I Saved an Electron Microscope from the Trash

470.46k views6075 WordsCopy TextShare

ProjectsInFlight

Support me on Patreon: https://www.patreon.com/projectsinflight

In this video I show off the newest...

Video Transcript:

hey everybody check out the newest addition to my lab this is a scanning electron microscope when this machine was new it would have cost over $100,000 this particular machine was broken so I got it for free after months of effort I managed to get it working again this video is the story of how that happened let me start from the beginning microscopy is one of my oldest Hobbies I got my first toy microscope in grade school and in high school I saved up my money and bought a much nicer one you might even recognize it

as it's been used multiple times on this channel fast forward to college and I managed to snag an internship at a lab researching Nano structures these structures were so small that even an optical microscope was not enough to see them and so I received training on the lab's scanning electron microscope or sem for short I was immediately Blown Away by the images produced by the scanning electron microscope features that were far too small to see under an optical microscope were visible in extreme detail in the electron microscope but how was this possible well it all

comes down to wavelength you see the wavelength of light imposes a limit on the maximum resolution of a microscope visible light has a wavelength between 400 and 800 nanom around the size of a bacterium and so Optical microscopes really can't see anything smaller than that electron microscopes as the name suggests use electrons instead to create an image the wavelength of these electrons can vary but are typically around 100 P this is more than 1,000 times smaller than the wavelength of visible light well into the X-ray range it cannot be overstated how much of an improvement

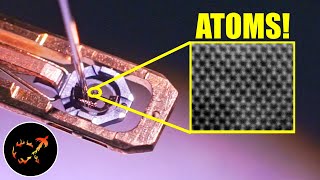

this is over an optical microscope Optical microscopes typically max out at around 1,000 times magnification whereas some Modern electron microscopes can exceed 1 million times magnification allowing us to see even individual atoms themselves the first day I used the microscope I decided right then and there that one of my life goals would be to own one of these beautiful machines myself there was just one problem unlike Optical microscopes which are small and relatively inexpensive electron microscopes are behemoths usually weighing in at thousands of pounds and occupying an entire room on their own they are also

extremely expensive usually hundreds of thousands of dollars buying new was out of the question however I realized that as technology improves Labs replace their equipment and so occasionally old electron microscopes go up for sale thus began my decade long search for a used but functional sem I found a few potential candidates over the years but they were all either too expensive or entirely broken broken however about a year ago I stumbled upon a small scanning electron microscope on Craigslist of all places it was made by a company called jol in the ' 80s and 9s

it was relatively small for an sem at least only about 800 lb and the size of a single desk however when I inspected it in person I found that it was totally nonfunctional the lab selling it told me that they tried to repair it themselves but got nowhere so they promptly stuck it in a warehouse and forgot about it for 10 years I declined to buy it but I told them if they ever wanted to scrap it I would gladly take it off their hands for free 6 months later and to my complete surprise I

got a call back from the same lab apparently no one else had been interested so I got a friend and a Truck and went to pick it up along with a box of manuals and schematics it was then that I realized I was in over my head I only knew the very basics of how a machine like this worked and certainly not enough to repair one to remedy that I devoured information from books and online quickly learning how these machines were built and how they worked during that process I managed to find this Discord channel

of hobbyist sem owners and even found a couple of people Martin and monochroma who were also fixing up their very own JSM 5200s What in incredible luck I shared my manuals and schematics with them and from then on when something was not behaving correctly on one machine we could leverage the other machines as a reference and more easily understand what needed to be fixed so how does a scanning electron microscope work anyway well to start a scanning electron microscope does not image the whole sample at once instead it builds the image pixel by pixel here's

how we start by creating a very narrow of electrons this beam strikes a very small spot on the surface of an object to be inspected this causes the surface to emit electrons itself a detector counts the number of emitted electrons and that number determines the brightness of a single Pixel on the screen then the microscope moves the beam to the next spot to create the next pixel then the next and so on until the beam has covered the entire area to be inspected you can see on the display that we have a very rough image

of our sample to fix this we can make the Electron Beam more narrow which will make the pixels smaller and result in a higher resolution image in order to increase magnification however all we have to do is simply scan a smaller area pretty cool huh okay let's talk Hardware the microscope itself consists of several components the most important of which is the column this is where the magic happens electrons are generated at the top of the column here and are fed downward through a series of lenses and apertures which creates a narrow beam the beam

passes through a set of deflection coils which allows the microscope to precisely control where the beam lands on the sample the beam strikes the surface of the sample causing it to emit electrons which are then captured by this detector and counted the signal from the detector is then displayed on this viewing screen as our image now everything I just described is essentially the heart of the microscope however there are many other necessary components that this microscope needs to function first there is a vacuum system electron beams can't travel through air and so the entire column

needs to be held under a vacuum and not just any vacuum we need around 1 billionth of an atmosphere to accomplish this we must use two pumps this is called a defusion pump diffusion pumps are pretty crazy they have no moving parts and operate in entirely by boiling a special type of oil diffusion pumps can reach incredibly low pressures however they cannot exhaust directly to Atmosphere they can only exhaust into another vacuum pump thus we need a second vacuum pump just a normal mechanical pump for that purpose diffusion pumps also generate a lot of heat

so they require water cooling as well next we have a bunch of different power supplies including one that goes up to to 25,000 volts this is the accelerating voltage that creates the Electron Beam after that we have a bunch of sensitive analog circuitry this is a bunch of amplifiers and stuff that carefully control the current to the electromagnetic lenses that deflect and focus the Electron Beam they are also responsible for magnifying the minute electrical signals that are produced by the detector in addition to that we also have digital circuitry in the form of a rudimentary

computer that manages the vales and other components and keeps the sem operating smoothly finally we have the user interface made up of the main display which shows us the image and a small LCD which shows us the system status as well as a bunch of knobs and buttons which allow us to control the focus and magnification of the microscope and that's basically everything okay so we finally have the microscope the documentation and a rudimentary understanding of how this machine is supposed to work but how do we actually repair this thing well given that it won't

currently turn on it makes sense to check out the power supplies first this machine runs on 100 volts ac which is provided by this varc here which plugs into a standard 120 volt wall outlet I first checked the varak and confirmed it was outputting 100 Vols AC before connecting it to the machine while I'm back here I'm also going to unplug the diffusion pump heater the diffusion pump requires a constant source of cooling water and vacuum and isn't necessary for the upcoming tests okay the machine's power is connected here we go okay that was anticlimactic

it looks like the machine doesn't have power for some reason let's start by checking the power entry area it looks like the 100 volts comes in here goes through a couple of fuses and a couple of Transformers which feeds a bunch of different power supplies well right off the bat I found a blown fuse I replace the fuse turn the machine back on and immediately blew the fuse again okay I probably should have seen that one coming something Downstream is clearly drawing too much current or is shorted out entirely according to the schematics this fuse

protects Transformer T2 which is this monstrosity here it's a large Transformer with one primary and seven secondary windings I checked each winding with an OHM meter and found that one of the windings is clearly shorted what probably happened is that over the last 30 years or so the old insulation on the windings deteriorated and shorted out the Transformer because of the way it's constructed the only way to repair the Transformer would be to unwind then rewind all eight coils by hand realistically this Transformer is scrap now sourcing a brand new replacement for a bespoke Transformer

like this is unrealistic fortunately we have some Alternatives instead of one Transformer with one primary and 7 second coils we can instead replace each secondary with its own transformer and that's exactly what I did actually it turns out that some of the secondaries were for optional Hardware that this microscope doesn't have so this was all I needed there was one hiccup though remember that this is a 100v machine and most Transformers are rated for 120 volts this complicates the process of sourcing Replacements because a 120 to 12vt Transformer becomes a 100 to 10 Vol Transformer

instead I had to account for that for my 60 volt power supply for example I used this large 72 volt toroidal transformer for my 12vt power supply I used a 12vt Transformer this only outputs 10 volts but that's acceptable because it feeds into a linear voltage regulator that's tolerant to a lower input voltage I mounted the Transformers to an aluminum plate and found a place for them in the cabinet next to T2 I checked each output to make sure it was correct and then wired it in let's see if we can turn the machine on

now okay that's not right what in the world is going on here well as far as I can tell all of the digital logic is going completely Haywire that is not a good sign I checked the schematics and found that the digital logic is fed by two different 5V power supplies these power supplies are these ancient 5volt linear Regulators with massive heat sinks I tested them and found their output voltage was wildly erratic so they need to be replaced now this part is so old that I couldn't get any relevant info on it I ended

up using a bench power supply to provide 5 volts manually and found that the machine Drew about 1 amp the common 7805 linear regulator can do that much easily however this little package cannot dissipate the excess heat without a better heat sink so I made one out of an aluminum plate and some thermal paste I wasn't sure if it could handle the power dissipations so I tested it on my bench surprisingly dissipating 7 watts of power only raised its temperature to about 50 c I went ahead and mounted the new regulators and wired everything back

together let's see if we've made any progress hey much better it looks like the digital logic is at least somewhat working now this LCD displays some useful diagnostic info about the machine such as the operating current of various components as well as the current vacuum levels though the vacuum level is in percent rather than an actual pressure unit like T weird now that the electrical power seems like it's working it's time to test the vacuum system I started by testing the pump alone and verifying that it reached about 10 millor which is not fantastic but

sufficient and probably expected for a pump this sold moving forward I'm only going to connect the roughing pump and keep the diffusion pump off this means that our lowest vacuum should be roughly 10 millor assuming we have no significant leaks I turned the vacuum pump on and use the manual controls to open the valve and Evacuate the chamber but pressure readout on the LCD didn't change odd perhaps the gauge is broken well sort of the pressure gauge outputs an analog voltage which is compared with a set point voltage in order for the machine to operate

all of that worked just fine thankfully quite separately however the analog voltage feeds into an analog to digital converter so that it can be displayed on the LCD that part of the circuit seems to be broken I tried to fix it but was unsuccessful now fortunately this won't keep the machine from operating however it is pretty important that we know the pressure in the chamber at all times running the machine with a leak will lead to an insufficient vacuum which at best will reduce image quality and filament life and at worst can lead to a

catastrophic failure of the diffusion pump we really need a vacuum gauge to that end I manufactured this aluminum adapter so that I could connect my own vacuum gauge and measure the pressure myself the gauge will replace the X-ray detector for now this gauge outputs a voltage between 0 and 10 volts which can be converted to a pressure reading using this formula for expediency I am simply hooking up a voltmeter and I will overlay the actual pressure in the video where necessary okay so I turned on the rotary pump again and now I can definitely see

the pressure in the chamber dropping that's a good sign however after leaving the system running for several minutes I saw that the pressure bottomed out at only 200 millor we saw earlier that the pump could do 10 milor so this definitely indicates a leak somewhere in the system I took a closer look at the connections and yeah holy cow these 30-year-old rubber hoses are not looking too good they have deep cracks almost all the way through I don't know for sure if they are leaking yet but even if they somehow are not leaking if they

suddenly fail while the diffusion pump is running and expose the pump to Atmosphere that's not a good day these definitely have to be replaced I measured the inner and outer diameter of the hose and unfortunately I wasn't able to find an exact replacement the hose fittings are 24 mm which is not a standard size to add insult to injury replacement rubber hoses like this are quite expensive a few feet of Hose would be over $200 which is a bit more than I want to spend since at this point I'm not even sure the microscope will

function at all fortunately I was able to find this 7/8 in about 22 mm PVC hose reinforced with a steel coil this keeps it from collapsing under vacuum but it also might keep the 22 mm hose from stretching over the larger 24 mm fitting only one way to find out after some persuasion I was able to make it work just fine thank goodness I replaced all of the rubber hoses and made sure to grease the joints with high vacuum grease and also used hose clamps to ensure a good seal I fired the machine back up

and darn still leaking that's unfortunate I wonder where the leak is I spent quite a while inspecting various parts on the machine using the valves to isolate different segments and then watching as the pressure slowly climbed however nothing seemed like it was actually leaking I also tried using a stethoscope to hear the leak but to no avail I even tried flooding the various connections with 100% isopropanol which is another method to check for leaks the isopropanol if sucked in will vaporize and cause a spike on the pressure gauge however I got nowhere every joint on

the machine seems vacuum tight then I realized my error if you recall I tested the pump earlier and verified that it went down to 10 millor however I didn't check that it stayed that low you see when a pump is cold the oil viscosity is high and so the thick oil inside can effectively seal tiny gaps as the pump runs the oil warms up and becomes more free flowing and suddenly any tiny gaps will start leaking now a new rotary pump would have such tight tolerances that the warm oil would still adequately seal everything this

pump however is over 40 years old and it's likely that it has some serious weight wear that is causing the leak now if we're lucky the wear is confined to this part here this is the rotary shaft seal it's a hard rubber or plastic bushing with a spring-loaded wiper inside that should seal the shaft perfectly I pulled it out and replaced it with a new seal however I saw no improvement I decided to disassemble the whole pump and replace all the sealing components I replaced the external oil seal and the gaskets but while I was

inspecting the inner workings I noticed two problems first the shaft clearly has a huge Groove in it from 30 years of wear well that's not great and isn't really something I can fix easily I also decided to inspect the veins the critical ceiling component of a rotary pump I ended up having to take the whole pump apart just to check them out unfortunately these were badly pitted I bet you this pump got a little water contamination and then sat for years I went ahead and put the whole thing back together but again I saw no

improvement now I would definitely like to make this pump work in the future but at this point I'd already spent quite a while failing to fix it and so I decided to just replace the pump with a similar unit this is a Varan sd90 and it's probably about 20 years old itself but critically it's still in good condition and is able to pull a vacuum of about 6 millor which is excellent I used my lathe to build an adapter from the vacuum pump's kf25 output to a 24 mm hose barb to match the rest of

the tubing and connected it to my SC this time when I turned everything on I watched as the pressure dropped well below the 200 mitor from before all the way down to about 20 millor finally the vacuum leak has been solved and we can move on now that we know the system is not leaking it's finally safe to run the diffusion pump this pump needs cooling water to circulate through these tubes or else it will overheat fortunately I was able to scr up a small Chiller unit that should be just enough to keep this thing

cool I hooked up the tubing and verified that nothing was leaking after about 20 minutes the pump was hot and the Machine automatically switched modes from DP weight to pre Evac this is where the SCM uses the rotary pump to evacuate the chamber before it switches to the diffusion pump around about 50 millor once it reaches that point it will open the valve and use the diffusion pump to take it all the way down to a high vacuum about 0 .05 milor around a thousand times better than the rotary pump alone I waited for the

pressure to drop and yes the system correctly switched over right around the 50 milor Mark as expected but wait oh no we've got a problem the second valve is stuck and won't open well honestly what did I expect these valves probably haven't been serviced in at least 20 years looks like it's time for some much needed lubrication I powered down the SCM and waited until the diffusion pump was back at room temperature then I proceeded to tear down the entire vacuum system the two large valves near the column are responsible for switching between the rotary

pump diffusion pump and venting the chamber I slowly and methodically took everything apart and cleaned the valves with acetone and isopropanol to remove all the 30-year-old residual Gunk then I lubricated all of the moving or sealing surfaces using apas on L High vacuum grease just a side note you cannot use regular greases or oils in a high vacuum system because they will boil at low pressures and contaminate your system this is why lubricants designed for vacuum are so expensive a tube of apas on L the size of a travel toothpaste is a couple1 and there's

really no alternative now if you are in the no you might be saying what about Dow Corning High vacuum grease this stuff is 10 times less expensive only about $40 for a much larger amount however the problem is that this grease contains a bunch of silica which is abrasive it's great for static seals in a high vacuum system but it is unsuitable for any moving Parts because the abrase of silica would rapidly cause wear fortunately rather than purchasing the apis on L myself I was gifted a couple of CC's by Martin the other JSM 5200

owner who happened to have a tube himself Thanks Martin since the vacuum system is apart already I'm also going to recondition the RP vent valve this small valve on the bottom is a protection valve that isolates the entire sem from the roughing pump this protects the diffusion pump from atmospheric pressure in case a power outage or other failure causes the rotary pump to stop working same as before I cleaned it with acetone and isopropanol and lubed it with apas on L grease after a marathon lubrication session I managed to reassemble all the valves and get

everything reinstalled on the SC boy was that a lot of effort let's see if it paid off and success the valve is no longer stuck now we can see if the diffusion pump is working well look at that the pressure is plummeting I was certain that I'd have to replace the oil in the diffusion pump but it looks like the pump is operating just fine after a couple of minutes it reached a pressure of about 1 to the4 millor which is about 500 times lower than what it was in the pre- Evac mode this is

well into the high vacuum region and is an acceptable pressure for running the machine awesome now that the vacuum system is working it's time to see if the machine is functional let's turn on the high voltage okay that's a good sign the CRT is on which is excellent this means the high voltage Supply is functioning let's turn on the electron gun now this is the knob that controls the current that heats the tungsten filament you can see that as I turn up the knob the filament current increases which is a good sign that that means

that the filament is intact according to the manual we want to turn this up until the current is between 40 and 50 microamps we also want to make sure that we don't go too high and blow the filament I carefully turned up the current until I reached an approximately correct operating Point hm I feel like I see a difference on the screen but I don't know I don't see anything in particular let's see if fiddling with the knobs helps at all well the contrast knob doesn't seem to do anything at all which is a bad

sign the contrast knob controls the voltage on the photo multiplier tube which is the main electron sensor and what is actually producing the image even if the electron gun isn't working at all cranking up the contrast should at least amplify a bunch of noise and make the screen all grainy let's take a look under the hood oh wow that is quite a mess I looked through the schematics and it's clear that this board here is an aftermarket part it's actually a board that allows this early 1990s microscope to interact with this box which can send

images to a computer so basically this board intercepts the video signal and reroutes it through this cable which goes back to the original board wait a minute check out this RCA cable doesn't that look a bit damaged I bet you that in the process of modifying this scope the cable ended up getting into a bad orientation and got kinked when this door hinged closed yep that is one broken cable fortunately I have a replacement looks like my cable hoarding comes in handy for once I'm not sure when was the last time I used one of

these to carry an actual video signal ooh that's looking a lot better let's see what happens when I fiddle with the knobs this time okay this is a good sign the contrast is definitely doing something now this is a good indication that the signal path for the detector is actually working brightness seems to work as well but are actually Imaging anything or is this just errant electrical signals the focus buttons don't seem to be doing anything this might indicate some issue with the circuitry that drives the electron lenses how about the magnification buttons hm these

also don't seem to be doing anything hang on a sec oh wow the buttons clearly aren't working I connected my om meter to the terminals and pressing the buttons does nothing maybe the contacts got corroded let's remove them and see if they can be repaired or replaced now normally I would use a soldering iron and solder Wick but this is a pretty high stakes operation and I do not want to risk ruining this board fortunately a friend lent me this fancy desoldering gun and I've got to say I really need one of these this thing

made easy work of removing the switches so now that I've got them out let's disassemble one of the switches okay this is really interesting I thought for sure these were mechanical switches but actually the switch mechanism inside is just a simple membrane switch I actually thought this microscope predated membrane switches well easy enough I guess we just need to replace the membranes I happen to have this old Xbox controller that I don't use anymore so it's going to become an organ donor for my sem luckily I only need four membranes and it looks like the

membranes on these keys are just about the right size to replace the originals I just need to carefully cut them out since they are all fused together okay that looks good let's reassemble the switch and see if that fixes it success well that's awesome I fixed the other switches in the same way okay time to solder the switches back in by the way I did fully power down the unit before doing this just in case you worried okay everything is back together let's see if I can change the magnification now okay well the LCD at

least says the magnification is changing but I don't really see any on the screen well actually when I zoom all the way out it does look like something maybe wait a minute that Circle might be the center of the specimen stage inside the chamber hang on a second let's move the stage and see if anything moves on the screen okay I think that might be the stage on the screen it looks like it moves as I twist the micrometer knobs okay well that's definitely promising what if we zoom in a bit let's see if we

can focus the microscope hey that's more like it it looks like the image is coming into Focus this is fantastic I'll be honest when I first got this machine I did not expect to get this far it looks like our repairs have actually succeeded this machine is actually working and producing images of reasonable quality I cannot express how happy I am that this machine is working I know this video has been brief but in reality this whole repair process has taken many months and at several points during the process I thought all hope was lost

it is extremely satisfying to see this whole project finally coming together like this now obviously there are still problems that need to be fixed I noticed that there are some issues with the stability of the video signal which will probably require identifying and replacing some of the components on the amplifier boards there are also some issues with some relays sometimes when you change the magnification the image goes all wonky and then it's fixed when you cycle the relays again however now that the machine is operating I just have to image something I have this integrated

circuit with exposed wiring and I want to look at the wire bonds that connect the external legs of the IC to the internal silicon chip this is accomplished with a machine called a wire bond which Heats and vibrates a tiny gold wire and smooshes it against the Silicon surface forming these mushroom shaped pads you can see that some of the pads are well formed While others appear to be misshapen but are still functional another amusing thing about integrated circuits is that occasionally the designers will have a little extra space on the silicon and some designers

will use that tiny space and write messages or graffiti you can see that this designer wrote go cards right here I'm not exactly sure who the cards are but I'm assuming it's a sports team somewhere I also found this dead fly and put it in the microscope as well normally you need to coat non-conducting specimens in metal for proper Imaging but as it turns out you can still get a half decent image if you tweak the settings correctly in this case I turn the accelerating voltage down from 25 kts to about 10 KS check it

out here's the fly under the electron microscope if we zoom in we can see the individual hexagons of its compound eyes pretty cool now you might be wondering why is the image so grainy well fortunately that can be fixed this is a circle of copper that's 3 mm in diameter with a very fine Square pattern now here it is under the electron microscope as I adjust the position it should be obvious that the frame rate is really high this is nice because it makes it easy to see what you're doing in real time the downside

though is that the beam is scanning across the surface incredibly quickly because of this the electron detector only has a very brief moment to capture the data for each pixel this results in a very grainy image fortunately we can slow down the scan rate this mode slows the scan rate down to about 1 frame per second it also displays some useful information on the screen as well it's a little hard to tell the difference so let me zoom in a bit this is a closeup in the fast scan mode now watch what happens when I

slow down the scan Rate Check out how crisp those edges are now most of the highquality images taken by electron microscopes are done using an extremely slow scan mode often around 1 minute per image to extract the maximum detail speaking of detail I was curious to determine the maximum resolution of this microscope to do that I needed to find something with an extremely small feature size I found some traces on my chip that were covered in this extremely fine particulate at 1,00 times magnification the limit of an optical microscope you can just barely make it

out if we zoom in further it becomes super obvious that this layer isn't smooth at all but is instead made up of tiny little particles let me enable slow scan and bring up the measurement bar you can see that these particles are about 1 to 5 microm in diameter let me find a really small one and zoom in more here we are at a 100,000 times magnification this particle is about 2 or 300 nanom wide those wavy edges are actually caused by vibrations which is something I'll need to reduce if I want to improve the

resolution further by by the way remember the computer that I showed earlier I did actually manage to get it working well sort of it comes with software that allows you to capture images directly off of the microscope here are those grains from earlier now this thing definitely needs some work it's got some pretty serious signal Integrity issues but I did manage to capture a few good still images here are those small particles again this is the highest resolution image I was able to get so where do we go from here well well obviously there is

still more work to be done there are some components on the machine that still aren't working optimally and need to be replaced however the most pressing thing for me is to find out what I can actually do with this machine this is probably going to be the subject of the next video and to do that I need to accurately determine its resolution after that I should be able to start using the machine to help me develop semiconductors in future videos now I just want to make it completely clear it is not necessary to have a

scanning electron microscope to make semiconductors at home an optical microscope is usually more than enough however now that I have it I will definitely be leveraging this sem for future semiconductor development in addition I'd like to get input from you the viewers of the channel on what I should do with this sem would you like to see more detailed videos of how electron microscopes work do you want to send me things to look at feel free to let me know in the comments if you have any ideas in the meantime I want to thank you

for for watching I honestly didn't know if I would ever be able to make this video and I really appreciate everyone who stuck around I also want to thank my patrons on patreon as well as the members of the sem Discord channel for all of their encouragement and advice especially Martin did Shadow and monochroma I couldn't have done this without all of your help thank you and I'll see you next time

Related Videos

26:23

I Built the Secret "Death Ray" from 1923

Turnah81

122,121 views

27:10

Smallest 4K 120fps Camera Possible

BPS.space

280,475 views

24:52

Sony's Breakthrough Color TV

Asianometry

342,790 views

34:49

People said this experiment was impossible...

Veritasium

6,356,272 views

27:44

How many plants do you need to breathe? T...

Joel Creates

3,998,899 views

23:40

50,000,000x Magnification

AlphaPhoenix

5,673,641 views

15:51

I Built The First LAMINAR FLOW ROCKET ENGINE

Integza

3,341,653 views

14:41

LASER Headlamp for Cars?!? How strong is i...

Brainiac75

35,529 views

1:00:15

I bought a freeze dryer so you don't have to

Technology Connections

1,994,193 views

16:57

Creating an Exotic Material With A Static ...

Plasma Channel

430,615 views

43:36

Making the stinkiest chemical known to man

NileRed

14,350,014 views

16:50

If it Looks Right, It Will Fly Right - Rig...

Curious Droid

228,601 views

16:05

I made a fake CRT TV with a LASER

bitluni

387,428 views

22:26

Can Intel survive the valley of death?

TechAltar

216,663 views

46:07

Speedrunning 30yrs of lithography technology

Breaking Taps

897,168 views

33:03

Why Some Designs Are Impossible to Improve...

Design Theory

2,260,671 views

15:57

This tiny computer changes EVERYTHING

Jeff Geerling

553,028 views

16:44

How SpaceX Reinvented The Rocket Engine!

The Space Race

1,659,718 views

25:54

My New Satellite Can Take Your Selfie From...

Mark Rober

4,268,297 views

33:52

This G15 is the Oldest Running Digital Com...

Usagi Electric

134,081 views