Making the Smell of Rain

527.41k views5047 WordsCopy TextShare

Chemiolis

Doing this project has been a goal of mine for many years and it finally happened (proud chemistry n...

Video Transcript:

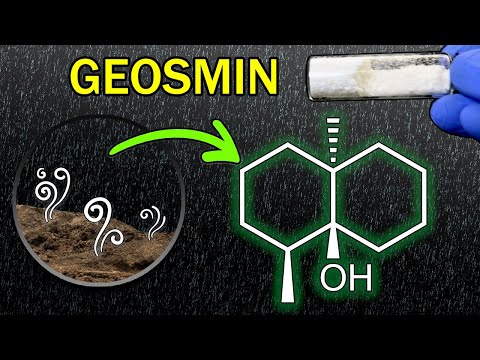

you know that strong earthy smell outside after it has rained especially on a warm day can I replicate that in a lap and make some kind of rain smelling fragrance that was the question I asked myself many years ago and now it is finally time to do it so I went online like any professional chemist would and ask Google what causes the smell of rain so the smell is called petracore and it seems like the molecule geosmin is the main contributor to the smell okay so geospin how do I make it it seems like this paper doesn't enhance your selective synthesis of deuterated lever to use men but I can just ignore the deuterated part and it seems pretty achievable so this is the order of the reactions the only thing is they start with this now how do I get that after searching around I found a 30 year old paper that makes it seem pretty achievable so that adds some extra steps but it starts simply from two methyl cycloaxenone now there's also one reagent that I tried to make before on my channel which is Ethel final Ketone since I am mad that it didn't work out I simply refused to buy it and I still want to make it myself so after gaining about a year of experience I found another method for which I have all the chemicals on hand and it seems to be pretty straightforward so why not so the first thing I will do is prepare ethyl vinyl Ketone so I set up a heating mantle and add a large flask and a stir bar I add 65 mils of hexanes as a solvent and then 66 mL of diethyl Ketone as the first reagent I then add 40 mL of ethylene glycol as a second reagent and 40 milligrams of pea toluene sulfonic acid as the Catalyst now that all of the reagents have been added I put a Dean Stark apparatus on top and fill it completely with hexanes until it overflows into the flask then on top of that I add a condenser now I start heating the mixture so that it begins to boil and leave it rotting until it's finished the boiling hexanes will carry over any water that is formed during the reaction they will condense together in the condenser and then fall back down into the reservoir since water does not mix with hexanes and has a higher density it will sink to the bottom of the reservoir and collect there so with the dean Stark apparatus we can continuously remove water from the mixture while also tracking how much water has formed since we know how much water should be formed theoretically we can use this to judge when the reaction is complete in the reaction the acid catalyzes the reaction between diato Ketone and ethylene glycol to form the ethylene glycolacetal of diethyl Ketone and water since the product can undergo the reverse reaction in the presence of water we have to continuously remove it by using the dean Stark apparatus otherwise the reaction will find its equilibrium and stay there and we would not get much of the product I'll leave it running for about 8 hours and when I come back we can see a lot of water has collected in the apparatus with the amount of reagents that I added the maximum amount of water that could have formed is 11. 25 milliliters we can see that the water level is sitting a bit above 10 mils and there are also some water droplets sticking in other places this pretty much confirms that the reaction was successful and that it is finished I now add 310 mL of ethylene glycol to dilute the mixture and take it slightly off heat to allow it to cool down to about 35 to 40c now I can immediately start a second reaction and there is no need to purify the product so I attach a dropping funnel to the flask and add in 100 grams of bromine that I quickly made myself I then opened the dropping funnel and dropwise added to the mixture while keeping the temperature around 40c I continuously check the temperature with an IR thermometer and added a cold water bath to keep it in check this should prevent any side reactions from happening in the reaction bottom bromine of the dibromine takes up the slightly acidic Alpha hydrogen to form hydrobromic acid while the other bromine attaches itself to the carbocation that has formed to then form the mono brominated product when the addition was complete the mixture was still orange which means that unreacted bromine is present so I set a flask in a heating mantle and heated it back to 40c to force the reaction to completion after a while the mixture is clear again which means that all the bromine has reacted and the reaction is finished so I removed the dropping funnel and stopped stirring we then see the mixture separate into two layers with the hexane and the product on top an ethylene glycol on the bottom I move it all to a separatory funnel and add more hex stains to take up the product I then extract the ethylene glygo layer three times more with hexanes when the extraction was finished I combined all of the extracts in a beaker I add a stir bar then 12. 5 grams of sodium carbonate This Will Destroy any remaining hydrobromic acid and maybe stick to any ethylene glycol that might be present I leave the mixture to stir for a bit and then filter it all through some cotton directly into a flask to remove all of the sodium carbonate when it is finished I remove the funnel and attach a short path to installation apparatus and now start heating and Distilling over all of the hexanes under a mild vacuum after a while no more hexanes was coming over and a clear liquid was left behind which should be mostly the mono brominated product I then swapped the receiving flask and increase Heating and then pull a strong vacuum to distill over the product the product starts distilling over at 41c at a pressure below 1 millibar since the vacuum gauge doesn't read between 0 and 1 millibar I can't know the exact pressure I assisted desolation with some light heating from a heat gun to make it go faster and after a while nothing more comes over and only a tiny bit of Cloudy liquid is left in the flask in the end I collected 108.

94 grams of the product as a clear liquid which is a yield of 83 this is very similar to the literature where they achieved a yield of 90 the liquid feels quite Hefty and it probably has a decently thick density the smell is surprisingly fruity when they loot its spells similar to pineapples but smelling it directly makes it more smell like glue anyhow the yield is quite good and with that I can move on to the next step so I set up a flask with a stir bar and a heating mantle and add 100 ml of methanol I then add 58 grams of potassium hydroxide and reflux it to make a solution containing potassium methoxide this reaction will be in equilibrium mainly influenced by the amount of water that is present I then add 290 mL of DMSO as a dilutant and solvent which causes the potassium hydroxide and methoxide to precipitate out I heat it to ADC and the solid dissolves again I then remove the condenser and replace it with a dropping funnel now into the dropping funnel I add in all of the mono brominated products a dropwise added to the flask while keeping the temperature around 80c in the reaction the methoxide ion is a very strong base it will take up a proton from the carbon adjacent to the one the bromine is attached to and for methanol this will cause the formation of a double bond which leads to bromine getting kicked off but the remaining potassium ion is there to save the bromine from being alone and together they form potassium bromide which precipitates out of solution I continue the reaction and I make sure that the temperature is correct by checking with a thermometer after a while all of the mono brominated product has been added and we are left with a dark liquid that has a bunch of suspended potassium bromide I then set the mixture up for short bath vacuum distillation to remove all of the methanol I then swapped the receiving flask and increase the heat to start distilling over a mixture of the vinyl product and the Amazon after a while it looks like no more product is coming over and it seems only pure DMSO is distilling over so I stopped the distillation now I have a mixture of the MSO and the final product so to remove the DMSO I can simply wash it out since it is water soluble but the product is not very water soluble so I add some 5 sodium chloride solution to the mixture and then move it all to a separatory funnel the sodium chloride in the solution helps to increase the polarity of the water and so it will dissolve less of the vinyl product the mixture now has two layers and on top is the final product I washed it a few more times with a five percent sodium chloride solution and afterward I was left with 50 grams of the vinyl product as a clear liquid which is a yield of 75 this is also a pretty decent yield since the literature had 86 percent this product unlike ethylphenyl Ketone is quite stable so it is good to store this product and only start making ethyl vinyl Ketone from it when it is needed the smell of this product is strong like turpentine or some kind of glue it is not very pleasant and kinda gives me a headache anyhow since I will be needing the ethyl vinyl keto now I can make it right away so I set up a flask with a stir bar and add in 55 mL of water I then add 0. 85 grams of pea toluene sulfonic acid and 25 mL of the final product I stopped with a flask and then leave it to stir for three hours at room temperature in the reaction we are converting the acetal group back into a ketone by hydrolysis with the help of the asset Catalyst this will produce the ethyl vinyl Ketone and also return the ethylene glycol that was used to make the acetyl after three hours I put a flask in an ice bath and then add 0. 3 grams of sodium bicarbonate to destroy the acid and then 11.

3 grams of sodium chloride this will increase the polarity and saturation of the water and kick out most of the ethyl vinyl Ketone that has dissolved into it I then move the mixture to a separatory funnel and extract it three times with ozylene in the literature they used P thymine to do the extraction but the closest thing I had was ozylene I'm not sure if they specifically selected P siamine to improve the distillation or if they are just ancient for old papers it can be hard to charge if they do something because it is necessary or simply just because it was normal or available at the time anyhow I combined all of the ozylene extracts in flask and set it in a heating mantle I add 80 milligrams of hydroquinone to the solution as a stabilizer which will scavenge radicals and help prevent ethyl vinyl Ketone from getting destroyed and then attach a fractionating column and a short path installation apparatus I pull a strong vacuum and heat the mixture lightly and with the help of a heat gun I start distilling out the ethyl vinyl Ketone since it's slightly volatile I set an ice bath under the receiving flask it did come over though it still took quite some time and effort to get it to come out despite it being relatively volatile in the end I collected enough Ethel final Ketone to start the teasmine synthesis it seems also some residual water had gone through and was sitting on the bottom but I will simply avoid taking this up when I'm going to be using it the smell of Ethel final Ketone is like a spicy sharp vegetable and it also stinks the nose a little anyhow now that I have ethyl final Ketone I can move on to the next step so I have some 2-methylcyclohexanone that I made in a previous video but that was like a year ago and in the meantime it has turned slightly yellow I will not use it like this so I'm going to redistill it so I add all of the dirty two methyl cyclohexanone to a flask and distill it over through a fractionated column under regular pressure when that is done all that is left in a flask is some yellow stuff I removed the first fraction from the distillate and also the last and I should now have 9. 19 grams of pure 2 methyl cyclohexanone which I will use right away so I set up a heating mantle and a flask with a stir bar so I will also need s levo Alpha methylbenzylamine which I bought a very long time ago since I always wanted to do this project and I stored it in the fridge this whole time and I finally get to open it if anyone is curious many chemicals that are considered dangerous coming this type of packaging but before I get to adding it I first add in 50 mL of toluene as a solvent I then add in all of the two methyl cyclohexanone that are redistilled and then 10. 5 mils of s lethal Alpha methyl benzylamine like earlier I attached a Dean Stark apparatus but this time I filled it with toluene I also insulated it with some aluminum foil so I just had a hard time coming through in the reaction the methylbenzylamine reacts with the two methyl cyclohexanone to form the corresponding amine product and water since the amine is also water sensitive we again use the dean Stark apparatus to remove it I leave it to react for a day and when I come back we see some water as collected in the apparatus in theory a maximum of 1.

48 mL of water can form during the reaction there are also some droplets sticking at the top so it seems that pretty much the same amount of water has formed so the reaction should be finished I then set the mixture up for short bath vacuum distillation to remove all of the toluene in the end I am left with yellow why is it always yellow why not just green now to this product I directly add 8. 1 mils of ethyl final Ketone and flush the flask with nitrogen I then leave it to stir for a day at room temperature this reaction is a type of stork reaction which is a micro addition where the nucleophile is an enamine the amine is an equilibrium with its enamine form the enamine form can react with the ethyl vinyl Ketone which is a great micro acceptor to produce the final product this happens in a stereo selective manner due to the presence of the bulky methylbentylamine and it will favor the r configuration I come back a day later and it looks the same I then add 62. 5 mils of methanol as a solvent and then 37.

5 mils of 10 acetic acid the addition of water and acetic acid will hydrolyze the product kicking off the methyl benzylamine and returning the Ketone to give the dye Ketone product I leave it to stir at room temperature for a few hours and after that it has become I then move it to a heating mantle and set it up for a short bath vacuum distillation to remove all of the methanol when that is done I dilute the mixture with 100 mL of water and move it all to a separatory funnel I extract it three times the diethyl either and then return the combined ether extracts to the separatory funnel I wash it once with 10 hydrochloric acid which will force the methyl benzylamine into the water phase by protonating it I then wash it once with water to wash out the acid and then once with brine to cut out most of the water I then take the ether layer and pull out any remaining Water by adding magnesium sulfate I then filter the mixture through some cotton to remove the magnesium sulfate again directly into a flask I then attach a short path distillation apparatus again and distill off all of the ether when all of it is gone a light yellow liquid is Left Behind which should contain the dye Ketone product I then add 90 ml of methanol as a solvent and a solution of 0. 46 grams of potassium hydroxide in methanol which will contain some potassium methoxide I attach a condenser and then heat it to a reflux and leave it for two hours in the reaction the base catalyzes the dye Ketone to cyclicize into the first cyclic product usually the previous edition of the vinyl Ketone which is now followed by an aldoor condensation into a fuse ring system would be referred to as a type of Robinson and Elation when I come back the mixture has turned even I removed the condenser and add 0. 5 mils of glacial acetic acids to neutralize it I attach a short path distillation apparatus again and remove all of the methanol under reduced pressure when all of the methanol is gone all that is left is a dirty yellow liquid I then add 90 mL of water to dissolve impurities and some diethyl ether to take up the product I move it all to a separatory funnel and extract the water face three times with either I combined all of The Ether extracts dried it with magnesium sulfate and then filtered it again I again remove all of The Ether and then start distilling over the product at first some lower boiling liquid is coming over which smells very similar to two methyl cyclohexanone so it's probably just residual to methyl cyclohexanone after a while that stops distilling over and I change the short path for another smaller one I then start distilling over the cyclic product with the help of a heat gun I squeeze out every last drop that I can and afterward I am left with only 1.

7 grams of the cyclic product as a clear oil I'm not sure which Step was so low yielding but unfortunately the yield turned out to be only 11. 6 percent well at least it's something so let's just continue and move on to the next paper I set up a flask with a stir bar and dissolve all of the cyclic product into 125 mL of DCM and transfer that to the flask I then at 1. 61 grams of sodium bicarbonate and set the flask in an ice bath I flush the flask with nitrogen and then slowly start adding in 2.

46 grams of M chloroparbenzoic acid while keeping it under nitrogen when everything was added I stopped with the flask and leave it to stir for two hours on ice and then for two days at room temperature this reaction is a typical pileshaft epoxidation where an alkene double bond reacts with a peroxy acid to form the corresponding epoxide the sodium bicarbonate was added to counteract the acidity of the perpendoic acid which could lead to side products after a while a white precipitate formed which is the insoluble sodium salt of M chlorobenzoic acid now I wash the reaction mixture two times with 100 ml of a one-to-one mixture of a saturated sodium thiosulfite solution and a saturated sodium bicarbonate solution I do it inside of the flask and decant the upper water layer since the solid has soaked up the DCM it can't be done inside a separatory funnel I watched it one time with some Brine and then add a bunch of sodium sulfate to hold on to any remaining water I shake it strongly and then filter it all through some cotton after 100 years it has all filtered through and that is still off all of the DCM with short path vacuum distillation when only a bit of the DCM is left I add 4 grams of sea light which will absorb the product and then continue distilling off all of the DCM when all of the DCM is gone only the sea light that contains the product is left now to purify the product I have to do column chromatography so I set up a column and add in 100 grams of spherical silica gel that I mixed with 20 diathl ether and hexanes I allow the silica to pack and then add a layer of sand on top I run the solvent level into the sand and then add all of the sea light with the product on top I add some sand to the flask to scrub loose any remaining sea light and add that on top as well since there were some air bubbles I tried to loosen them by tapping the column with a cork ring but I went a little too hard and the top layer became uneven though for this separation it doesn't matter too much since I'm only trying to remove the bottom half of the spots on the DLC I run the column by applying pressure with a pump and after that I collected fractions of varying sizes on the tlcs we see fractions 3 to 8 contain the upper half of the components and the other fractions only the lower half so I take fractions three to eight and combine them in a flask I then distill off all of the solvent and afterward I am left with a little bit of product that has a very sweet and floral smell now for the next reaction I dissolved the product in 20 ml of dry thf and then set it aside for a second I set up another flask in a heating mantle with a nitrogen line I then connect the condenser and add in 60 mL of dry thf and add in 1 gram of lithium aluminum hydride I heat the mixture to a reflux and attach a dropping funnel then to the dropping funnel I add the product thf mixture and drop eyes added to the flask I then leave it for 2 hours in the reaction lithium aluminum hydrides will transfer a hydride to the Ketone and epoxide causing both to be reduced to an alcohol and give the corresponding dial product with that it's finished I add 30 ml of a saturated sodium sulfide solution to the now empty dropping funnel and add that gradually to the flask This Will Destroy any remaining lithium aluminum hydride as well as protonate the product the sodium sulfide also helps the thf and water separate by salting out I then add 5 mils of 10 hydrochloric acid which will make sure that all the product has protonated and also neutralize the solution by reacting with formed lithium hydroxide I then move it all to a separatory funnel extract it with ether and wash it with brine I take the combined ether extracts and try it with sodium sulfate I then filter it all through some cotton and do the exact same as in the previous step and the seal over part of The Ether and then add in 3 grams of sea light I run the column again in the same manner but this time the separation is a lot easier the product is a lower spot on the DLC it took suspiciously long for it all to elude off the column which is a thing when the solubility of the product is low in the oven but it wasn't the problem since it was the last spot on the TLC so nothing else could come through anyway I combined all the fractions containing the product and still have all of the solvent again and only very little is left a white solid already precipitates out of solution after a while it is completely dry and only the product is left as a white solid now to start the last step I dissolve it in 160 ml of chloroform and add 3. 2 mL of pyridine I then add 8 grams of pea toywine sulfonyl chloride and flush the flask with nitrogen I stopped with a flask and then leave it to react for 4 days at room temperature in the reaction the Pea toy windsorphalochloride will react with one alcohol group to form the corresponding tosulate and hydrochloric acid the torsolute is a good leaving group and can therefore be used to remove the alcohol the pyridine in the reaction mixture will take up the hydrochloric acid to form pyridine hydrochloride when I come back it is still a clear liquid and I replace the stopper with a dropping funnel I then add in a suspension of 0.

Related Videos

36:22

Making The Sweetest Compound Known (Lugdun...

Chemiolis

4,097 views

33:33

I Made Cubane First

Chemiolis

311,623 views

30:52

Making Cat Attractant (Nepetalactone)

Chemiolis

175,298 views

26:59

Recreating the smell of rain (Petrichor) w...

Sam Macer

28,922 views

26:36

THE STRONGEST ACID IN THE WORLD Fluoroanti...

ChemicalForce

7,102,370 views

28:33

Making and Tasting Government Banned Sweet...

Chemiolis

235,103 views

26:36

Making and Testing The ANTI-SPICY Molecule...

Chemiolis

148,697 views

11:43

Extracting Safrole to Make Government-Bann...

LabCoatz

1,968,261 views

15:18

Making cadaverine

NileRed

930,984 views

14:29

Can You Trust NileRed?

Chemiolis

536,569 views

14:05

Why is All Life Carbon Based, Not Silicon?...

Arvin Ash

2,569,312 views

15:41

Making Cubane (without handles)

Chemiolis

95,259 views

13:27

Making and Tasting the COLDEST Substance K...

Chemiolis

119,771 views

34:12

Extracting Neodymium from Harddrive Magnets

Extractions&Ire

436,990 views

30:48

Turning vanilla flavoring into dopamine!

Pyrotechnical

587,790 views

16:19

What is Fool's Gold?

NileRed

5,288,985 views

7:05

LSD Synthesis in 7 Steps (Educational) | L...

Total Synthesis

578,609 views

27:15

The Most Misunderstood Concept in Physics

Veritasium

14,572,568 views

44:11

What Do Vitamins Actually Do? (Vitamin Lore)

That Chemist

1,004,811 views

12:35

Nobel Laureate Claims: What the James Webb...

TheSimplySpace

30,966 views