SAP EWM Fundamentals - High Level Inbound Process Overview for Beginners / SAP EWM

12.71k views1853 WordsCopy TextShare

KnowYourEWM

SAP EWM Fundamentals - Inbound Process Overview for Beginners

our BEST RATED course on UDEMY https:...

Video Transcript:

[Music] [Music] hello everyone my name is Chris and I have the honor to guide you through the ewm process today the start of slow our first sequence of getting in touch with the extended warehouse management is an overview over the so-called inbound delivery you just have to keep in mind that I'm going to show you the most basic process which every ewm implementation boils down to you might have a lot of optional steps in your own warehouse for sure but the basic principles apply to every Warehouse so without further Ado let's jump right into to

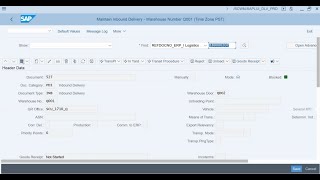

it [Music] [Music] [Music] [Music] [Music] [Music] [Music] what [Music] as you can see I already opened the ewm inbound delivery monitor the inbound delivery monitor offers you an overview over all the data being transferred to the ewm system as well as functions to repack delivery items create Warehouse tasks and post the goods receip you can reach this monitor function via the easy access menu or because I prefer to have the basic ewm programs in mind with the following transaction code now let's have a look at what Linder received on her Workstation first of all you

can see two separated views in the transaction well actually there's three but when you open your first inbound delivery in your own ewm system you will find out that the second and third screen are basically the same so to keep it easy in the beginning we are just going to focus on the header and item view the upper view contains the inbound delivery Header information this information BAS basically shows you what kind of delivery you have in front of yourself maybe it's a replenishment delivery or maybe it's a customers return as you can see there's

a lot of different delivery types which you can all use and customize according to your warehouse's needs in the middle part of the screen we see the different items being supplied to the warehouse in this specific delivery we now see that Linda has received a whole lot of sungasses today and one of those delivery items is our nice handbag let's have a look at this one in the item tab you can see all the basic information concerning this product like for example the product number and the goods Reed status of the item in this example

Linda already posted some of those Handbags and therefore the goods received status is partially completed that means that there's still at least one piece we can post the goods received for and as soon as we post the goods received for the remaining quantity you will see that the status is going to change but before we do that let's find out what other information the inbound delivery provides on the dates and times tab we can see when the inbound delivery was created in the ewm system and when we made the first action with it in this

example we can see the delivery should have been arriving in the warehouse at the end of March but the actual arrival happened on April 2nd now let's have a look at the partners tab here we also can answer some of Linda's questions the delivery items are obviously supplied by our partner the fashion production company and got delivered to us by the international Parcel Service the reference document tab basically shows us how the corresponding delivery in our Erp or as fana system is called this is very helpful if we have to communicate with other departments in

our company that only work with the Erp delivery number at this point I want to give you a note that with Asana as the main reference system in the future it is possible that ewm and Erp delivery numbers are the same the next two tabs we are going to skip because they are basically self-explanatory and let's go right to the handling unit tab here we can see that only one handling unit is left for Linda to work on the tab contains the basic handling unit header in information like the hu number the packaging material and

lot of other informations more on that we are going to see later in this episode and last but not least the last important T we are going to focus on today are the so-called ppf actions what exactly those actions are I'm going to explain to you in another training course right now you just have to know that those actions displayed here take care of sending the information of lindus goods receipt postings to the Erp system because every change of stock also needs to be executed there too in order to keep both systems in sync and

the goods receipt process generally speaking creates stock in the warehouse now we have had a lot of information to show to you guys and I also hope we could help Linda to answer all of her questions let's have a look at what she's up to with the inbound delivery [Music] [Music] [Music] [Music] [Music] [Music] H um [Music] well no problem Tom of course we can show that again but please try to focus and pay attention next time so let's see we saw Linda packing the nice handbag from one parcel into another one but before we

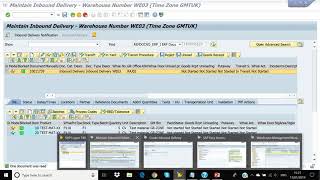

are going to do that let's have a look at the handling unit itself so let's switch to the handling unit view in the inbound delivery Monitor and check out the part parcel in the packing view we now see how our parcel is packed since we only have one handling unit left of course only one is shown on the hierarchy by expanding the few we can have a look at the handling unit items wow Linda has been really quick with repacking and goods Reed but fortunately we have one handling unit left we can pack now after

this short handling unit overview let's get back to the inbound delivery in order to pack or in this case let's say repack our nice handbag from one parcel into another parcel we have to open the menu path select the inbound delivery node select the follow on functions and then let's go right to the PC node you might wonder why this message popup appears right now well the message we see right now appears every time the delivery has already been partially posted Goods received now the ewm switches to the packing view basically we now see the

same view as before but this time we can actually change stuff the first view was just for displaying purposes now before we actually execute the packing process let me explain to you in a second why such a repacking process could be helpful first of all the packing process is of course an optional step we do not need to have a packed inbound delivery in order to post the goods received but from our experience most warehouses operate with some kind of handling unit to transport goods from the goods receipt Zone to the actual putaway of course

since our example is already packed we would not have to repack it but let's just assume you have some sort of conveyor system in your Warehouse that only allows certain sizes of handling units to be transported and the vendor's boxes do not fit that size or maybe you do not have a cotic storage in your warehouse but the storage where the different types of products are stored in different storage areas with a certain distance between them in this scenario it would be helpful for a more efficient putaway process to build up handling units in the

goods received Zone that only con contain items that are stored in one specific area of the warehouse let me explain that with a practical example let's suppose we pack one handling unit with all the sunglasses and another handling unit with all the handbags the putaway process can now be done much quicker if the warehouse workers do not have to walk through the whole Warehouse to confirm the put away just because we didn't repack during the goods receipt process now that you know why we want a repacking process to be executed during or after the goods

received let me show you how Linda did that at first we have to create a handling unit this handling unit is the so-called destination handling unit for our packing process therefore we have to enter a so-called packaging material this packaging material tells the ew M what kind of handling unit we want to create whether it's a carton or a pallet or maybe some other sort of compartment the second input Linda made in the ewm system was the handling unit number this number identifies the handling unit itself if we now click on the execute button you

can see that the ewm creates the handling unit and inserts it into the packing view right now we have two handling units in our inbound delivery the one we got delivered and the new handling unit we just created the easiest approach to repack is that we simply drag and drop the item we want to pack and as we see the ewm packed our nice handbag into the newly created handling unit the next step is to save our onscreen action if you do that the system is going to show us a message that says empty handling

units will not be saved the ewm is then going to delete the empty handling unit but why is that empty handling units can never be part of any kind of delivery whether it's an inbound or an outbound delivery it's always the stock that is part of a delivery and only if this stock is packed into a handling unit the hu becomes part of the delivery so let's confirm the message since we know that our source handling unit got empty during the packing process and basically that's it we successfully repacked stock in an inbound delivery now

let's head back to the inbound delivery monitor the last step Linder performs now is the actual Goods received cuz everything we did until now was basically just repacking the nice handbag from one handling unit to another so let's do it let's post it the ewm confirms that a good receipt posting has been performed since our nice handbag was the last item to be posted in this particular inbound delivery we can now see that the overall Goods receipt status is now completed yes guys we successfully did it we repacked our inbound delivery and posted the goods

received now as the final step let us have a look if we inform the Erp system about our posting as well so let's check check out the ppf actions tab and look for our message and here we go there it is so Tom I hope you paid attention this time [Music]

Related Videos

5:59

SAP EWM Fundamentals - High Level Stock Av...

KnowYourEWM

2,355 views

1:10:37

SAP EWM for beginners, Functionalities of ...

ADVANTEX IN

48,008 views

32:19

SAP WM Introduction to Warehouse Structure...

SAP Extended Warehouse Management

99,253 views

19:27

SAP EWM Overview for Beginners

Jh Softech

559 views

16:43

SAP EWM Training - Stock Tables in SAP EWM...

KnowYourEWM

4,583 views

1:22:10

SAP EWM on HANA Inbound Process 1

TechBrainz Consulting

3,420 views

22:00

Understand SAP EWM - Warehouse Order Creat...

WMexperts.online: Intralogistics & SAP EWM

12,920 views

44:19

SAP EWM & S/4 HANA Chapter 1.1: Key Concep...

Tim Heb (SAP Trainers Group)

54,033 views

19:02

The difference between EWM and WM and what...

Steven Chittenden

13,521 views

8:05

What is SAP EWM Explained | Introduction t...

Learn with Whiteboard

46,404 views

13:40

SAP EWM Training - BADI Implementation in ...

KnowYourEWM

8,510 views

30:00

SAP EWM- Putaway Strategies Full Overview ...

Studyuuu SAP MM / EWM

2,702 views

1:11:58

SAP EWM Warehouse Structure & Master Dat...

TechBrainz Consulting

11,704 views

16:05

SAP EWM Training - Warehouse Task & Wareho...

KnowYourEWM

3,456 views

9:38

SAP EWM Inbound Demo by Rajaram

Rajaram Govindan

14,008 views

15:43

How to learn SAP EWM? How to start with SA...

WMexperts.online: Intralogistics & SAP EWM

1,234 views

59:12

EWM Webinar Series_ Part 1_EWM_Inbound Proces

LogiStarSolutions

33,402 views

3:01:23

SAP Extended Warehouse Management Overview...

Expertsoft SAP India Trainings

2,090 views

28:16

Process Oriented Storage Control For INBOUND

Krypt Inc - SAP Consulting Services

24,820 views

56:59

SAP EWM Tutorials for Beginners | SAP ECC ...

Online Coaching

22,423 views