we will look at a PID controller that controls the temperature

of heat tracing on process piping first we need to enter a set point 200 degrees Fahrenheit for our example now the controller will give a signal to the output to start heating up the heat tracing the control loop feedback is in the form of a thermocouple to read the temperature for our example the PID controller can work as an on-off control for the heat tracing along with the set point of 200 degrees we will set the controller at a couple of degrees above and below 200 as well when the thermocouple reads 202 degrees it will

turn the heat tracing off when it reads 198 it will turn it back on this is the simplest form of PID control we also have the option of setting up a PID controller with a PLC instead of the standalone unit we can use the input and output cards already on our PLC the process variable or control loop feedback would be wired to our input card and programmed into the PID our output being controlled is wired to our output card the PID and the PLC can do all of the math and make the decisions based on

the variables and set points no matter which way you decide to set it up a PID is an excellent choice for an automated process let's look back at today's information a PID controller is a proportional integral derivative controller it can keep an automated process like temperature pressure or flow constant for you automatically P IDs use a control loop feedback or process variable to monitor where the output should be these usually come in the form of sensors and meters pids come in many different forms including standalone units and PLC programming we can use our input and

output cards along with programming software to set up a PID I hope this video really helps you get a grasp of how to use a PID they are a very handy tool to use don't forget to click the like button and subscribe so you never miss another real Parrs video want to learn PLC programming in an easy-to-understand format and take your career to the next level head on over to Rio parse calm [Music]

Related Videos

7:33

What are PID Tuning Parameters?

RealPars

300,069 views

9:25

PID Controller Explained

RealPars

826,878 views

15:11

Programable Logic Controller Basics Explai...

The Engineering Mindset

2,024,043 views

11:42

What Is PID Control? | Understanding PID C...

MATLAB

1,809,602 views

13:13

PID Balance+Ball | full explanation & tuning

Electronoobs

742,606 views

5:20

What is a VFD? (Variable Frequency Drive)

RealPars

1,351,495 views

6:13

What is a Control Valve?

RealPars

309,378 views

22:19

What is a PID Controller? | DigiKey

DigiKey

77,251 views

6:00

PLC Basics | Programmable Logic Controller

RealPars

1,219,900 views

4:41

Controlling Self Driving Cars

AerospaceControlsLab

505,760 views

10:08

What is the Difference between Absolute an...

RealPars

790,447 views

10:33

PID vs. Other Control Methods: What's the ...

RealPars

121,352 views

14:13

How PID Control Works - A Basic PID Introd...

Instrumentation & Control

30,977 views

9:33

How Pneumatic Control Valve Works | Contro...

Upmation

751,359 views

15:45

What is a Servo Motor and How it Works?

RealPars

2,069,225 views

5:28

What is the Difference between Profibus an...

RealPars

773,078 views

13:12

How to Program a Basic PID Loop in Control...

RealPars

379,155 views

13:07

PIDs Simplified

SiieeFPV

294,634 views