Supply Chain Management - Cadeia de suprimento - Supply Chain Certifications

108.75k views1220 WordsCopy TextShare

ISCEA - Supply Chain Journal

https://www.isceaonline.com

Versão legendado per ISCEA do vídeo criado pela Universidade do Arizona...

Video Transcript:

welcome to Supply Chain management now I know most of you have spent your childhood evenings dreaming of taking your first Supply Chain management course but for those handful of you who might not know what Supply Chain management is let me provide you a brief explanation let's take a simple product like a bottle of water clean water a plastic bottle a plastic cap and a label buying them at the store or vending machine might cost you about $150 how much of that do you think is profit nope wrong wrong again not likely water a plastic bottle

and a label That Couldn't cost more than 50 cents and if you buy them in bulk how could each bottle not give you at least a dollar in profit seriously if you think you can make $1 per bottle you should drop out of college right now and get into the bottled water business you see this right here illustrates one of the most common consumer misconceptions product cost is not equal to material cost and in business you don't have the luxury of thinking only as a consumer you need to think like a business executive or better

yet an entrepreneur so in order to figure out where all that profit went we need to imagine what it took for that bottle of water to get into your hands first you need to negotiate the purchase of the empty bottles and caps those bottles will be much easier to transport if they're in boxes we'll need to shrink wrap those bottles so they don't fall out of the box we can move a whole lot of boxes quickly if they're all put on pallets in order to move the pallets you'll need a forklift which means you'll need

a forklift driver that forklift will then take the pallet and put it into a truck which will require a truck driver Fuel and insurance also you'll need a label for that bottle of water therefore you need to design the label print the label and get the label shipped to the plant another truck driver more fuel and insurance our water bottling plant won't be free and neither will the energy it uses in our bottling plant we'll have employees and bottling machines and let's not forget the day-to-day items like light bulbs garbage bags machine parts janitorial supplies

toilet paper and anything else that will be used at the plant by the employees oh yeah and we'll also need access to the drinking water machines will then purify the water other machines will bottle the water and affix the labels to the bottles and still another set of machines will box shrink wrap and then palletize the bottles in order to move those pallets again you'll need a forklift which means we'll need another forklift driver that forklift will then take the pallets and put them into trucks head it to the distribution centers and and as we've

seen those trucks will require drivers Fuel and insurance those distribution centers will also require employees forklifts and energy from the Distribution Center they'll head out to retail stores on still another truck which will require a driver Fuel and insurance that store will need employees to unload the truck stock the bottles of water on the shelf or refrigerator if you have a refrigerator you'll of course need energy if we want a secure our stock we may get a security guard or a security system and of course the store will likely get insurance also Imagine the cost

associated with returning and replacing bottles that are damaged oh and for some reason even bottles of water sometimes have 1800 numbers which means you'll need a staffed call center to answer the customer questions about your bottle of water wow all those materials boxes people machines buildings energy Fuel and vehicles they cost money those things weren't free and they probably weren't used efficiently and it's likely that several bottles didn't survive the journey to the consumer oh and by the way the employees at the water company you know the ones that work in finance accounting marketing human

resources and it they want a paycheck too so through that simple example of a super simple product we're beginning to see that companies face challenges when they buy things make make things move things sell things and service things which includes repair and maintenance oh and let's not forget companies need to do all these things using sustainable materials energy and methods guess whose job it is to make sure that all these things happen flawlessly with minimal effort and of course at minimal cost you guessed it supply chain managers the supply chain manager needs to be able

to do all of these things they need to give the customer the product they want when they want it as often as they want it for a reasonable price while still managing to make a profit this requires worldclass skills and knowledge in the study of Supply Chain management there's that scary term again Supply Chain management let me try to make it friendlier by shuffling around the words there you go the management of the chain of supplies for some reason that just seems a whole lot easier to understand doesn't it but it also helps us understand

the complex nature of Supply Chain management I mean the management of the chain of supplies now let's think of other products and what their supply chains might Encompass hamburgers sweaters coffee tables cars and airplanes now I know many of you are saying but I live in a service economy I won't be manufactur in anything wrong again as of 2008 the US was still the number one exporter of manufactured goods okay maybe not for long so let's talk about service Economy Supply chains let's think of something you're probably familiar with the hotel industry what do hotels

manufacture lodging experiences dining experiences Spa experiences which altogether make up vacation and Conference experiences in order to do all all these things effectively and efficiently what's required hotels need to buy things like beds furniture televisions cable food soaps towels they also make things or in this case manufacture services like housekeeping meals massages and special events hotels also move things like transporting clean towels and food to and from the rooms as well as transporting guests and their luggage to and from the airport they even sell things like in room movies internet services and tickets to events

and finally they also provide services such as making reservations organizing events making wakeup calls and even cleaning and pressing clothes once again we see that the fundamental skills learned in Supply Chain management can be used to manufacture service experiences as much as they aid in manufacturing products well I hope that this has given you an idea of what Supply Chain management is all about you see this is the reason why little kids all around the world want to be supply chain managers they want to take part in manufacturing the best products and services on Earth

so again welcome to Supply Chain management where all of your childhood supply chain dreams are about to come true

Related Videos

43:04

Understanding Inventory Management (INSIDE...

MVC Logistics Academy

65,027 views

10:45

Explained Supply Chain Management in 10 Mi...

Leaders Talk

115,649 views

25:45

O QUE É CADEIA DE SUPRIMENTOS?!

Quadrivium Academic

274,108 views

13:56

Evolução da Logística

Thiago Fagner Dekster

281,910 views

1:37

Certified Supply Chain Analytics Professio...

Chartered Institute of Professional Certifications

2,548 views

11:03

How to Fix Broken Supply Chains | Dustin B...

TED

108,772 views

4:46

A Importância das Cadeias de Suprimentos -...

FGV EAESP Pesquisa

25,134 views

7:10

WMS - Sistema de Gerenciamento de Armazém

lelopesrock

156,153 views

33:06

Morning Coffee ☕ Happy Music to Start Your...

Sensual Musique

15,813,406 views

12:03

SUPPLY CHAIN - Tudo sobre CADEIA DE SUPRIM...

Ser Logístico

194,352 views

15:24

Problemas da logística brasileira

Edu Gonzaga

157,210 views

1:17:36

Google, the giant that wants to change the...

Investigations et Enquêtes

444,342 views

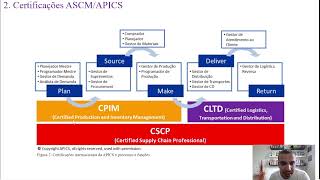

20:41

Certificações APICS ASCM - CPIM, CSCP, CLTD

EPCS Educação Profissional Cadeia de Suprimentos

926 views

1:20:20

What is Procurement?

CIPS

226,049 views

4:46

What is LOGISTICS?

Engenharia Detalhada

417,224 views

10:31

One of the Greatest Speeches Ever | Steve ...

Motivation Ark

35,471,156 views

7:11

O QUE É SUPPLY CHAIN? (O Que É Cadeia de S...

Blog Abri Minha Empresa

120,991 views

19:06

Calculus at a Fifth Grade Level

Lukey B. The Physics G

7,997,333 views

50:34

CADEIA DE SUPRIMENTOS: Conceito, importânc...

SAC Logística

18,022 views

1:29:58

Best classical music. Music for the soul: ...

Largo Classics

902,255 views