Today you will understand why for more than 20 years Brazil has been a pioneer in the production of biofuels. Check it out, I need 5 liters of sugarcane juice and could you give me a little piece of sugarcane too. .

. it's for an internet video. If you don't know what biofuels are, they are fuels made from organic matter.

Actual living beings. Who is with us once again in this video, is Volkswagen, the car manufacturer you already know and which is always betting on new solutions for sustainable mobility. In the first video of this series, we talked about the carbon cycle, which shows how this element moves through the atmosphere and living beings, serving as a kind of battery of nature.

And we also saw that this cycle is very delicate and if we take a lot of carbon from one place and throw it to another, as we are doing with uncontrolled carbon dioxide emissions, we could have many problems. So, today we are going to talk about one of the solutions to this problem, biofuels. This name is strange, but you must have heard of one of them.

Ethanol, biodiesel, biomethane. . .

they come from living beings and that is their great advantage because, in addition to being renewable, they ultimately emit much less carbon dioxide than common fuels. And you will already understand why. Of these three that I mentioned, for example, biodiesel is produced from vegetable oil.

We already showed it here in the Manual do Mundo and it works very well for cars that would be fueled with diesel. Here in Brazil, it is already mandatory to mix an amount of at least 12% of biodiesel in conventional diesel, but this fuel is more commonly used for large vehicles, such as trucks, buses and pickups. Biomethane is a gas that is produced from the decomposition of organic waste, manure, food waste.

. . It's the one we can do using a biodigester and the good think is that you're taking advantage of something that wouldn't be used.

But at the same time, the gas that is produced is difficult to store and use, so it usually works best for large vehicles, such as buses, or as an energy source for industrial processes. Volkswagen even has several projects to use this gas to generate energy in their factories. And I don't even need to talk about ethanol, you should already know that it worked very well as a fuel for cars here in Brazil.

Ethanol, the alcohol that we supply at the gas station, comes mainly from sugarcane. It is ground and the juice is fermented to turn the sugars into alcohol. But so far, okay, ops.

. . but so far, okay.

What is the advantage of this? Why is ethanol better for the environment than gasoline, for example? Well, the first point is that we can simply plant sugarcane.

It's different from gasoline that comes from oil, which we have to wait millions of years to be formed under the earth under very specific conditions. And the second point is that, when we burn gasoline, we are taking carbon out of an underground reservoir where it stayed for millions of years and throwing it straight into the atmosphere. This generates a large increase in carbon dioxide, which brings several problems, such as the greenhouse effect.

What's more, there's no way for this carbon to go back there, underground, to become oil again in a simple or quick way. And that's why we say that this is a non-renewable carbon. Burning ethanol also generates carbon dioxide.

The difference is that this carbon dioxide had already been captured by the sugarcane which transformed it into sugar, which was later transformed into ethanol, which we then burn and which then releases carbon dioxide and the sugarcane captures this carbon dioxide again, transforms it into sugars that we transform into ethanol and burn. . .

And because of that, if we count the carbon that is taken out of the atmosphere by sugarcane, what ethanol actually emits is much less than traditional fuels. But you are aware that all these things are not here on the table for nothing, right? Let's, then, to understand this process, try to make something from sugarcane juice, this thing that we just bought at the street market.

No, I think it's better to make alcohol. The first thing I'm going to try to do here is measure the amount of sugar in the sugarcane juice. We can do this by the density.

The sugar here is fine, we don't need to touch anything. Then, those 5 liters of sugarcane juice go into a gallon of water, and I need to prepare the little secret, which is the biological yeast. There are fungi here that will ferment the cane, will transform the sugar into alcohol.

I took a little break to go to lunch, and it bubbled up. This here is a sign that the fungus is alive, it is generating carbon dioxide. By the way, this fungus that we used here is the same one that is used to make bread, to make beer, to make wine, and these bubbles are carbon dioxide, they are the same bubbles that exist inside bread.

Also, the carbon that is in this carbon dioxide here came from sugarcane, and sugarcane took it out of the atmosphere. So, ultimately, it's not polluting. This cap that I'm going to put on is a valve.

It lets the carbon dioxide out, but doesn't let the air in. Because if air gets in, it will disturb the fungus. Now we leave it for a few days.

A sign that something is happening is if a bubble starts to come out of the valve. Look what became our sugar cane juice. Wow, I'm sure there's alcohol in here, there's a smell of strong drik that you can't even imagine.

It is very cool. Let's, then, set up our fractional distillation apparatus. It is certainly the most complex chemical apparatus that we have ever assembled here in the Manual do Mundo.

The fitting of each piece is glass, so we have to apply a little silicone grease there to seal and lubricate. The complicated thing about it is that after you've already fitted the first piece, you have to work with the thing, with these pieces more or less fitted and I'm scared to death of breaking this thing because if it breaks, it will take several days to get one new piece. .

. Let's understand now what we're doing here, right? Firstly, down here we have a heating mantle.

Why couldn't we use a bunsen burner down here? Heat this thing with fire? Because we are distilling alcohol, right?

We're not mixing alcohol with fire here. The fermented sugarcane juice was placed inside a round-bottomed flask, inside I threw a few pieces of broken ceramic pieces, this guarantees that this here doesn't start to boil overnight. It works more or less like those old milk jugs that have a funnel inside so you don't let the milk come out all at once.

The moment this starts to boil, the water and alcohol will evaporate at the same time. So, we have a fractionating column here that will make the water condense here. So, this here makes sure that we remove as much water as possible and that only the alcohol remains in the way.

Right at the top, we have a thermometer because if it gets too hot, the water will pass through, so it's nice for us to control the temperature. Finally, the condenser comes in, where the alcohol, which was in a gaseous state, will change to a liquid state. We have two hoses in it because water will flow here, so the water ensures that it stays cold all the time.

And you can see that inside there is a smaller tube, through which the steam will pass. Eventually, if all goes well, the alcohol will start to fall into that second round-bottomed flask. Wish me luck.

Generally, the water that passes through the condenser comes from the faucet and will be discarded as it warms up. But here we don't have water coming out of the faucet, so we made a circuit using a pump that was from our old laser. Sounds like a smooth deal, but we're going to be dealing with a lot of steam coming off here, hot as hell.

It's already starting to condense something in the first balloon here. Hopefully it's alcohol. The liquid came to a boil.

The water has already started to condense here, look how beautiful it is. We have our first drops. How crazy!

It's 78 degrees up here, that's really good because it's the boiling point of alcohol. This means that most of the steam rising here is alcohol. Look how beautiful it is, the liquid is sprouting, it seems that it comes out of nowhere.

This process we are doing here is practically the same thing as making a drink. Of course, a specific yeast will be used in the cachaça, there is a series of precautions with cleaning and everything else. And also in the drink ends up going a lot of water together.

What we want here is pure alcohol, so it's very likely that we can't drink this, the alcohol concentration must be very high. I hope. It pretty much stopped dripping at the temperature that the alcohol evaporates, so we can't let it heat up anymore, otherwise it will start filling up with water.

Let's see how much it yielded and if what's in here is in fact alcohol. First test is simple. As we know very well what we are distilling here, it's not a problem.

. . I can take a little sniff.

It smells like alcohol. I'm going to clean the mouth a little bit, otherwise there will be a lot of silicone with it. From 750 ml of sugarcane juice, we came out with 55 ml of something that I think is alcohol.

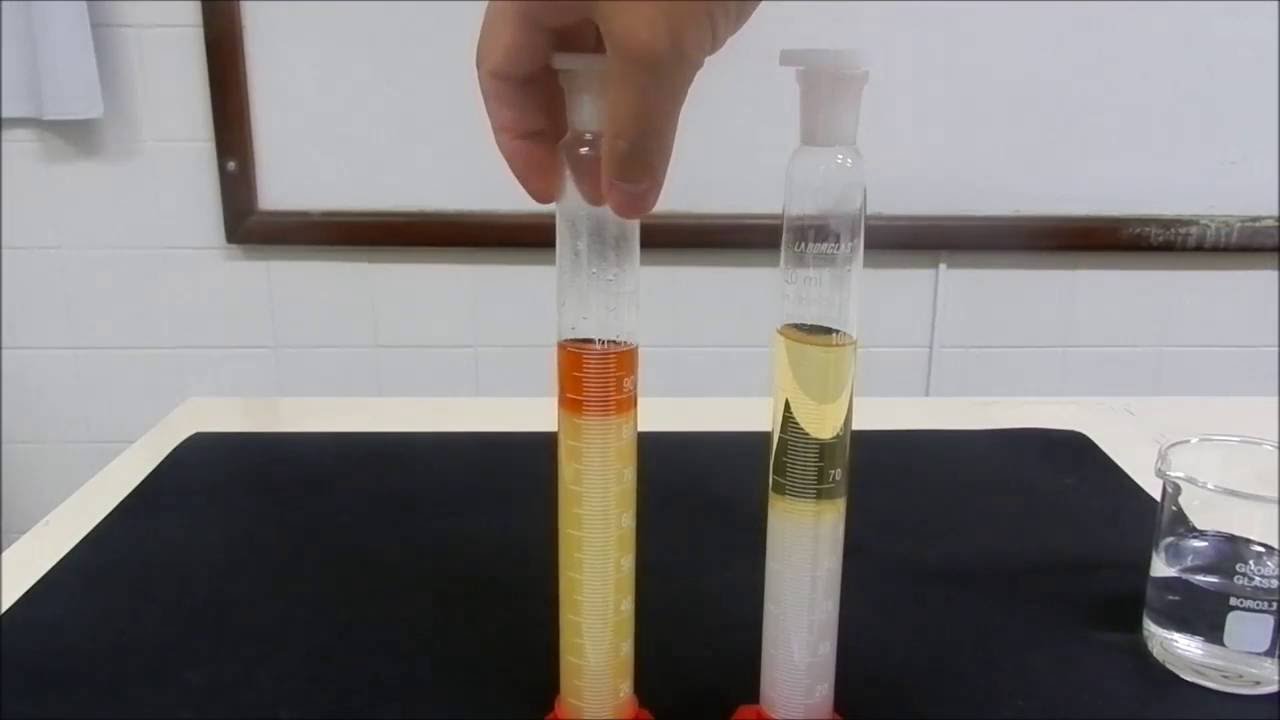

We have an instrument here to measure this. This here is an alcoholometer, it's an instrument made to measure the amount of alcohol in the water. So, if what we made here is practically water, we are going to find out now.

What's in that bottle is what we distilled before recording, which we did as a test, okay? But I also don't know how much alcohol there was in this alcoholometer. In total, we have 100 ml of this homemade alcohol.

From the smell, I would guess that we have at least a stronger concentration than a brazilian drink, which is more or less 40%. Oh boy! 78%, 77% alcohol.

This here is already stronger than the 70% alcohol that we buy at the pharmacy. And if it's strong like that, it has to catch fire easily. Let's light this thing away from all the apparatus that is all full of alcohol, right?

How amazing, I think we can agree can't we? To imagine that this came from that sugarcane juice I drank at the beginning of the video is pretty crazy. If this isn't worth a thumbs up, I don't know what is.

It worked! We have an ethanol that is not 100%, but it catches fire very well. So, if I wanted to, I could throw this into the tank of a gas car and it would be a much more sustainable fuel, right?

The engine that runs on ethanol is a little different from the gasoline engine and has nothing to do with the power itself, but mainly with the amount of air that needs to be mixed to burn each of these fuels. The first ethanol car in Brazil was tested in 1925, but the idea was not very successful, mainly because in the following years gasoline became very cheap. But in the 1970s there was an oil crisis and, then, Brazil began to put a little alcohol in gasoline as a way of reducing dependence on oil.

And this continues to this day with 27% anhydrous ethanol, ethanol without water, which is obligatorily added to gasoline. It was also at that time that the government began to encourage the production of ethanol as a fuel and in that decade the first alcohol-powered cars were produced on a large scale in Brazil. But ethanol really exploded as a fuel in 2003 with the creation of the first flex-fuel car, the Gol Total-Flex, which was developed by Volkswagen from Brazil.

This pioneering spirit of Brazilian technology brought many benefits that have lasted even to this day. For example, an engine that runs on Brazilian gasoline mixed with 27% ethanol emits 131 g of carbon dioxide per kilometer driven. It's the equivalent of this pile of coins I have here in my hand.

One important thing, in this we are considering all emissions from well to wheel, that is, not only emissions from burning the fuel itself, but from all its production, distribution and everything else. If that same car is fueled with pure ethanol, it emits 37 g of carbon dioxide per kilometer. To give you an idea of the difference, just look at the pile of coins equivalent to the carbon dioxide emitted by pure ethanol and by gasoline with a little bit of ethanol.

It is estimated that with the use of ethanol in Flex cars, Brazil has already stopped emitting 600 million tons of carbon dioxide into the atmosphere. That's about 100 times the weight of the largest pyramid in Egypt. Admit it, it's impressive the difference that a technology as important as this one can make in the long term.

So I want to thank Volkswagen again for helping us tell this story. Ethanol, the alcohol that we supply in pork, pork, pork, pork. In pork?

If you haven't seen it yet, I suggest you take a look at the video before this one where we showed how the carbon cycle works by experimenting with photosynthesis.