How City Water Purification Works: Drinking and Wastewater

736.22k views1274 WordsCopy TextShare

Animagraffs

Cities purify millions of gallons of drinking and wastewater daily. This incredible process happens ...

Video Transcript:

I'm Jake O'Neal, creator of Animagraffs. And this is how city water purification works: from drinking water to wastewater to nature and back again. Let's start with drinking water, which comes from surface sources like rivers, lakes, and reservoirs, or from underground wells or springs.

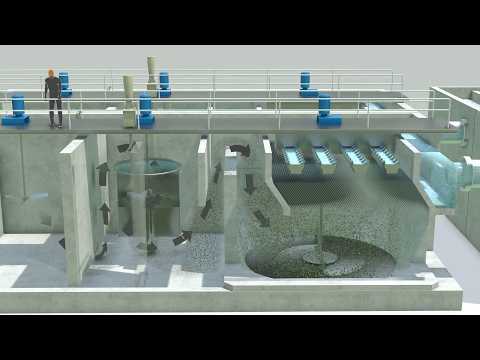

Water treatment plants have near endless variations in design, so I've chosen major components and processes to create a general working model. Cylindrical intake screens are placed in a reservoir in such a way to best avoid ingesting silt from the reservoir bottom, or floating material from the surface. A lift house with vertical pumps draws water from a well and into the treatment plant.

The purification process starts with coagulation and flocculation. Particles suspended in water, like clay, sand, and some larger organic particles such as algae, have an inherent electric charge that causes them to repel each other. Coagulants are substances with opposite electric charge that neutralize these particles and encourage them to stick together into clumps called "floc".

The coagulant and water is vigorously mixed, and floc clumps start to form. To make floc particles heavier and therefore even easier to eventually settle out, micro-sand is added as the water is drawn through a special mixing tube, with a polymer to help the sand stick. The now flocculated water flows through a set of baffles to slow its turbulence for the settling process.

As the water travels upwards, heavy floc particles quickly settle to the bottom of the tank. Any remaining suspended particles collide with an array of angled plates, and slide down to the settling zone. Slowly rotating scraper blades continuously remove the combined sludge and sand layer from the bottom of the tank while clarified water flows upwards into collection troughs.

At this stage the water already looks clear, and a lot less cloudy. Now it's on to ozonation and filtration to treat microscopic taste and odor causing agents. These can include inorganic elements such as iron or sulfur, or harmful bacteria and viruses.

In the ozone tank, ozone gas bubbles are injected into the flowing water through diffusers. The tank is divided, which slows the flow and gives the water a longer path with more time for ozone to do its job. An ozone gas molecule is made up of 3 oxygen atoms.

The normal oxygen we breathe has just 2 oxygen atoms. When ozone is injected into the stream, the extra oxygen molecule can bond with contaminants, or "oxidize" them, with various desirable results. For example, oxidized metals have a weaker bond with water, and are therefore easier to extract.

Oxygen also bonds with elements in virus or bacteria cell walls, disrupting their function, and altering their surface charge for easier filtration downstream. When ozone gives up its extra oxygen molecule it just becomes normal oxygen, leaving no byproducts in the treated water, unlike other purification methods such as chlorination. The water flows to the filtration stage to remove the oxidized particles, and any other remaining contaminants.

Water travels through a dense layered bed of activated carbon granules and microsand. It's called "activated" carbon because the resulting engineered granules, which are processed from common materials like wood, coal, or even coconut husks, have a relatively huge surface area with many features and pores, giving ample opportunity for contaminants to catch or stick to the surface as water passes through. Generally speaking, the activated carbon layer filters biological and chemical elements, while the sand layer filters inorganic elements like unwanted metals.

Passing particles stick to a carbon or sand granule's surface due to naturally occurring attractive forces, called Van Der Waal's forces. The filtered water flows to final disinfection in the UV tank. Water passes through banks of ultraviolet lights.

UV light at various wavelengths can destroy or disrupt viral, bacterial, and other pathogen's DNA or cellular structure, effectively destroying them. The water is now ready for public consumption. It flows into a what's called a clearwell for storage, or into the municipal system for use.

Now let's look at what happens to water after we use it! Wastewater flows from our homes through the municipal collection system or city sewer pipes to a wastewater treatment plant, where it's processed before being released into a natural water source. The headworks is a group of processes that removes large debris and heavier inorganic particles from the incoming wastewater flow.

Water arrives at the plant mostly by gravity. Depending on local geography, it may need to be pumped or lifted into the wastewater plant. Screw pumps are a rugged, mechanically simple design built to handle this coarse incoming mixture.

Bar screens trap debris, including literal tons of items that really shouldn't be flushed or sent down the drain, such as baby wipes, q-tips, diapers, paper towels, medication, and so on. A moving platform called a “rake” scrapes the bars, removing the debris for separate processing and disposal. The water then travels to the grit chamber to remove heavier, inorganic gritty particles like sand, silt, clay, coffee grounds, eggshells, and so forth, while allowing lighter organic material to pass through.

A spinning plate with fins, called an impeller, creates an axial vortex which is a sort of vertical spiral force along its spin axis, at a specific speed so as to catch particles in a defined weight range. These heavier grit particles are forced down chamber walls and out at the bottom. The grit is collected to undergo its own separate dewatering and washing process.

The wastewater leaves the headworks towards primary clarification. Primary clarification separates organic matter from the wastewater. Water flows in at the center of large circular basins, called sedimentation tanks.

A baffle slows down the flow rate to aid the settling process. Floatable solids like grease and oil drift to the top of the tank. A rotating skimmer continually pushes this material into a collection trough.

Settleable solids sink to the angled bottom of the tank and form a sludge. Scraper arms push the sludge out of the tank into a sludge pit. This organic matter has its own purification process, and can eventually be used, for example, as fertilizer.

A baffle at the edge keeps floating material from mixing with outgoing processed water as it flows over a lip at the edge of the tank called a weir. At this point, the water is starting to look a lot cleaner and clearer. The water flows to secondary treatment, which in our model, is an aeration tank.

In the aeration tank, helpful microorganisms are mixed in with wastewater. These are special bacteria and protozoa that consume biodegradable waste products, such as human waste, food waste, soaps and detergents. These helpful microorganisms also need oxygen to live, so air is vigorously pumped through the mixture.

They either directly absorb soluble particles as food, or emit enzymes that eventually allow solid particles to be digested. The microorganisms naturally stick together over time, forming clumps called floc. The water and floc mixture travels to final clarification.

Here, the floc sinks to the bottom of the tank. Some of this settled floc is collected for re-use in the aeration process as the helpful organisms are still active. Processed water flows over the edge of the tank en route to final disinfection in a UV light exposure tank.

After final disinfection, the water is ready to be released back into nature. A specially designed outfall pipe with diffuser nozzles mixes treated water evenly while causing minimal disruption to existing environmental conditions. Treated wastewater and untreated drinking water almost never share the same immediate natural water system, though some rare places in the world are challenging that model.

Related Videos

10:55

How Chicago Cleans 1.4 Billion Gallons Of ...

Insider

951,574 views

20:32

Why Is Desalination So Difficult?

Practical Engineering

3,156,626 views

9:16

Underwater Constructions | How do Engineer...

Lesics

8,986,558 views

15:36

What's inside of the Gateway Arch? (St. Lo...

Jared Owen

1,838,522 views

12:28

How Sewers Work (feat. Fake Poop)

Practical Engineering

5,092,065 views

14:38

Newly Discovered PRIMITIVE WATER FILTER! 1...

Clay Hayes

2,992,671 views

25:39

Wastewater Treatment Plant Tour

KingCountyWTD

128,041 views

12:53

Zurich Werdhoelzli: How does a sewage trea...

Stadt Zürich

702,794 views

22:12

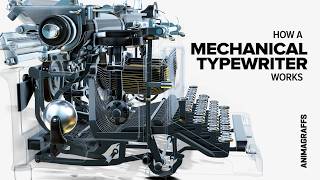

How a Mechanical Typewriter Works

Animagraffs

367,901 views

17:30

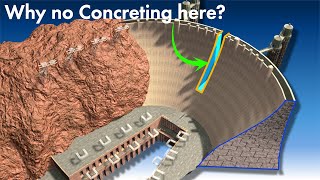

Constructing the Wonder: Hoover Dam Secret...

Lesics

2,444,182 views

6:40

Water Treatment Plant Tour

City of Winnipeg

76,227 views

7:20

How a Mechanical Watch Works

Animagraffs

4,578,522 views

11:58

Tidal energy could be huge – why isn't it?

DW Planet A

3,512,393 views

9:49

3.8 Anaerobic Digestion Technologies and O...

Municipal Solid Waste Management

864,627 views

15:11

I Built a Wildlife Pond - here's what happ...

Stefano Ianiro

23,062,029 views

19:58

Everything About Irrigation Pivots (Farmer...

SmarterEveryDay

5,394,215 views

23:52

Do Water Filters Really Purify Your Water?...

CNA Insider

1,552,082 views

21:07

What stops rain from flooding your city?

Andrew Lam

932,723 views

17:21

Automated Hydrogen Generator

Hyperspace Pirate

1,477,364 views

15:17

Unlimited Fresh Water: Can MIT's Breakthro...

Ziroth

1,184,023 views