How Japan's Maglev Train Works

2.62M views2694 WordsCopy TextShare

Real Engineering

Sign up to Brilliant using my link and get a 30 day free trial AND 20% off your an annual subscripti...

Video Transcript:

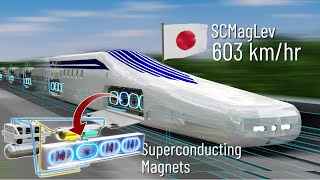

Buried here, deep in a Japanese mountain pass, is one of the world's rarest technologies. A 43-kilometer-long magnetic levitation train track. Which will eventually become part of the world's first inter-city Maglev train, connecting Tokyo and Osaka.

With the power of superconducting magnets, these trains hover a mere 10 centimeters above their track, while pummeling along at a mind-boggling speed of 500 kilometers per hour. With no physical contact required with the track, they can operate in any weather conditions and have lower maintenance costs due to reduced friction and fewer moving parts. Despite the advantages of Maglev trains over traditional high-speed trains, The only commercial high-speed Maglev line currently in operation is just 30 kilometers long.

Connecting Shanghai Airport to it’s city. A journey the train makes in only 8 minutes, but a track this short largely defeats the advantage of high speed maglev, by the time the train gets up to speed, it needs to slow down again. A 30 kilometer journey in 8 minutes actually equates to an average speed of 225 kilometers per hour, slower than the top speed of conventional high speed rail.

The planned future network of high-speed maglev tracks, just 400 kilometers long, and it pales in comparison to the extensive network of 60,000km of regular high-speed train tracks already in place around the world, with an additional 50,000km under construction. Why is this gap so large? Let's delve deeper into how Maglev trains work and explore the reasons behind their restricted deployment.

We have two primary methods of levitating a train. We can pull the train up using attractive forces or push the train upward using repulsive forces. The pulling approach involves a combination of a magnetic iron rail and an electromagnet that uses attractive forces to raise the body of the train.

This is an active system where the gap between the rail and the magnet is crucial as the strength of the attractive force decreases with the square of the distance. Meaning, the train needs active controls and feedback loops ensure that these gaps stay between 8 and 12 mm. If the train begins to drop, the magnetic force holding it up will quickly weaken, causing it to fall even further.

It’s an unstable configuration. These types of trains are referred to as Electromagnetic Suspension trains. This is the system the 30 kilometer line in Shanghai uses.

[1][REF_00] Japan opted to use a different system, with a more significant gap of 10 centimeters between the track and train. 8 times greater than the gap for electromagnetic suspension, while also providing a passively stable method of levitation. A vital property to have in the earthquake prone region.

[2] In this approach, magnets onboard the train interact with passive coils on the track. As the train moves over these coils, they experience a changing magnetic field, which generates the opposing field that lifts the train upward. If the train is stationary on top of the coils, there is no change in the magnetic field.

So this dynamic system only works when the train is already going fast. The trains have wheels that drop down when the train is slowing down, but flip into the carriage when they reach 100 km/h. [1] In order to achieve a stable position on the track, the north and south poles are arranged vertically on the sides of the track.

The magnets are formed from coils of wire, arranged in a figure 8 pattern. A south pole points upwards on one side, while the north pole points up on the other. If the train were to drop slightly or move sideways, the magnets on the train induce currents on the opposite coils, generating a stronger magnetic field, which pushes the train back to the midpoint of the figure 8 shapes.

[3] This dynamic system is forgiving, with the 10 centimeter gaps between the track and the train naturally maintained with no need for complex control inputs. [1] However, the Japanese Maglev train, called L0, will be the first of its kind. These trains, known as SCmaglevs, need superconducting coils to generate the extremely powerful permanent magnetic field on the train.

These are the coils that induce the changing magnetic field and allow the train to levitate in a stable configuration. These coils, located on each side of the carriage, must be maintained below their critical temperature to ensure their current flows without resistance. The niobium-titanium coils are cooled using liquid helium and placed inside a container that is cooled by liquid nitrogen.

The coils are cooled using a Pulse Tube Refrigerator [4]. Which uses sound waves to cool the helium. The same type of refrigeration cycle that the James Webb telescope is using to keep its infrared sensors cold enough to detect even the faintest infrared heat radiation from the distant past.

A sound wave is just a pressure wave and pressure and temperature are directly proportional. Higher pressure will cause higher temperature. We can take advantage of this by creating a standing wave, where the peaks and troughs of the wave are stationary.

We can do this in a closed tube where the resonant frequency of the tube is determined by the tube's length. Here the sound wave will bounce off the closed end and create a region of compression and high pressure, and therefore high temperature. We can now place a stack that spans this hot region at the end of the tube to the cold region at the centre.

Now if we place a heat exchangeron either end of the stack, we can now transfer the heat to a radiator and the cold side will conduct heat away from the superconducting coils. Keeping them cold. [REF] [5] There are eight of these coils per car, with four on each side.

However, having a magnetic field strength of this magnitude right next to passengers, and traveling by at half the speed of sound, could cause some serious problems. Ferrous objects aren’t allowed anywhere near MRI machines. The engineers needed to find a way to ensure the magnetic field did not extend into the passenger cabins, or far away from the train.

We can’t block magnetic fields, but we can redirect them, in the same way we can conduct electricity to where we want it to go using copper wires. Where we measure the ease of passage for an electric current with resistance, we measure the ease of passage for a magnetic field with reluctance. Where copper has a low resistance, Iron has a low reluctance.

We can use electric steel shielding to divert the magnetic field away from the cabin and stations. Electric steel contains 3% silicon and is post-processed to produce large crystal grains aligned in a specific direction, which is controlled by a cold rolling process. The grain oriented electrical steel can carry about 30% more magnetic flux in this direction, allowing engineers to direct the magnetic flux in the desired direction.

[6] However, this shield is heavy, so we want to use as little of it as possible. Luckily, we can also tailor the magnetic field shape through careful design of the magnets themselves. If we placed two parallel magnets like this, north poles aligned horizontally, the magnetic flux lines would run parallel to the magnets and be densers between the magnets.

However, if we flip one of them, the magnetic flux lines connect up and create a kind of bubble in the between them. The magnetic field will be weaker in this location. This is how we arrange the coils on either side of the cabin.

There are 4 sets of coils on each side. So we also need to flip the magnets so the north and south poles face each other. This creates a low magnetic field bubble through the corridors.

[7] With the use of shielding, the field strength is reduced to only 0. 5mT, almost equivalent to Earth's the magnetic field. [7] Of course, near the magnets the field's strength is unavoidably high, and this prevents us from using certain materials in these areas.

The tracks for example need to be constructed from low-magnetic steel, or fibre reinforced composites. [8] But how does a levitating train propel itself if it’s not touching the ground? For conventional rail we just apply a torque to the wheels that will push off against the ground.

Wheels are actually a bit of a middleman in the development of torque. Many trains use electric motors to turn their wheels. The electric motors use electromagnetic force to turn a shaft.

What if we could take the same motor and unwrap it. This is called a linear motor. Where alternating coils attract and repel the train with precise timing.

[2] To brake the trains can use this system in reverse, this is regenerative braking. Since electrodynamic systems don’t work at low speed, they also have brakes for their wheels. The trains also feature an air brake that can slow the train down very effectively at top speeds.

There is one other challenge when dealing with contactless trains, how do they get electricity? For lower-speed Maglev systems they use a low friction third rail, common in metro systems, to bring electricity to the trains. [REF][2] But as speeds get higher this isn't practical [REF][REF_00] as it defeats the purpose of reducing friction from the rails.

Some early versions of the Japanese style electrodynamic system actually had a gas turbine onboard to provide power. But it now uses a linear induction coil to collect power from the changing magnetic field from the guiding coils. [REF][REF] [9].

This does create a magnetic drag force, but it’s more effective than carrying a large generator on board. The Japanese Line is set to be the first long-distance high-speed Maglev train. Its first phase, covering 285 km, will connect Tokyo to Nagoya and is scheduled to open by 2027.

The second phase, which will complete the remaining 438 km to Osaka, is expected to be completed a decade later. So why is Japan pursuing this futuristic technology? Japan has long been at the forefront of train technology.

After opening their Tokyo to Osaka Shinkansen line in 1964, the world's first high speed train, they immediately began exploring ways to reduce the 4 journey to under 1 hour. Starting in the 1970s, Japan Airways and the Japanese Central Rail Station constructed a 7km testing track here in. Miyazaki They began with prototypes of trains that could reach speeds of 60 km/h in 1972, and by 1995, they had developed trains capable of reaching up to 411 km/h.

As the Miyazaki test track became too short, the Yamanashi test track began construction in 1990. This 20km test track was conveniently located between the cities of Tokyo and Nagoya, along the route of the upcoming new Maglev line. Here, they transformed the design from a prototype to a fully functional train capable of carrying 700 passengers in 12 cars at speeds of 500 km/h.

But, high-speed Maglev trains are more than just a science experiment. They are an efficient and super fast way to move people. But, building these trains is more than just an engineering challenge, they are also an economic challenge where they have to compete against cars, planes, and other types of trains.

Whenever Maglevs are brought up in the US, the idea of traveling between New York and LA in 7 hours is often used as a statement of its potential. It’s the very first line on the US Department of Energy's own website. But a track of this length makes little economic sense.

[10] If we plot the travel time for trains, planes, and cars between say San Francisco and LA. Two large population centers within a reasonable driving distance, this is what it looks like. Trains are outright the best option.

Even though planes are faster, airports are usually located far outside the city, and security wait times increase the length of the journey. A high speed train will save passengers time, and in turn make an economy more productive. A reduction of travel time of 2 hours for 900 passengers equates to 1800 hours.

Equivalent to 75 days. Faster trains simply extend the range at which trains are competitive to airlines. Large cities between 200 and 800 kilometers apart are perfect contenders for high speed rail.

DC to New York in just 60 minutes. This map shows the potential economically viable high speed rail connections in the US. [11] Unfortunately, as it stands, the US is not investing much in high speed rail, and Maglev systems are even harder to build.

They require completely new tracks that require electromagnetic coils along the entire length and specialized materials that are not affected by the incredibly strong magnetic fields passing by them at 500 kilometers per hour. The Japanese line that connects Tokyo to Nagoya recently had a price increase to 13. 7 billion dollars.

Maglevs are between 10 and 50 times more expensive than high speed rail. The incredibly successful French high speed rail, the TGV built in the 80s and 90s cost 2 million dollars per kilometer [12]. The first stage of the Japanese line is set to cost 77 million dollars per km [1] Even when compared to the same route from Tokyo to Osaka via High-speed rail, the maglev system will cost 11.

3 times more per kilometer. That is a large price to pay to reduce the travel time by 1 hour. The Tokyo-Nagoya line is taking a more direct route through mountainous terrain, a staggering 86% of the track would be underground.

[13] Tunneling over 200 km significantly increases costs. Interestingly, this also leads to increased operational expenses. When the train travels in the open air at speeds of 500 km/h, the unobstructed air simply moves aside.

However, when traveling through a tunnel, the air has no escape route, this creates additional drag which in turn increases the force required to propel the train forward. [14] The energy usage of the new line will 30% higher compared to the existing Tokyo-Osaka line . [14] But that’s still vastly better than flying .

[15] For now, I don't see Maglev technology being used beyond some special projects like this. The radical increase in costs simply do not justify the increases in top speed over high speed rail. And it’s beyond imagination for the US, we are struggling to get regular rail service even in places uniquely suited to it like the Texas triangle.

4 high population cities located in a triangle, with only the hellscape of interstate highways connecting them. With the recent speculation about the potential of room temperature superconductors, a technology that would make maglev trains vastly easier to build, interest online in superconductor technologies is higher than ever. But a lot of it is unintuitive, and actually understanding how magnetic fields work is a fantastic tool in an engineer's arsenal.

So many of our most important technologies depend on this physical phenomenon. But, you don't have to pay for a whole university level course to understand the fundamentals. There's a free way you can learn about magnetism and electricity, with this fantastic course on Brilliant.

You can find this and tons of other courses on Brilliant, including one of their new courses “Predicting with Probability” Understanding probability and applying it to everyday situations is a great career tool, but also just an everyday common sense tool to help you navigate daily decisions. I highly recommend taking this course. Brilliant makes learning easy with fun, interactive courses that really succeed in getting you that dopamine rush as they test your knowledge along the way.

They have a fantastic mobile app so you can learn on the go too. . Brilliant has thousands of other lessons too.

AI, data science, neural networks and even our very own partnered Real Engineering course. You can get access to that course right now, and all of Brilliant's other curated interactive courses, by going to brilliant. org/RealEngineering or by clicking the link in the description.

Related Videos

30:10

The Insane Engineering of Orbit

Real Engineering

1,990,676 views

15:11

How Tesla Reinvented The Electric Motor

The Tesla Space

415,378 views

28:11

Riding the Japan's Fastest Bullet Train l ...

Experience JAPAN

19,484,352 views

15:57

Why French Trains Are The Fastest

Mustard

4,116,320 views

20:36

It's Happening - China Launches World's Fi...

Dr Ben Miles

1,690,330 views

8:33

The Self Balancing Monorail

Primal Space

9,079,230 views

19:46

Shinkansen: The World's Greatest High Spee...

RMTransit

399,493 views

15:53

Why Railroads Don't Need Expansion Joints

Practical Engineering

3,779,884 views

20:25

Biggest Megaprojects Under Construction in...

MegaBuilds

2,035,216 views

29:28

The Insane Engineering of the GEnX

Real Engineering

5,000,868 views

19:54

The Insane Engineering of the Parker Solar...

Real Engineering

3,697,644 views

12:20

How Australia Ships One Million Tons of Ir...

Aaron Witt

239,646 views

9:53

I rode the world's fastest train.

Tom Scott

6,073,272 views

11:34

The Fastest train ever built | The complet...

Sabins Civil Engineering

50,413,808 views

50:38

Megastructures: Building the Burj Al Arab ...

Banijay Science

4,126,078 views

27:26

The Insane Engineering of Re-Entry

Real Engineering

2,643,158 views

15:18

Building a SPEED Hyperloop

ProjectAir

1,532,846 views

51:34

Mechanical Batteries: The Future of Energy...

Free Documentary - Engineering

734,061 views

22:15

What's inside the Titanic?

Jared Owen

15,085,996 views

16:31

Most Useless Megaprojects in the World

MegaBuilds

49,299,998 views