Bioprocessing Part 3: Purification

297.4k views2481 WordsCopy TextShare

BioNetwork

This video is the third in a series of three videos depicting the major stages of industrial-scale f...

Video Transcript:

Today, we rely heavily on biotechnology for many of the necessities of life: For the food we eat, the clothes we wear, fuels for transportation, earth-friendly plastics, pharmaceuticals to treat our illnesses, and dietary supplements to help us stay healthy. Many of these products are produced using three core biotechnology processes: Fermentation, Recovery and Purification. Fermentation is basically cell farming.

We program cells to produce a product, we nurture them as they grow and reproduce, and then we harvest them! In recovery we separate our product from the cells where they were housed. .

. And then in purification we go a step further by removing everything else that's contaminating our product. .

. leaving us with a very pure, concentrated solution. In this program, we're going to look at a typical purification process used in the manufacture of GFP - Green Fluorescent Protein.

GFP is broadly used as a biological marker because it's very well tolerated by most cells and doesn't interfere with normal cellular function. We'll examine the technologies, equipment and materials used. .

. how to prepare for the process. .

. and how the GFP purification process is managed, step-by-step. There are two main operations used within purification: Chromatography and Filtration.

Before we can appreciate exactly what these process steps are accomplishing, we need to take a closer look at what our Green Fluorescent Protein has been through so far. Back in Recovery, our harvested cells from Fermentation were homogenized. Our target protein was inside each cell, so to get at it, the cells had to be ruptured.

Homogenization freed a flood of cellular components: including membrane debris, cytoplasm, DNA, and proteins - including our target protein, GFP -- and they were all mixed into the buffering solution used to suspend the cells. Most of the solids were then removed through centrifugation (or "by centrifuge"), but the liquid that remained -- the clarified lysate, was still rich in biological products, including dissolved chemicals, proteins and other impurities. Amazingly, through Purification, we can target a single protein within this biological soup.

In our GFP purification process, we'll be using multiple types of Column Chromatography. The "column" is a cylinder filled with glass, ceramic or polymeric beads which are engineered to interact with or bind with molecules based on one or more physical properties. Chromatography relies on differences.

Each molecule has a unique set of physical characteristics; such as size, charge, or extent of interaction with water. Chromatography uses these differences to separate the target protein from other proteins and chemicals. Sometimes size is used to differentiate.

Some beads have small holes in them and can temporarily trap or at least slow down smaller molecules as they travel through the column of resin beads, while molecules too large to enter the pores move around the beads and exit the column first. This type of chromatography is called size-exclusion. In the case of charge, opposites attract, so a negatively charged chromatography bead will attract -- and bind to -- positively charged components in the process stream.

Likewise, a positively charged bead will bind negatively charged components in the process stream. This charge-based chromatography is called ion-exchange chromatography. And then there's water.

Molecules that readily interact with and dissolve in water are called hydrophilic (water-loving), while those that don't are called hydrophobic (water-hating). Proteins contain regions that are hydrophobic and regions that are hydrophilic. Because water tends to form a shield around the hydrophobic patches within the proteins, they are not exposed to interact with the resin beads.

By adding salt to the protein solution, we remove the water shield, exposing these hydrophobic patches on the protein and resin so they can interact. This is how HIC or Hydrophobic-Interaction Chromatography works. In our process, which uses ion-exchange and hydrophobic-interaction chromatography, the chromatography equipment is housed on a skid to make it compact and mobile.

The main part of the apparatus is a glass column filled with resin beads, but we also have. . .

. . .

pumps to move the clarified lysate through the process. . .

. . .

a supply hose and port to feed the column. . .

. . .

a pre-filter to remove any remaining particulates -- usually solid cell debris that has not previously been removed - before the clarified lysate enters the column. . .

. . .

an exit port for the processed solution. . .

. . .

and auto-switching valves for directing processed solution to either waste or collection. To help monitor the chromatography equipment - and the solutions flowing through the unit -- during the process, a number of sensors are located along the product flow path. There's an electrical-conductivity sensor at the column inlet.

. . .

. . a pressure sensor just before the pre-filter to help identify a filter clog.

. . .

. . a flow meter to measure the rate of solution movement through the column.

. . .

. . and an air sensor to ensure that no air has entered the flow path.

As a solution leaves the column, it passes. . .

. . .

a UV sensor that reads optical density. . .

. . .

a second conductivity sensor. . .

. . .

and a pH sensor that measures how acidic or basic the solution is. The conductivity sensors let us know when a new buffered solution has filled the column. When the conductivity reading on the exit of the column matches the reading from the sensor at the inlet of the column, then we know the new solution has completely displaced the old one.

The Ultraviolet (UV) sensor monitors the concentration of protein in the product by observing the optical density of the passing solution. This sensor works hand-in-hand with the valves on the exit of the column. Through the controller program, we can set a protein concentration threshold.

When the optical density of the solution leaving the column is below the threshold, the valve directs the flow to waste. When the optical density of the solution leaving the column is at or above the threshold, this means that solution contains our purified product. .

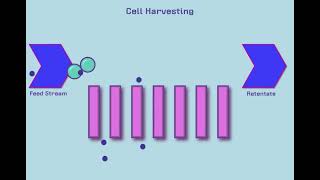

. and the solution is directed to a collection vessel. TFF - Tangential Flow Filtration - is at its heart, a simple process step.

We're going to pump a fluid through and across a special type of filter known as an ultrafiltration membrane. The size of the pores in the filter material determines what passes through and what's held back. As with almost any filtering process, we can choose what we want to keep.

The solution that passes through the membrane is referred to as the permeate. Because the pores of the ultrafiltration membrane are small enough to keep the product from passing through, the permeate contains no product and is sent to waste. The portion of the feed stream that does not permeate the membrane is called the retentate.

It contains the retained product and is the stream we are most interested in. What makes TFF different is a core technology that enables it to be faster, more efficient, more flexible and even self-cleaning! In conventional -- or terminal - filtration, a fluid is pumped directly into a filter.

The particles within the stream that can't fit through the pores of the filter build up at the filter surface, eventually clogging it. In Tangential Flow Filtration, the stream moves across the filter -- that is, tangential to the filter - instead of directly at it. The cross-flow current actually picks material back out of the filter media or membrane and into the stream.

This retained material -- called retentate -- is recirculated to the supply tank and will continue to loop through the filter for as long as the process runs. We'll be using TFF for two different tasks within the purification process: Concentration and Diafiltration. We are processing purified GFP from a chromatography step.

The fluid from the chromatography step is purified Green fluorescent protein dissolved in a buffering solution In Diafiltration, we add new buffer to the GFP retentate, while displacing the old buffer; effectively exchanging buffer solutions! NOTE: the GFP is retained by the membrane. If we don't add a new buffer, then we're concentrating our solution.

Concentration is simply the removal of water and buffer components from the feed solution that results in a more concentrated solution of Green Fluorescent Protein. From operation to operation or product to product, the purification process can look quite different. It could be as simple as a single Chromatography step, one cycle of TFF to concentrate the product, and final filtration.

. . Or it could involve several different types of Chromatography, Diafiltration between Chromatography steps, and a final conventional filtration.

Our Green Fluorescent Protein process is pretty typical of the process for biopharmaceutical products: The clarified lysate will be pre-filtered. . .

Go through Anion Exchange Chromatography. . .

and the GFP collected and pooled. Next, Ammonium sulfate will be added to make the solution high-salt. .

. Followed by Hydrophobic Interaction Chromatography- HIC. The GFP is then collected and pooled again.

. . The solution then goes through a TFF ultrafiltration step -- which includes concentration of the GFP followed by Diafiltration to exchange buffer solutions and remove salt.

And the process finishes up with Final Filtration into bulk bottles or bags It's time to gather everything we'll need for the Purification process and ensure that the area and equipment are ready to go. The Chromatography skid and TFF system are checked for proper operation. .

. process hoses are attached and examined for leaks. .

. We verify that we are using the correct column resin and that the resin is properly packed. the column is filled with a storage buffer.

. . and the product path is checked for trapped air and purged if necessary.

Our raw materials include the clarified lysate from the Recovery process, various buffer solutions that are tailored to specific process steps, and Ammonium Sulfate that we add to one of the buffers to make it high-salt. The Purification process is managed through the use of a Batch Record. There is a separate Batch Record for each processing operation.

These documents lead the operator through the process, step-by-step. . .

with each step requiring a sign-off and separate verification by a second operator. The Batch Record also includes spaces for documenting times, activities, operation steps and instrument readings. Before the process can begin, the Purification area must be cleaned, disinfected and organized.

Any unnecessary equipment or materials are removed. . .

All equipment must be cleaned, sanitized, and set up as required by Standard Operating Procedures. . .

All required materials and documentation must be gathered and prepared. . .

before the process may begin. The Purification process begins as the transfer tank of clarified lysate from the Recovery process is connected to the inlet pump on the Chromatography skid. The first Chromatography step in our Green Fluorescent Protein purification process is Anion-Exchange.

At this point in the process, the pH of the clarified lysate is about 8. 0, which means that the protein is negatively charged. Because it is negatively charged, GFP will bind to the positively charged anion exchange resin.

The pump draws the lysate from the vessel. . .

past the first conductivity sensor and pressure sensor. . .

and through the 0. 45 micron pre-filter. The pre-filter removes any residual cell debris or other particulates that may have contaminated the solution.

If the pre-filter begins to clog, the pressure sensor at the inlet side of the filter will register a rising pressure. . .

and the controller will signal the need for a filter change. After pre-filtering and before the column, the lysate passes through. .

. a flow meter. .

. and an air sensor. Then, as the lysate passes over the resin beads, the negatively charged protein binds to the positively-charged beads.

The solution leaving the column passes a UV optical density sensor, a conductivity sensor and a pH sensor. The optical density sensor's low readings confirm that the GFP is not in the solution, so the outlet valve sends the solution to waste. When all the lysate has entered the column -- or when the capacity of the beads to bind the protein has been reached, it's time for Elution.

Elution is the release of, in this case, Green Fluorescent Protein from the beads by using a new solution -- in this case a buffer that includes NaCl (sodium chloride) - solution. As the new buffer is pumped through the beads, at some point the GFP no longer binds to the beads and is released into the buffer. The resulting product stream is usually referred to as the eluate (el-you-ate).

The UV optical density sensor, which measures protein concentration, indicates when product begins eluting from the column. At this point, outlet valves are switched to allow flow of the eluate -- the product stream -- to a collection vessel. When the UV sensor indicates that all of the GFP has come off of the chromatography resin, the outlet valves are switched to waste.

When all of the eluate has been collected and pooled, the Anion-Exchange Chromatography step is finished and it's time for HIC-Hydrophobic-Interaction Chromatography. Hydrophobic-Interaction Chromatography is based on the principle that hydrophobic chemicals on the resin surface will bind to hydrophobic patches on the GFP protein. In order for this to occur, the resin and protein eluate have to be in a high salt environment to remove the water shielding.

The salt we use is ammonium sulfate. To remove the attached GFP protein from the HIC column we simply lower the salt concentration during elution causing the water shielding to reform and the GFP protein detaches from the resin into the elution stream. The protein-rich eluate is collected and pooled.

The product is now ready for the last major step, TFF. At this point in the process, Tangential-Flow Filtration will be used to concentrate and diafilter the GFP product stream. The eluate is rich in Green Fluorescent Protein, but it's still too dilute.

. . and too high in salt.

As the solution moves through the TFF apparatus, it leaves the supply tank. . .

is pulled through a pump. . .

past a pressure sensor. . .

and then across the filter membrane. Everything that passes through the membrane, including the buffer solution, is known as permeate -- and -- for this process - is sent to waste. The GFP protein is larger than the pores of the membrane and therefore is retained.

The retained material -- called retentate -- is recirculated to the supply tank. Recirculation of the feed continues until the desired concentration of GFP is achieved. Following concentration, and while the protein solution is recirculating, a new solution -- a storage buffer - is added to the feed.

In effect, the protein is being washed by the flow of a new buffer solution in, and the old buffer solution out. As this diafiltration step proceeds, the buffer solution that is being added to the feed replaces the buffer solution that the GFP was originally in, effectively removing any remaining salt as well. When this process is complete, the GFP solution is routed through a 0.

22 micron final filter. . .

and then collected in appropriate containers -- usually bottles or bags. The Purification process is complete. The Green Fluorescent Protein concentrate can now move downstream to final Fill/Finish to be freeze-dried and packaged.

Related Videos

15:04

Bioprocessing Part 1: Fermentation

BioNetwork

827,778 views

7:16

Introduction to Tangential Flow Filtration...

Biomanufacturing and Bioprocessing

64,438 views

11:04

Bioprocessing Part 2: Separation / Recovery

BioNetwork

329,514 views

21:02

Cody's Algae Panel

Cody'sLab

3,076,780 views

20:09

07 - Size Exclusion Chromatography and AKT...

Eroglu Lab

30,716 views

1:00:41

Bright colorful neon stars flying in a bla...

TİME TO RELAX 4K Amazing Relaxing Screensavers

1,264,628 views

14:45

Aseptic Gowning for the Cleanroom

BioNetwork

363,966 views

7:08

Tangential Flow Filtration to Concentrate ...

ECETOC

42,856 views

1:06:30

Lecture 32 Isolation and Purification of P...

IIT Kharagpur July 2018

53,025 views

26:14

Environmental Monitoring (EM)

BioNetwork

99,360 views

14:14

Bio-processing overview (Upstream and dow...

Animated biology With arpan

193,922 views

6:33

Assembly of the Pall Minimate™ Tangential ...

Cytiva

3,623 views

11:44

Protein Purification

Creative BioMart

236,114 views

17:04

Refinery Crude Oil Distillation Process Co...

ChemicalEngineering

1,295,765 views

3:01

A Day in the Life of a Clean Room Technician

FUJIFILM Dimatix, Inc.

171,075 views

2:37:05

Wastewater Training, 1 of 3

NEIWPCC

489,171 views

58:07

Real-Time PCR in Action

USDA Animal and Plant Health Inspection Service

302,478 views

16:56

How To Make Ruby in a Microwave

NightHawkInLight

2,377,892 views

18:30

Properties and Grain Structure

moodlemech

1,243,747 views