Supply Chain Management In 6 Minutes | What Is Supply Chain Management? | Simplilearn

1.1M views995 WordsCopy TextShare

Simplilearn

🔥Explore Professional Certification Courses from Simplilearn - https://www.simplilearn.com/?utm_ca...

Video Transcript:

[Music] alex is a major tech enthusiast recently he attended a virtual apple launch event where he witnessed the capabilities of the all-new iphone 13 series instantly he made the decision to get an iphone 13 pro however he missed the pre-booking deadline and he's been waiting for this phone to hit the e-commerce sites ever since after waiting for a long time he visited the offline apple store where the store representative informed him about an ongoing delay in the production of iphone 13 pro due to the supply chain inefficiency alex then went to a couple of more

trusted apple reseller outlets and received the same response he then became intrigued about this term supply chain and how it affects the production of a big corporation like apple inc therefore he began exploring this topic he spoke with his friend rachel who works at apple inc to learn about supply chain management and how the chain is disrupted due to international chip shortage rachel explained to him about supply chain management using applelink's example she said if you order an iphone from the apple store you'll notice that apple is not precisely delivering the product on its own

all the iphones available in apple store are majorly manufactured at the shinsen assembly plant in china but before that raw material suppliers from all around the world deliver goods needed to manufacture an iphone to this assembly site and once the product is assembled it gets shipped to the storage warehouse and then to your doorstep by third-party vendors like fedex or ups this means entities such as raw materials supplier manufacturer and third-party logistics vendor are in consistent communication with each other until the iphone reaches you these entities and their communication involved in product manufacturing to product

delivery is collectively considered as a supply chain after listening to this alex asked rachel how apple inc has implemented this supply chain and how can one design a sleek strategy to manage a supply chain that is not overly influenced by external factors in response rachel explained well there are five stages for building supply chain management and apple has adopted these stages while building the supply chain management strategy the first stage of building a supply chain is planning an operational strategy apple since its inception has had a clear goal to provide the best personal computing devices

to consumers the initiative of apple to scrutinize each app or program before launching it on the apple app store makes all apple devices more secure these pre-planned actions or strategies have been the most vital usps of this organization the next stage is sourcing in this stage apple acquires equipment and materials from suppliers and then ships them to the offshore assembly factory in china the 120 hertz screens are exported from samsung's assan plant foxconn ships batteries and the processing chips are manufactured and exported by tsmc then comes the third stage known as making this is the

stage where apple manufactures its products the outsourced chinese assembly plant majorly assembles all apple products and ships them to the warehouses or distribution centers spread across multiple continents after that the next stage of supply chain management delivery comes into play here the products ordered online get shipped to the doorstep of consumers from storage warehouses whereas the distribution centers on the other hand send items to retail stores for offline sales this whole shipping process is carried out by third-party logistics vendors such as fedex supply chain management's last building stage is returns here the faulty or damaged

products during delivery get shipped back to the storage warehouses and then the assembly planned for refurbishment statistically speaking 97 of apple's supply chain is all about outsourcing agreements and collaborations which has helped apple become the best computing device producer however due to the recent worldwide chip shortage apple's supply chain has been affected adversely the world was shut down because of the covet 19 pandemic and many factories also went down with it leaving chip manufacturing materials unavailable for months increased consumer electronic demand in recent times and scarcity of semiconductor supplies has put pressure on apple's supply

chain prompting the company to halt production of 10 million iphone 13 devices after listening to rachel alex learned why there is a constant delay in the delivery of iphones and became more patient about his desire to buy an iphone on that note here's a question for you from the given options which option does not fall under the stages of supply chain management a planning operational strategy b sourcing c making d disposal do give it a thought and leave your answers in the comments section below three lucky winners will receive amazon gift vouchers with the help

of an apple inc case study we explored how a supply chain management strategy can be established this domain of business management is crucial for any product or service based company in the long run a well-managed supply chain can lower operational expenses allowing a firm to gain more profit it can also improve corporate brand recognition and customer service hence companies invest a great deal on their supply chain they constantly hire professional supply chain management experts these professionals are tasked with managing logistics updating the company's inventory and conducting a thorough evaluation of the manufacturing cycle to discover

and correct laws that is the reason why these scm professionals are compensated really well according to payscale the average salary for supply chain managers is eighty-four thousand dollars per annum whereas in india the average annual salary is around 8.5 lakhs per annum we hope you enjoyed this video if you did a thumbs up would be really appreciated here's your reminder to subscribe to our channel and click on the bell icon for more on the latest technologies and trends thank you for watching and stay tuned for more from simplylearn [Music] you

Related Videos

12:08

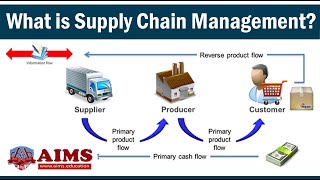

What is Supply Chain Management? Definitio...

AIMS Education, UK

2,220,969 views

54:43

Why Global Supply Chains May Never Be the ...

The Wall Street Journal

7,062,223 views

8:08

Lean Six Sigma In 8 Minutes | What Is Lean...

Simplilearn

2,178,946 views

44:11

Think Faster, Talk Smarter with Matt Abrahams

Stanford Alumni

1,845,151 views

15:46

How Amazon Beat Supply Chain Chaos With Sh...

CNBC

3,216,780 views

8:05

Module 1: What is Supply Chain Management?...

W. P. Carey School of Business

3,095,768 views

18:25

SUPPLY CHAIN Interview Questions & ANSWERS...

CareerVidz

16,693 views

5:15

How Companies Are Overhauling Supply Chain...

The Wall Street Journal

330,071 views

8:59

Six Sigma In 9 Minutes | What Is Six Sigma...

Simplilearn

2,795,962 views

13:43

Top 10 Highest Paying Jobs For 2025 | Best...

Simplilearn

14,464 views

25:48

Logistics of the Future | Free Documentary

Free Documentary

637,113 views

58:20

Think Fast, Talk Smart: Communication Tech...

Stanford Graduate School of Business

41,733,607 views

11:40

What Is a Supply Chain Analyst? - Responsi...

Jay Feng

36,133 views

10:45

Explained Supply Chain Management in 10 Mi...

Leaders Talk

125,531 views

12:54

The Power of Logistics | Terry Esper | TED...

TEDx Talks

211,395 views

44:03

Procurement Management | Types of procurem...

Great Learning

52,781 views

11:03

How to Fix Broken Supply Chains | Dustin B...

TED

114,474 views

3:40

What is Supply chain Management ( SCM )? |...

Educationleaves

205,999 views

14:23

10 Things you should know about a career i...

MVC Logistics Academy

89,449 views

6:15

What Makes a Good Supply Chain Manager? - ...

Supply Chain Secrets

51,057 views