O que é SILÍCIO? Segredos do SILÍCIO: Da Rocha à Eletrônica. Desvendando o SILÍCIO da Engeharia

112.9k views1497 WordsCopy TextShare

Engenharia Detalhada

❗❗❗ Seja membro deste canal e ganhe benefícios:

https://www.youtube.com/channel/UCAaD-P-PxAkKS5WX8Ep...

Video Transcript:

What is Silicon? Hey Engineering Lovers, today we're going to talk about a component that you're probably using right now. Whether it's your TV, your tablet, your computer, or your phone, much of the electronics in that device contain silicon.

But what is Silicon? Before telling you about the silicon, take the opportunity to subscribe if you are not already subscribed, leave your like, and activate the notification bell and if you find our content interesting, consider becoming a member to help us continue producing content here on the platform and be remembered in our videos. Silicon is a chemical element that belongs to the semiconductor family in the periodic table.

It is denoted by the symbol Si and has the atomic number 14. Silicon atoms have four electrons in the valence shell, the outermost shell of electrons. They share these electrons with other atoms, forming covalent bonds.

Covalent bonds occur when atoms share electrons to fill their valence shells and achieve greater stability. When many silicon atoms join together through covalent bonds, they form a three-dimensional crystalline structure. This results in a solid material that is highly ordered in terms of its atomic arrangement.

This crystalline structure is one of the reasons silicon is so valuable in the electronics industry, as it provides a highly controlled environment for conducting electrons. But don't worry, this is getting too chemical, let's start from scratch. When was silicon discovered?

It was discovered in the early 19th century and its discovery and isolation were the result of a joint effort by several scientists over time. Antoine Lavoisier, a French chemist, observed in 1787 that silicon dioxide, which we more commonly know as silica, was a compound and not an element. In 1823, Swedish chemist Jöns Jacob Berzelius managed to isolate silicon for the first time, heating silicon chloride (SiCl4) with metallic potassium, obtaining silicon in impure form.

Berzelius named the element "silicon", derived from the Latin term "silex", meaning stone or rock. However, silicon was not yet well understood, and its purification and detailed properties were studied over time. With the evolution of chemistry and metallurgy, it became possible to produce high purity silicon, which was fundamental for its use in the electronics industry, which developed in the 20th century .

Today, silicon is an element widely used in electronics and various other industrial applications due to its semiconductor properties and its abundance in the Earth's crust. And where is it found? It can be found in various natural sources and materials.

One of the most common sources is quartz, which is the most abundant form of silica (SiO2) and is present in many rocks and minerals. Sand, which is mainly composed of quartz grains, is also a rich source of silicon. Additionally, silicon is present in other minerals and rocks, such as granite and marble.

It is released into soil by the decomposition of silicon-containing minerals and can be found in many types of soil. Plants absorb silicon from the soil and incorporate it into their structures, and some accumulate silicon in their cells to increase their resistance to environmental stress. Silicates, which are common minerals, also contain silicon, including minerals such as feldspar, mica, and clay.

In the electronics industry, silicon is artificially produced in its purest form and is used in the manufacture of computer chips, transistors, and other semiconductor devices. Additionally, glass is manufactured from quartz sand, making it one of the most well-known applications of silicon in industry. This wide availability of silicon in nature, along with its unique properties, makes it a crucial element in several industrial and technological applications.

And how is silicon mining and processing done? These processes involve several steps, from extracting raw silicon from nature to obtaining high-purity silicon suitable for electronic and industrial. Mining begins with the extraction of quartz, for example , which is one of the most common sources of silicon, which can be found in the form of crystals or in large veins in underground or open-pit mines.

The raw quartz is then broken and ground into smaller pieces to facilitate transportation and further processing. The silicon extracted from quartz is not pure enough for electronic applications, so the next step is to purify the material. This is usually done through a process called the "Siemens process," which involves reducing silicon with a reducing agent, such as carbon, at a high temperature.

This produces silicon metal, but it is still not pure enough. The resulting silicon metal is refined several times to remove impurities. A common method is the zoned refining process, where a heater is passed through the raw silicon several times to separate impurities and obtain higher purity silicon.

This purified silicon is then melted and slowly cooled to form single-crystalline silicon crystals. This is a critical step towards manufacturing what we call silicon wafers used in the semiconductor industry. These wafers are made by cutting thin layers of monocrystalline silicon crystals, which are then polished to have a flat, smooth surface.

To manufacture electronic devices, silicon wafers are doped with other elements, such as boron or phosphorus, to change their electrical properties. The doped wafers are processed to create complex electronic circuits such as transistors, diodes and computer chips. This involves photolithography, layer deposition, selective etching and several other processes.

After manufacturing, silicon chips are tested for function and then assembled into electronic devices such as computers, smartphones, home appliances, and more. It is important to note that silicon processing may vary depending on the specific application. The electronics industry requires extremely high levels of purity, while other applications, such as glass manufacturing, can handle less pure silicon.

And why is it a semiconductor? This has to do with a step we mentioned previously, which is doping. One of the most important properties of silicon is its ability to be "doped".

But don't worry, we're not going to put any drugs in the silicon. (put a meme here) Doping means that we can introduce small amounts of other elements into the silicon structure. For example, by adding phosphorus atoms to silicon, we create a silicon that we call "type N", which becomes more conductive, that is, it conducts electricity more easily.

On the other hand, by adding boron atoms, we obtain "P-type" silicon, which is less conductive. This doping capacity is fundamental for the manufacture of transistors and other electronic devices. Due to its crystalline structure and controlled doping capacity, silicon is classified as a semiconductor material.

This means that it can conduct electricity intermediately between conductors and insulators. For example, silicon transistors are the basic building blocks of modern electronic circuits, and they act as electronically controlled switches that can turn electrical current on or off as if they were switches. And where is silicon actually used?

The most prominent use of silicon in engineering is in the manufacture of electronic devices. Silicon chips, also known as integrated circuits or microchips, are the basis of computers, smartphones, tablets and a wide range of electronic devices. Silicon is used to create transistors, diodes and other electronic components on microscopic scales.

Crystalline silicon is the most common material for the production of photovoltaic solar cells. Silicon solar cells convert sunlight into electricity efficiently and are widely used in solar power systems to generate clean , renewable electricity. It can also be used in power electronics to control and convert energy electrical in applications such as inverters, rectifier systems and variable frequency converters .

In addition to high-power devices, silicon is also used in microelectronics, which involves manufacturing microscopic components such as sensors and microelectromechanical systems called MEM. These components are widely used in medical devices, environmental sensors, industrial automation, and more. It is also used in refractory materials, which have high heat resistance and are used in furnaces, furnaces and high temperature applications in industries such as metallurgy and glass.

And not just in furnaces, but in the glass itself, where silicon is widely used in the manufacture of glass, which is essential in construction and many other applications, such as windows, lenses and solar panels. These are just some of the main applications of silicon in engineering. Its versatility as a semiconductor material and its physical properties make it a fundamental element in a wide variety of industrial and technological sectors.

So, did you know all these interesting facts about silicon? Did you know that its structure can be modified to suit different types of applications? Can you imagine the amount of silicon inside your cell phone?

Leave it here in the comments and I want to know. Here you have two video options that you might like and that are worth checking out to continue following our content. And if you want to contribute to us, leave your like, subscribe to the channel and consider becoming a channel member so we can keep our content alive.

Related Videos

13:34

What is CERAMICS? What are the characteris...

Engenharia Detalhada

24,143 views

27:14

Entramos na USINA NUCLEAR de ANGRA!!! #Boravê

Manual do Mundo

6,446,017 views

1:00:57

Discussing Intel's New Place In The GPU Ma...

PCWorld

1,092 views

19:35

How Carbon Nanotubes Will Change the World

Real Engineering

2,056,992 views

12:47

What is KEVLAR? How is KEVLAR made? Why is...

Engenharia Detalhada

79,361 views

25:27

How Japanese Masters Turn Sand Into Swords

Veritasium

13,971,903 views

11:26

What is ALUMINUM? Why is ALUMINUM used so ...

Engenharia Detalhada

218,984 views

33:45

Why It Was Almost Impossible to Make the B...

Veritasium

28,448,226 views

2:27:57

Lucky Bhaskar full movie hindi doubed || S...

Md Yajul Vlogs

1,228,920 views

27:48

How are Microchips Made? 🖥️🛠️ CPU Manufa...

Branch Education

6,031,168 views

20:50

Is it the volts or amps that kill?

styropyro

4,958,927 views

19:13

Cutting mirrors with Diamonds

Breaking Taps

1,338,981 views

10:15

What is URANIUM? Uranium: From Mining to E...

Engenharia Detalhada

927,088 views

19:26

How did the Enigma Machine work?

Jared Owen

10,569,834 views

19:22

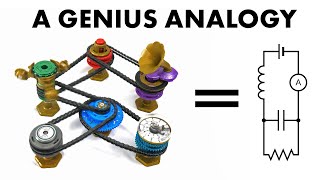

Mechanical circuits: electronics without e...

Steve Mould

7,362,949 views

11:28

What is DIAMOND? How is DIAMOND found? Dis...

Engenharia Detalhada

106,407 views

17:53

The Insane Engineering of MRI Machines

Real Engineering

3,215,464 views

27:43

Adani | ₹2000 Crore Bribery Case EXPOSED |...

Dhruv Rathee

7,802,535 views

2:27:57

LUCKY BASKAR FULL MOVIE #luckybhaskarmovie

all_team

7,450,416 views

18:20

Transístor Explicado - Como funcionam os t...

Mentalidade De Engenharia

1,298,016 views