Engine Building Part 2 - Gapping Rings, Installing Pistons in a 350 Chevy

682.44k views2805 WordsCopy TextShare

Pete's Garage

Ring Gapping, installation, piston installation, checking for crankshaft binding. 350 Chevy small bl...

Video Transcript:

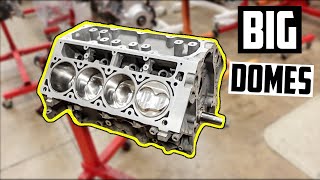

[Music] everyone thinks stopping my piece garage well it's time to gap our piston rings install our piston rings to the Pistons and put the pistons in the assembly put them in the block and get a rotating assembly finished let's get started now what we're going to be installing in this engine since we're not looking for some huge horsepower numbers we're gonna be installing a cast aluminum hypereutectic aluminum piston flat top piston with the four valve release now the cast aluminum or the hypereutectic aluminum all that means is that the aluminum has a little more silicon

in it which gives it a lower coefficient of thermal expansion so we can use tighter tolerances here and some of the benefits are there of using that type of material it's lighter and weight and it's lower in cost so these aren't too expensive and also have the coated skirt on here the coated skirt makes it nice and easy to install and it makes it believe it or not that produces noise and piston slap it's pretty short piston so it's not another really tall piston connecting that to an Eagle rod these are Eagle Eagle SAR 51:40

steel rods a forged forged eye beam rod as steel the 51 40 and it comes with the ARP 8740 cap screws and they're really nice to shot peened and they're really balanced fairly well they're plus or minus two grams so they're really pretty accurate and I have the also have a machine shop install the Pistons on the connecting rods and haven't put them to the Pistons to the wrist pin there because when they balance the rotating assembly they have to have all the stuff done and they balance it all for me so let's put the

Rings in what we're gonna be using for this engine also is a is a hastings chrome as steel moly ring nothing fantastic but it's a really good ring so let's get these rings and we'll put them on the pistons and get them installed all right now piston rings you guys always hear me talk about planning your engine and doing all your homework up front but if you do that this is what makes it easy if you are able to bore a cylinder standard oversize like 30,000 makes it very easy to buy a set of rings

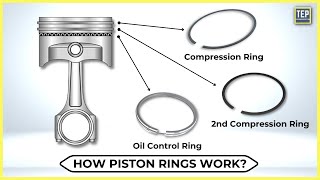

that are pre gapped and you won't have to do much grinding or actually no grinding whatsoever I'm using these Hastings brings as a steel moly ring this is the top ring or the first ring this is the second ring that goes underneath now we're gonna gab these really quick and a couple things to notice orientation is important which way goes up is important now this the top ring is completely square or rectangle there are no identifying marks on it anywhere there's no dot so it doesn't matter which way is up on this one it's pretty

symmetrical all the way around actually it is symmetrical all the way around the second ring that goes in you can see has a chamfer on the inside here which may be tough to see you may be able to see it or not see it but there's a chance for here but it also has a dot you can see the dot right here and this dot indicates that this part of the piston ring goes up the dot always goes up on a piston ring so let's check these gaps real quick and all you have to do

is insert it in the bore and I'll put it let's see I'll put it this way so you're able to see how to do it and the what I'm going to do is I'm gonna take a piston here and I'm just going to level it out or level out that ring in there so there's nice and flat and I'm sure that my my two gaps there are touching alignment there now the distance or how much gap should you have in your ring the rule is three and a half thousand for every inch of cylinder bore

these bores are just over four inches because it was bored out thirty thousand so I want to have at least fourteen thousand probably no more than twenty thousand on my gap so I'm checking my gap right here and I'll start at fourteen thousand which is good it's just about fits in there and what I'm gonna do is I'm gonna jump right up immediately to twenty because I want to have 40 and I want to have less than twenty so I'll try and put the twenty in there and the twenty does not go in doesn't go

in easy but let's just for the hell of it see what it goes down to let's see if the 19 fits in there the 19 is a little bit tight let's try the 18 and the 18 the the 18 does going so about 18,000 not bad for the first ring so let's take the first ring out and let's do the same thing with the second ring again the dot goes up I'll take this and most of this in here oops let me put it this way so you can see turn this I'll get the piston

I'll use the piston to get it nice and flush so that the gaps are even or the ends of the piston are the same distance which makes it easier to check so again I'll start let me get my gauge here my feeler gauges you want to have at least 14 and the 14 goes in and I'll jump immediately up to 20 make sure we're not over 20 and the 20 doesn't go in at all so let me drop down let's see now let's try 17 and the 17 goes in jump up to 19 19 just

about goes in will nice check with that 20 and the 20 doesn't go in so it looks like the gap is 19 so we're within limits for the gap and gap on the piston rings so again when you plan it out you're able to buy your piston ring and it eliminates you from having to grind your ring now you can custom fit or you can have the zero fit and ring which overlaps instead of having a gap it overlaps there's all kinds of things you can do but for this engine 350 we're not looking at

a huge horsepower standard ring standard bore standard size piston the more standard you can go with parts the cheaper it's going to be and the easier it's going to be to fit these components without having to do a custom work now we can put these rings on the Pistons okay guys now putting Pistons in and doing this part of the job I like to do it all at one time meaning I don't want to put the rings on the Pistons and set them down and then pick them up and put them in and set them

down and do something else set them down I want to try and do it all at one time so I reduce the risk of dropping it or damaging the piston that's the most important thing now a couple things to note here when you put the piston in the bore the part here with a chamfer on the rod that's got to face the counterweight so this faces the front of the engine okay see there's an F on there for the on the piston says F there's also a dot so that dot faces the front so I'm

going to start by putting my rings on first I'm gonna put on my oil wiper and wrap it around and if you remember some other videos you want to make sure that you lift up this edge you don't want to drag it across the front so I just lift up just a little bit and just put it there now if you're going to you want to clock the rings and clocking them means you want to have them in different orientation you don't want to have all the gaps in one spot so I'm going to take

this in the maternity bottom oil rail I'm going to put that that opening right here again I'm just going to bring that around and I'm gonna lift up over my wiper okay now there's my gap for that I'm gonna take that I'm going to turn that one-third I'll take the top wiper the top oil rare oh I'm sorry put that in around and I won't drag it on the piston I want to scratch the piston so I'll lift it up a little bit I'll put that right in place so now I have that right there

now here's the front of the piston so I'm sorry the front of the engine and I have my my gap right here for my third so I'm gonna start my first ring I'm gonna take this in turn this back just the third and I'm gonna put my second ring on the bottom ring and if you recall this that's the first ring the bottom ring is the one that has the dot on it the dot here this dot has to face up just like this so since I'm left-handed on to be doing it this way and

use my piston ring players and you want to use pliers because you don't want to force it on there you can crack ring if you crack ring out to buy a whole new set so I'm gonna put that in there I have to my slot I'm gonna orient that gap so that I'm gonna find here's my top third okay right there there's that one and now since I have this gap over here I'm gonna have the other gap over here which will line up nicely when I put this ring on the top ring just like

that okay so now my rings are all clocked as soon as I put them on there and I'm gonna make it easy on myself I'm gonna put this right in the cylinder I have the cylinder already prepped with some oil around the cylinder I'll put my piston ring compressor on the piston that I've been using this one for quite some time it's almost time for you uh ring compressor okay I have a little bit of Lube in there to make it easy to come out again chamfer the dot facing forward I'll set that in the

board just like that after tickles make sure that the ring compressor is nice and flat around the block one motion I push it all in just like that now I'm going to turn it over and I'm gonna immediately put that cap on Lube that bearing and tighten it to the crank all right no on the bottom of the engine got my crankshaft out of the way here because I had my connecting rod right here as you can see and what you don't want to do is push this piston so far down where the connecting rod

comes and hits your crankshaft because you will put a nick in there for sure so while this I have a ton of room in here I could put my whole hand and there's a lot of room I'm gonna put my bearing in place my lock notch is at the top here so I'll line up my lock knotch put my bearing in like that and I'd like to put some hold out there just put a little bit of Lube knight on the bearing this up here out of the way it doesn't fall off like last time

like that and I'm going to push the piston down so that it lines up with my pin on the crankshaft and I will do this very small to make sure I don't Nick it standing it very slowly okay there we go it's all the way down no I can take this and turn like Frank wrapped around its like that so I can see my connecting okay up my bearing cap I'm gonna put some lube on the bearing there's a little bit a little in that and since we're using these ARP fasteners I'm gonna use the

ARP the ultra torque the ultra torque loop goes on the on the fasteners on the threads and you can't put it underneath the the head of the bolt if you like you don't have to but you can and when you line this up the lock notch is on the top lock notch lock notches match up put it on in there laying these up and these are the what is the 8740 ARP fasteners so these go to 40 foot pounds so I'm going to torque it right away trying to show you the whole processor so you

know how long it really takes instead of that you know chip foose built the whole car in one hour kind of thing and 40 foot pounds let's get a nice and snug first get them both nice and snug yeah you can hear those flip those footsteps walking away okay we're almost there here we go okay 40 foot palms 140 foot pounds what you don't have to do is I've seen guys do this with a torque wrench they put it under you like this ago that doesn't do anything all you need is one click when you

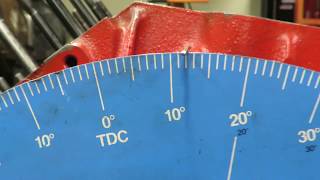

go there and you reach one click its torque you can stop clicking it five times all you're doing is wearing out in four okay know what I'll do is I'll just take the crank and I'll just drop the wrench again and I will rotate just to make sure this piston is not binding up and it moves nice and smooth no binding up whatsoever now all I have to do is repeat that seven more times and we'll be good yeah it makes a okay quick check one three five seven two four six eight they're all numbered

the dots are all facing forward on all of the Pistons they're all in the correct orientation we give it a quick trip over and it turns over nice and smooth nothing's binding clicking no noises now we'll take a quick look underneath let me turn this over we'll take a quick look and I'll show it to look for for common problems if you do this in you have problems where it's it's sticking or it's binding up okay looking at the bottom here as you turn it over if you have any binding whatsoever the first thing you

want to look for is to make sure you have your connecting out rods on right if you don't have any play in here whatsoever you might have the rod backwards if the rod is backwards and the chamfer is facing the other way the rod is gonna dig into the fill it on the crankshaft it'll cause these to bind up that's the first thing you want to look for then after you're done installing them if you subbed binding look to make sure you don't have anything that's sticking up that might be hitting the block sometimes if

you leave a forget to put up the bolt then all the way it'll come up and sometimes it is you have a closed clearance on your block the the nut can come up and hit the block and your locking up so just give it a flip look over but this one is turning over nice and it works awesome okay the ruling assembly is finished now it's pretty simple if you work neat and you work in order you should have no problem whatsoever and it doesn't hurt to go back to check the torque on all your

rod bolts to make sure they're all tight just in case you miss when it happens on occasion now next week moving to the top end with the cylinder heads and the rocker arms and the hole lifter assembly we'll be doing that with the cam putting the top at dive now if you're following along with this series and you want to get notifications and I want to upload a video click on a little bell here next to subscribe there's a little bell there and you'll get a notification every time I upload a video thanks for stopping

by peace for [Music] [Applause]

Related Videos

14:22

Engine Building Part 3 Installing and De...

Pete's Garage

512,006 views

14:49

Jay's Tech Tips #47: Piston Ring Filing - ...

REALSTREETPERFORMANCE

198,541 views

11:37

Engine Building Part 1 - Installing the Cr...

Pete's Garage

147,927 views

13:42

4 Stroke Piston Rings From A to Z || Ident...

Brian D. Mobley

128,860 views

16:02

Engine Building Part 1: Blocks

Pete's Garage

1,692,914 views

8:09

Engine Building Part 4 - Installing the Oi...

Pete's Garage

219,695 views

13:40

End Gap Mistakes That Will RUIN Your Engine

Total Seal Piston Rings

473,869 views

13:05

Measuring For New Piston Rings | Chevy 350...

Yoshimoshi

36,776 views

12:09

Why Do Engines Need 3 Piston Rings? Explained

The Engineers Post

722,104 views

17:26

Your First Engine Job - Honing For Crossha...

Uncle Tony's Garage

156,141 views

14:38

How to install piston rings and not break ...

How 2 Wrench

966,543 views

29:41

Engine Building Part 3: Installing Cranksh...

Pete's Garage

1,016,677 views

14:36

How to Gap Piston Rings (very easy)

That Engine Guy

127,545 views

47:25

Engine Building Part 7: Installing Heads...

Pete's Garage

539,287 views

8:38

Installing Rings on the Piston

MAHLE Motorsports North America

282,935 views

20:28

Building a 14.0:1 High Compression 416" LS...

That Engine Guy

67,992 views

14:29

Piston Ring Gap Tips! (How much do you need?)

CUTTER'S PERFORMANCE

66,619 views

6:58

How to Clock Piston Rings: Gap Orientation...

Speedway Motors

148,697 views

12:37

SBC Piston Ring and Rod Orientation (For t...

CUTTER'S PERFORMANCE

306,212 views

24:59

Quick Cam degree

Myvintageiron7512

264,120 views