How Arenas Transform Overnight

1.27M views2647 WordsCopy TextShare

Wendover Productions

Get Nebula using my link for 40% off an annual subscription: https://go.nebula.tv/wendover

Youtube:...

Video Transcript:

At 9:31 pm, the buzzer sounds, and the Chicago Blackhawks November 6th game against the Detroit Red Wings ends with a 4-1 loss. Less than twenty-two hours later, the Chicago Bulls game against the Minnesota Timberwolves begins, so within seconds the process of converting United Center’s floor from a hockey rink to a basketball court begins. First up is the broadcast crew, who quickly remove the remotely-operated cameras mounted on the glass.

Simultaneously, others roll up the rubber matts that cover the ground through the Zamboni tunnel so that ice crews and others on skates can walk around safely. Waiting behind them is the conversion crew—50 odd people, some full-time United Center employees, but most part-timers that come in after their regular jobs. Much of the crew waits by with the glass carts, which roll through the Zamboni tunnel as soon as it’s clear.

These carts are color-coded—red corresponds to the east glass, black for the west side, and white for the glass surrounding the benches in the center. Removing the glass is as simple as applying a suction cup, pulling upward, and grabbing the connector between each pane. The process moves fast—it takes just a few seconds per piece and, if anything, it's limited by how fast the crews can put the pieces away in the cart.

While this occurs, cleaning crews move through the sections of seats on the two far ends of the rink. These areas will entirely transform over the coming hours, so their cleaning is prioritized over the rest of the arena so that work can begin. And they specifically start on the west side since they’ll soon need a forklift, and the forklift can’t currently access the rink—the slope on the Zamboni tunnel is too steep, so they need to remove the seats that are currently covering the corner tunnel.

In addition to cleaning, others work on other small details to prep these seats for conversion—removing cabling, railings, and other small elements. Within just 25 minutes of the buzzer going off, as the final few fans are still in the arena, the last pieces of glass come down. Up until this point in the process, the crews have taken advantage of the coarse ice created through twenty-minutes of third-period professional hockey to provide traction as they work, but with the next stage of the process involving covering the ice, it’s now time for the Zamboni to come out and resurface it.

After all, the ice is always there—from pre-season through playoffs, no matter if there’s a basketball game or a concert, courts, stages, whatever is always built on top of the ice, as unlike essentially every other element needed for any United Center event, laying down the ice is a time-consuming process involving days of careful layering and methodical placement of lines, logos, and advertisements. It’s just not practical to lay down new ice for each game. And maintaining NHL-quality ice is also no easy feat, so as much as resurfacing the ice immediately is about prepping it for its next use, it’s also about ensuring that it stays high-quality even as an NBA game happens on top of it.

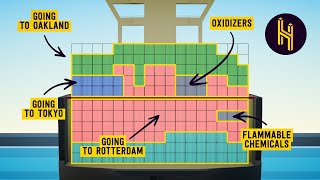

As the Zamboni does its work, part of the crew gets a brief break, but others continue work on the seating. This is one of the more complex parts of the process as the entire geometry of the playing area changes from hockey to basketball. An NBA court is less than half as long and almost half as wide as an NHL rink, meaning there’s plenty more room for seating.

In fact, all-in-all, 1,200 additional seats are installed during the conversion. The main difference is that seating extends closer to the playing surface, far past the hockey boards, but there are also other, subtler differences. In rink-mode, the Zamboni needs access, which requires having a large tunnel on one end.

In addition, players access changes between sports—with hockey, tunnels extend directly to the benches on one side of the arena, whereas in basketball there’s access via tunnels on all four corners, both for players and for those sitting in courtside seats. So that’s all to say, essentially the entire seating configuration near the floor changes between hockey and basketball. To achieve this in a matter of hours, the area’s seating sits on telescopic platforms.

The individual seats fold down flat, then section by section retract automatically. Once in their compact state, crews use a lifting platform to move them away from the wall—these essentially operate like a hovercraft, shooting air at the ground to reduce the effective weight of these massive seating sections so that the workers can push them around with simply their own strength. This side, with seating extending further down, is for hockey, whereas the side closer to the wall is for basketball as in the basketball configuration these seating sections only go down as far as to the top of the boards, rather than the bottom of the boards, to allow for more seating past the boards given the smaller court size.

For now, the workers flip the seating sections around so that the basketball side now faces the rink. As the Zamboni finishes up, a few other assorted off-rink activities occur—a couple people work to remove the corner sections of boards, as these are where the access tunnels will eventually be; a few others mop the floor previously covered by the telescopic seating; while one person presses the button to automatically retract the netting used to catch stray pucks. Additionally, others go and stage the next round of materials.

During hockey games, all the basketball components are stored in one large room underneath one of the long sides of the arena. The room is always organized the exact same way so that each cart is accessible when it’s needed—the glass carts, used first, are closest to the door, whereas the pieces of the actual basketball court, needed last, are furthest. With the Zamboni now done, crews bring out risers; some small seating sections; and rubber flooring.

One crew gets to work converting the benches where hockey players sit. They start with filling in the bench access tunnels with platforms, then affixing seating on top of them. Each tunnel takes up the space of sixteen seats, so considering how close the seats are to the action, filling these in adds up to thousands of dollars of additional revenue.

There’s also space within what was the benches, so the crews also place risers and seats within them. As this goes on, others quickly work to cover the rink in 530 different pieces of insulated plywood flooring. Most of this is fairly straightforward—equally-sized rectangles that fit together easily.

Where it gets tricky is towards the corners. To account for the curve, each piece is cut for its precise spot, and therefore placing any of the 530 pieces incorrectly will throw off the whole process. The last piece is the trickiest—on this night, it refuses to easily slot in, requiring the crew to remove some pieces and rework the placement as the rest of the crew watches on, waiting to be able to get to the next step in the conversion.

But once in, to lock the flooring in place, assuring it doesn’t slip even a bit, small spacers are hammered in around the edges. Now, this point in the process is where the next steps sometimes diverge. While NHL hockey and NBA basketball represent the core of United Center’s programming, the arena also hosts concerts, comedy shows, even the Democratic National Convention.

Most comedy shows and certain concerts use United Center’s in-house setup—using these materials, they’re able to set up a variety of simple configurations. Larger concerts from bigger acts, though, typically bring their own staging, so the United Center conversion crew gets the rink converted to this point, then the tour’s staff takes it from there. This can lead to some long nights.

Not only do concerts last longer, but the load-out of the tour’s equipment often takes two to four hours before the in-house crew can even start their conversion. And the timeline of when a rink conversion needs to be done by isn’t the start of the next game, it’s actually around 10:00 AM when the visiting team is allowed to use the ice for practice. So this leads to some long-hours and late nights for the crew, especially when the schedule leads to back to back to back conversions.

Things get even more complicated in playoff season as there’s often no knowing whether a rink or court is going to be needed for a game until the previous game finishes. And there are even some slight variations to the rink and court setups that they need to pay attention to. When an NHL game is broadcast nationally, for example, the broadcaster brings in additional cameras, and also setup an additional broadcasting position rinkside, which is why this glass sits here on the glass cart on this particular night—it was taken out since it was a national broadcast night.

But this November conversion was, at least relatively, simple—the rink to court transformation the crew is most used to. Next in the process is measuring—they use tapes and chalk to mark out where the corner of the court should go. Considering it’s far smaller than the rink, getting its location right is important to ensure the geometry of the seating that will surround it works too.

Then the court comes out. Unlike the rest of the materials, the court itself is stored in a standalone, temperature-controlled room. After all, it’s the most crucial, hardest-to-replace element of the basketball setup, and there’s only one of them.

Each piece is the same size, but it still must be assembled in an exact order due to the lines, logos, and advertisements painted on top, so they’re each individually numbered. Part of the crew lays out each piece in roughly the right place, while others follow behind and deal with the precise placement, using a mallet to align the pieces as tightly as possible. And precision is key—any slight misalignment with the first pieces will compound the further they go on.

A gap between flooring pieces is unacceptable for NBA play, so if that happens they’ll have to go back and re-do their work. While this goes on, work continues on the seating. Now rotated, the telescopic seating is extended out again, then these pieces of rubber are placed in between each section so that there’s no gap.

Unlike when in hockey mode, the front of these seating sections now only go as low as the top of the boards, rather than the bottom. The arena uses this additional height, and the shorter length of the basketball court, to fit in additional rows of seating. Small sections are rolled out by hand to fit in the corners, but the bulk of these rows is brought out by forklift and carefully placed in front of the boards.

Once all in place, these seating units too will extend out automatically all the way down to court level. On the long sides of the court, risers are placed in front of the boards to provide a slightly elevated sightline for the backmost row of courtside seats. These coveted seats are placed one-by-one by hand, eventually fully surrounding the court.

The team also brings in the tables where league officials, TV announcers, broadcast staff, and other personnel sit during games, as well as the digital advertising boards positioned in front of them. Setting up the hoops is one of the last steps. First they flip the shot clock up into position, affix its support wires to the backboard, then extend the stanchion up to its full height.

From there it’s all about calibration—assuring the hoop is level, the backboard is level, and that the both are exactly where they’re supposed to be relative to the court below. There’s also a quick check that the rim hinges down under pressure as it’s supposed to during a slam dunk, but if not, there’s always the backup hoop in the storage room that they can swap in at a moment’s notice. At this point, only small, finishing touches remain—dealing with the last few bits of wiring, putting the last few seats in place, and performing final inspections.

With that, the conversion crew is done. The clock just hit midnight, meaning the entire process, from the first panes of glass coming off to the last seat getting positioned in place, took almost exactly two hours and thirty minutes. It’s an incredible feat, and they’ll do it all over again the next night.

After the Bulls game they’re converting the arena into a stage setup for a comedy show, then two nights later the rink will return for the Blackhawks, followed by another overnight conversion to court for the Bulls. Across November alone, they’ll convert the arena twenty-one times, working tirelessly to bring Chicago its entertainment, no matter which surface it requires. As you can possibly tell, we actually filmed this video in-person at United Center.

This was a really great opportunity that not only allowed us to get this footage, but also all the information that has allowed us to make, to my knowledge, the most detailed video on how arena conversion works on YouTube. Of course, flying to Chicago and filming this was expensive, so I think this video is also a testament to the benefits of injecting a little more budget than the YouTube business model can typically support—to be honest, we can’t afford to fly out to film every video. But that’s why we’re a part of Nebula—the creator-founded streaming service that from the very beginning was focused on developing a business model that would support higher-budget projects from independent creators.

The core of how that works is having a paywall, which I know at first might seem bad, because, of course, you have to pay, but it does have its benefits. First, as a bonus, every Nebula creator uploads their normal videos there ad and sponsorship free, but really what it’s all about is the Nebula Originals. The subscription fee helps us make all sorts of great, exclusive shows and movies—like for example, if you enjoyed this video, you’d probably enjoy our series the Logistics of X, which dives into the nitty gritty of how things like ski resorts or search and rescue or commercial fishing works.

You might also enjoy Modern Conflicts, where Real Life Lore dives into the nitty gritty details of recent history’s most consequential conflicts. Or there’s a great new feature-length documentary by Tom Nicholas called Boomers, which is basically about why power and wealth has disproportionately flowed to, well, Boomers, and the consequences of this phenomenon. I could go on and on about different Originals I love, but the thing to know is that they’re great, higher-budget than what you typically get on YouTube, and the best are yet to come—thanks to the success of the platform and all the recent new subscribers, Nebula’s already working on the biggest schedule of Originals releases yet in the coming year, including a couple projects that we at Wendover are working on that I’m super excited to release.

What really seals the deal for Nebula, in my opinion, is the fact that it’s not only a home to all sorts of great, innovative, independent entertainment, but that it's an ecosystem that is simply just better for the creators. We get stable, predictable monthly income through it that’s not subject to the variability of algorithms and ad-rates. Tens upon tens of thousands of Wendover viewers have already signed up and are still subscribed, so if you want to see what it’s all about and check out all these Originals, head to Nebula.

tv/Wendover, and doing so will even get you 40% off an annual plan.

Related Videos

15:16

The Absurd Logistics of Concert Tours

Wendover Productions

2,658,188 views

23:33

The Logistics of Firefighting

Wendover Productions

1,290,809 views

14:13

The Insane Security of the White House

The B1M

1,395,015 views

24:44

Why You Can't Travel Between Hawaii's Isla...

RealLifeLore

3,977,440 views

10:19

Weird Areas Inside NFL Stadiums

FivePoints Vids

109,262 views

21:39

12,419 Days Of Strandbeest Evolution

Veritasium

3,294,492 views

29:15

The Insane Engineering of the F-14 Tomcat

Real Engineering

1,007,309 views

8:37

The Crazy-Complex Process of Organizing a ...

Half as Interesting

795,988 views

21:55

How to Control a Crowd

Wendover Productions

3,895,312 views

16:53

New York is Building a Skyscraper Jail

The B1M

1,409,524 views

14:12

How to Beat the Casino, and How They'll St...

Wendover Productions

3,578,872 views

22:54

Legendary Michigan Hockey Facilities Are I...

Spittin' Chiclets

228,549 views

22:03

How an Amusement Park Works

Wendover Productions

581,671 views

13:00

1 Year Later: How Has Argentina Been Going?

Economics Explained

838,314 views

19:48

Why Pointe Shoes Cost the NYC Ballet Nearl...

Business Insider

200,560 views

8:17

How Istanbul Moved Its Airport in Just 45 ...

Half as Interesting

746,920 views

24:50

The Gov Agency That Manages America's Wors...

Wendover Productions

1,248,180 views

12:06

Have Car Companies "Innovated" Themselves ...

How Money Works

922,948 views

22:23

The Most Important Material Ever Made

Veritasium

4,866,160 views

22:15

Every secret CIA prison, mapped

Johnny Harris

978,377 views