1,000HP RB26 Engine Build - Full Start to Finish [4K]

989.61k views7619 WordsCopy TextShare

throtl

Check out our engine build episodes:

600HP SR20DET: https://youtu.be/TvqgprMMn8g

1,100HP 2JZGTE: htt...

Video Transcript:

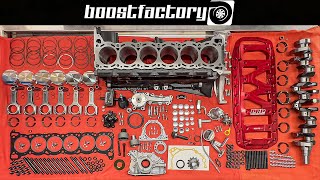

we are building an rb26 with a ton of aftermarket parts this build is going to be absolutely insane so let's get to it what is going on guys welcome back to the throttle YouTube channel my name is Quinn and I'm here with Mickey and we have an rb26 we're going to be building in today's video look at this beautiful block what do we got going on here Ricky it is quite beautiful so this is a prepped block from our friends over at Platinum Racing Products over in Australia this is not actually an rb26 block this is actually an rb25 block we were able to get a block that was very uniform and they were able to machine it so that we've got very consistent walls in here the block is beautiful and we can sit here and talk about it all day there's a heap of Parts back here on the table so let's go through what we have here and explain to you guys kind of what the direction of this build and what it's going to be when it's done now before we show you guys the parts we're going to be using on this rb26 I want to talk about the engine what we're going to be using this is very special engine oil by Mo tool you guys know we love our Mo tool this is actually a Nismo competition well developed by motul with the help of Nissan and it's going to be perfect for this rb26 this engine oil is going to be perfect under the high storm conditions that this RB 26 is going to see a lot of power a lot of boost a lot of high RP p. m this engine oil is going to be very composed and it's not going to break down or fail and it's going to allow this rb26 to run at really high power whether on the dyno or on a track so let's get into the parts we're going to be using starting with our short block table we have pretty much all the lower end stuff here we have a set of Italian RP pistons and connecting rods I've never used them before interested to see how their products come together we have a set of ACL race Main and rod bearings going to be going in as well as a platinum Racing Products oil pump and it solves a lot of the oil pump issues that these RB engines have of course we have the crankshaft which is fitted with the spline drive so this is a stock every 26 crank just fitted to fit the oil pump which is really cool we also have the PRP brace here so this is the pretty much the engine cradle brace so this is going to stiffen up the block and it's going to allow us to run the four wheel drive oil pan and get that thing set up which is really cool love to see it it's unfortunate it's going to be buried in the bottom of the engine we have a new water pump and pretty much all the accessory and all the little things on the engine are going to be brand new such as the lower timing cover rear main seal housings just all the little stuff like that it's just nice to have new so remember a full set of Grady pulleys all the way around PRP sent us pretty much every single Nut and Bolt from the entire engine which is really cool so we have titanium Hardwares everywhere and then this is the hardware pack for the brace as well so we have a lace spec oil pan here so Mickey actually sent this out to Stuart and he went through and did it so the theme to with rb26s is oiling is concerned is leave the entire thing stock or go full bore and do literally everything so that's what we're doing here we sent this out he added a lot of capacity a lot of engine oil volume to this panel added some internal baffling so this thing is ready for some high power and they rebuilt the diff and it looks freaking beautiful really nice piece and here's our trigger kit for the crank moving on to the top end table we got some really nice pieces here starting off with the greddy cylinder head package for the rb26 so this is a recently new thing for Grady which is really cool they're doing upgraded heads this thing is an absolute monster looks brand new beautiful valving the intake ports on the side are insane it's such a nice looking cylinder head it's going to low really well this one is also set for a very high lift hydration cam which is supplied by GSC power division that's part of the cylinder head package so this thing is going to flow extremely well we have a set of grated cam gears going along with it this is another piece by Platinum Racing Products so this is a cylinder head drain kit for the rb26 so this is going to pull extra oil and coolant out of the cylinder head this is going to give everything another place to go and drain out we have a full set of itbs that have been completely refreshed by Ian from remade in USA this thing literally looks brand new all the hardware has been taken apart and coated as Mickey wanted everything to be coated so nice they did all the little clamps touches it's such a nice piece and of course it's fitted with a Grady and fuel rail we have a Grady intake plenum just to top the whole gratty head package out and here we have our PRP cam trigger kit so we're going to be running these this is the exact same kit we used on the airb20 work really well and then we have full titanium hardware for pretty much the entire engine by Platinum bracing products so these are for the cam studs we have some for the intake manifold as well as the water pump and the oil pump and pretty much everything else moving on to the Turbo System we have an rtek manifold we have an r-tech manifold on their Supra we absolutely love it we had one on our gtst it was such a nice piece we thought we'd bring it back and it looks absolutely beautiful we're going to pair that with a G35 900 turbocharger and a 45 millimeter turbosmart wastegate we do have a ton of other parts going on this engine this was just kind of the main ones to get it done this is pretty cool this is a competition oil cap by motool which is a really nice touch and then we have a Grady timing belt all the timing components literally everything in this engine is going to be brand new the only few things that are missing that are not on the table are the valve covers they have not arrived yet but I think we can get started without them so I'm very excited to get this rb26 engine build starter we have a lot of really top tier Parts going on to this engine so let's get into it yes [Music] we're going to start our engine build off with the crankshaft going into the block now this block has been line honed with ARP Hardware in it so we should have absolutely zero problems with inspecting our main bearings and the crankshaft itself is in really good condition so we're going to put everything together make sure that we're still good just always good to do a double check and then install the crankshaft for the final time get our oil pump and a rear main seal on if you haven't already make sure to subscribe to the throttle YouTube channel and turn on the Bell notifications so you don't miss a thing [Music] foreign [Music] [Music] we just got our Mains in and checked and they're a little tighter than I'd like them to be so I think we have a set of oversized bearings that we're going to drop in and see how the clearance changes plastic gauge is kind of a rough and dirty way to check what your bearing clearances are now this engine has been out to machine shop so honestly everything should be absolutely perfect but I like to do a double check and that's why we use plastic gauge so typically we'll go for a sparing spec which is what we're at we're a little bit tight so we're going to throw in some of the oversized bearings to see if we can get it to loosen up a little bit and then we'll check them again make sure they're good typically engines that I'll send out to the machine shop that they're doing all this stuff when they inspect the crank they're miking it they're miking this checking the main hone or the main Journal where the crankshaft will actually sit and speccing that out so they handed it to us we really don't have any reason to suspect it being bad that's why I use plastic age if I'm assembling an engine that I've never done before and like a block isn't going out to machine shop then we'll bust out the mics and make sure everything's good and plastic gauge isn't as accurate as you really want it to be but it's a really good way to check that everything is so good so we're going to take these out put our oversized bearings in loosen up that clearance just a little bit and then double check [Music] we're good now our standard size bearings were a little bit too tight but the oversized bearings work just fine so these ones have a little bit extra oil clearance which is good so when we're flowing and going fast with this thing we're not going to have any oil pressure issues from the main so we're going to clean all this stuff off I'm going to actually put this back down measure and play so the forward and backward movement of the cranks see where we're at and then if we're good there we're gonna take it all apart Lube it clean it put it back together we'll be good to go our crankshaft has installed everything feels good we got all the right specs our run out is good so we're gonna go ahead and throw our rear main seal on we got a brand new one from Nissan and then Mickey's actually going to paint the back of the engine block this is the one part of the block that has not been painted because you couldn't get to it when the engine's on the stand so let's get this thing on [Music] foreign [Music] crankshaft is fully installed and thrust feels good everything is where we need it to be our Ruby and seal is installed and we're going to flip this block over our Gap and piston rings before we do that I got a little set of grub screws that are going to go into little galleries in the crankshaft and then we'll be done flip it over start capping our rings and uh I'm gonna throw you guys up on the tripod for that we'll get it done [Music] so right now I'm checking ring end Gap so what these are out of the box so the ring end Gap is a spec for the piston ring so how much play is in between the end of the ring so if you guys can see it has an opening on one end now the end Gap is important because having too much end Gap you'll have blow-by which is a lot of gas the combustion gas is going past the Piston down to the crankcase if you have too much it'll have a low compressional lens cylinder and that's not good and it'll have a lot of blow by if you're too tight what will happen is if the engine gets hot or leans out or is running too much boost the ring will expand if the ends will touch and then it'll expand further and the ring will go up or go down and break Pistons so it's very crucial to get the ring end Gap correct we're going to be running the ring end Gap spec that they run over in Australia because they do a lot of RB engines here typically you'll get a worksheet on the set of Pistons so like cast piss and enforgeous and a different ring in gaps so we're going to go with the specs that these guys gave us because they're really good at building herpes and they do it a lot so let's get this thing together foreign [Music] done so we set it at 19. if we get the 19 in there got a nice little bit of drag so it has a little bit of resistance if I grab a 20 it fits but it's got some more pull and if I go for a 21 it barely fits and if I pull on it it like lifts the ring out so we're at about 19th out which is perfect that's our top ring spec so we're going to set our second compression ring to 21 and then this cylinder will be done oh [Music] our piston rings are all sorted everything is good so now we're going to start assembling our piston and connecting rod and then we're going to put the rings on it get this block back on the stand and start dropping these in so this is an Italian RP connecting rod and we're going to be using Pistons by Italian RP I've never used a rotating assembly by them before so I'd be curious to see how it all comes together and if we like it or not so first thing we're going to do is just a quick inspection make sure everything looks good on it I always like to inspect all the new parts as we get it to make sure that there are no errors in manufacturing or anything like that you have a wrist bin here so I'm going to check to make sure that everything slides nice some connecting rod sets I've gotten have had little Burrs in the bushing here so this is actually a press fit bushing on the end of the connecting rod sometimes you'll have a little Burr and you'll have the wrist pin not sliding nice through so it'll like get to the end it'll get stuck and if that happens you just got to take a little piece of sandpaper and file the program so in this case Everything feels good slides nice through we're gonna do the same thing with the Piston make sure it slides through the Piston nice which it does so like all the other forged pistons we have a set of circlips here so the circlip is going to go in the little Ridge on the inside and we're going to pop that down we're going to put our wrist pin through there and we're going to orient the rods accordingly so on this piston you'll see the recess for the intake valves are a lot bigger than the recesses for the exhaust valve so these are directional Pistons this is the intake side there's the exhaust side and I'm going to put our little bearing tangs on the intake side so that's going to be our orientation essentially I hope got it backwards essentially like that so we're going to start putting our circlips in Lube everything in the wrist pin get that all set up once I get our second pin in here we'll be done we're going to assemble all six then we're going to throw piston rings on here then into the block they go [Music] there's one done we got five more to go then we'll start throwing them in the engine [Music] thank you [Music] crystals are reassembled everything went together really nicely and they looked beautiful so I went ahead and numbered each piston so we got one and two now the Pistons and rods themselves aren't more specific but the Rings are so we got these rings for the board that they're going to be going into as soon as this ring set goes onto that piston this becomes cylinder one so I've got them all labeled out we're gonna throw our rings on and then get this block back on a stand start dropping a bit [Music] cylinder one is done [Music] these are ready to go in the engine before we put the engine block back on the stand I've got a set of oil Gallery plugs we have to install so when this block was disassembled for cleaning they took literally everything out all the freeze plugs these are brand new freeze plugs and then they drilled out a little press fit for the oil Gallery so they can clean this so this oil Gallery feeds a lot of things in the engine block and having that clean is essential so they've cleaned it they've tapped it so we can run some bugs in we're going to put these in get this thing back on the stand [Music] foreign [Music] dropping pistons in so we're gonna be doing one and six so we're going to take the rod caps off drop the rod bearing at each and then we're going to drop these into boards and then check our rod bearing clearance make sure everything's good and then final assembly cylinder one is cylinder section processor Pistons which means they share pretty much the same Journal orientation so these two Pistons are going up and down together all the time so we're going to do those and then five and two are also sister pistons and then three and four of the same so we're gonna go from the outside in and we'll have all our Pistons oh [Music] [Music] all right there's two in the hole Yeah foreign [Music] ERS one and six are in we're at bottom dead center we have the Pistons pushed all the way down and these are the bottom of the rods right here so I've laid some plastic Edge on the journal again we're going to be just like we did with the mains checking the bearing clearances now this crankshaft and this block have already been out the Machine Shop they've already inspected and measured everything and the rods are brand new and they've been measured at the factory so this is kind of like a double check just to make sure 100 that we're okay so we're gonna drop the rod caps on Titan this little piece of green right there which is like a circle when we compress it it's gonna get squished and then it'll get like nice and wide and then we'll measure how wide it is now if you have something that's really tight it's going to swish it more and it's going to get wider or if it doesn't get squished as much it's going to be narrower in that which dictates what our bearing clearance look like so on our paper here we have a little measuring so this is in thousands so you can see a lot of Squish really tight and as the clearance gets bigger as long as you get more clearance then the squish gets smaller so that's pretty much essentially how the plastic is really so you have different color plastic gauges for different measurements you have some that are bigger than this and some that are smaller than this so it just depends we're going to drop these Rod caps on tighten them down and make sure we're good and then if they are good we'll Lube them up and be done stretches [Music] running six went in nicely everything is perfect with them our bearing clearances are spot on so we're going to move to two and five and then we'll do three and four after thank you a rotating assembly is finished everything went together very nicely it feels really smooth which is good doesn't hang up on any spots and it looks beautiful our bees are a little funky especially this one because this is a higher compression so we did the math and we should have about 9.

3 to one compression on this thing the new Grady head is a fresh cylinder head casting and so it sticks up a little bit above the deck and the cylinder head will make up that gap which is really cool so overall really nice setup looks good we got some oil to clean off but we're gonna get to installing our oil pump now we have a beautiful Phillip pump by PRP and a titanium Hardware kit to go with it which is really nice this thing is going to be amazing so this is a spline Drve most of the RVs will have two flat kind of grooves on the second the rest of it's rounded so our crank has already been set up for spline drive that's one of the things they did the machine shop this is going to make this pump a lot more resilient and not prone to the issues that the the flat Drve pumps have which is good so we're gonna prime the pump get it on the engine and then we're going to start tackling our block brace which is next it's over there but let's get this thing thank you [Music] foreign [Music] so this is a block brace it's gonna add a lot of strength to the block itself and we're pushing mad power it doesn't come apart [Music] all right [Music] black brace is installed so this component is a huge structure Improvement on the rb26 Block we're using here or the rv25 block we're using here in this case because we have an rv25 block on rb26 block not only is this going to stiffen up and block itself this also allows us to drop a all-wheel drive oil pan on our four wheel drive oil pan Which is an rb26 pin the 25s didn't come with all-wheel drive or some of them didn't at least this one did it so it doesn't have any of the provisions for the all-wheel drive oil pan but this fixes that and it strengthens up the block which means we can put a lot more power through this thing without having to worry about it so we've got all of our Hardware is in on and torqued aside from these so these will actually go through the pen through the block race into the block but for now because we have a little bit of silicone to let it dry out I have some Hardware it's just kind of clamping it down to hold it in place so the next step is going to be installing the pump pickup so this is the pump pickup that comes with the kit so that's Red Zone there this is actually from a stock pump pickup and I've locked the hose end off the two Bend well that shut we're going to drill a hole in the middle and position that and weld it there now the important part about this is this needs to have a seven millimeter air gap between the top of this and the bottom of the oil pan so I'm going to cut this hole out we're going to tack that in place and we're going to go to measure it and make sure we have the clearance we need and then we'll install it foreign [Music] pickup about seven millimeters off the bottom of the pan and when we put the pan on I'm not going to be able to measure it so what I've got here is a glob of grease and this is actually a little bit taller than seven millimeters oh I just moved out let's see where we're at that's almost seven millimeters so this little thickness here is seven so what we're going to do is leave that there we're going to drop the pan on and then if it's seven millimeters it'll touch right there and then we'll be money and if it doesn't touch then we gotta move this whole assembly so I press this in but this can come up a little bit we'll press it up retry and then if it smashes this completely and it's just like flat and we have too much interference and that's not good and then we'll maybe cut some off of the pipe or whatever and then bring it down a little bit so let's get our pan Which is heavy [Music] bro that is so tall what is that that's way too tall that was way too okay so we gotta cut this we gotta we gotta we gotta figure out a different technique I I thought this pole this pipe was going to be like within the range where we need to be but it's not so we've missed by like a lot so I've measured the depth of the oil pan and measured the deck height of the block with this so the top of our pump pick up here should be like here so I'm gonna wipe these two off set it where it needs to be and that'll give us kind of our cut line and then we'll re-weld it foreign [Music] a little bit of a process but we got our oil pickup height done and correct this thing is seven millimeters off the top which is good so we had a little bit of a range so we could go from about five to about eight eight and a half I chose seven because I was just like a solid Target number to hit and we got there so we're good ready for oil pan now baby [Music] all right we've got all of our oil pan Hardware sorted we know where everything goes we know it's going to go on and now it's time to get our formula Place gasket on the oil pan drop this thing on get it bolted down we're gonna have to let it cure for about a day before we can put oil in it and reprim the system but it should be good we can keep moving foreign [Music] so while we're waiting for the pan to dry so I like to kind of take everything down and tighten them in kind of steps and take more time with it so it sets properly because while we're waiting for it I'm going to keep going and we're going to get our water pump on here which uses forming Place gasket as well we also have a beautiful Hardware kit from PRP these are titanium they're very nice so we're gonna get this thing packed down we're also going to be using their alternative bracket kit so this is actually for an LS alternator instead of an rv26 one because it's a little bit stronger that guy's going to go out there on top of the water pump so we're gonna get this thing glued down good [Music] we're going to start installing our crank trigger kit so this is a 32 tooth PRP Trigger kit that we'll be putting on Arby's from the factory actually don't have any orientation or any setup for crank trigger they only go off the cam so this is going to give us much better engine management you'll let us know what the crankshaft is doing just give a more precise on the tuning side which is really cool so let's get this thing on thank you [Music] we're just about ready to throw the cylinder head on but we need to change some things in the block first mainly of these oil restrictors so this is an over 25 block so they have two restrictors so the rb26 has the rear one block so we're going to put a zero restrictor in there and then we're going to put a 1. 1 restrictor here kind of uh again our old pressure where we need it to be so we're going to change these install these and then we'll drop for some of your headline so I'm going to take a punch and we're going to sync the old restrictors down [Music] all right so we're gonna put one headset in the front one headset at the back drop our gasket on and then drop the cylinder head on so these are half inch so these are oversized compared to a factory head stud this is going to make it a lot stronger which is really nice got our gasket on this is a covering gasket I think they're really cool this is actually not the first time we've used one on this channel we did one way back when we built Evans M3 but essentially I like these better than like a multi-layer steel gasket you're less prone to leaking because you have more of a traditional gasket material on the outside which seals really well and then on the inside you have these steel fire rings and these have little grooves and then they'll actually bite into the cylinder head and give a really strong seal so very strong performance gasket and yet it seals beautifully so we're ready for our cylinder head [Music] we got our cylinder head on the rb26 and I'm putting our head studs in now and aside from this thing being an absolute UD why don't you tell us a little bit about the cylinder head this is actually a really special cylinder head this is one of the first to come from a Grady performance here in Irvine California this is their new head package program that is available to the public they're also doing a turnkey engine program as well or a long block program that you can buy directly from greddy pre-built so literally shows up on a crate you plop it in your car Plumb it and it's good to go because we did have a block prepped by PRP we wanted to utilize the Grady head in conjunction with that so as you saw we've got an extremely domed IRP piston and this head was cut to accommodate that and get us to a nine point was 9. 3 1.

Related Videos

![+700HP SR20DET Engine Build - Full Start to Finish [4K]](https://img.youtube.com/vi/TvqgprMMn8g/mqdefault.jpg)

33:43

+700HP SR20DET Engine Build - Full Start t...

throtl

327,194 views

29:59

Assembling a 500HP Miata Engine From The B...

TheCarPassionChannel

1,471,083 views

![+1,000HP 2JZ-GTE Engine Build - Full Start to Finish [4K]](https://img.youtube.com/vi/C9lpWAlSvtw/mqdefault.jpg)

43:06

+1,000HP 2JZ-GTE Engine Build - Full Start...

throtl

2,875,265 views

1:18:57

OEM+ Rebuild of a 37-Year-Old V12 Engine -...

M539 Restorations

869,915 views

17:50

Ford 460 Engine Build On A Budget Part 1 -...

POWERNATION

3,282,490 views

23:44

RB26 vs 2JZ | and WHY the RB26 is MORE ICO...

driving 4 answers

296,888 views

42:31

440 Mopar V-8 Engine Build | Redline Update

Hagerty

1,268,384 views

17:38

The RB26 Engine-Build | ASMR | Part 1l Sub...

Subi Performance

159,683 views

24:11

Carbon Fiber Inside the Engine - How CF ro...

driving 4 answers

2,845,983 views

19:03

Fully Built Subaru STi Engine | ASMR

Devin Niemela

1,324,407 views

22:36

+400HP RB20DET Engine Build!

throtl

313,844 views

14:25

Toyota 2JZ Engine Build - Full Start to Fi...

PapadakisRacing

9,680,956 views

18:09

Seized-up Ford V8 Engine from Barn Find Pa...

Hagerty

3,927,386 views

40:07

Rebuilding an Abandoned 1.8t Audi TT ~ Buy...

HumbleMechanic

294,237 views

18:41

Mercedes AMG V8 ENGINE - PRODUCTION (Germa...

GommeBlog.it: Tecnica e Performance

9,248,932 views

18:36

RB26 FULL ENGINE BUILD || Episode 1: Tools...

Boost Factory

16,702 views

13:06

Why It’s Almost Impossible to Rev to 21,00...

Driver61

736,764 views

12:57

2020 Supra 1000 HP Engine Assembly - Start...

PapadakisRacing

3,607,431 views

47:27

Building a Honda K20 | Jay Teaches Novice ...

That Racing Channel

506,925 views

12:01

How Nissan Built The Greatest Inline-6 | E...

337 SPEED

444,680 views