Factorial vs fractional vs response surface designs | when to use what?

2.17k views1122 WordsCopy TextShare

Marcel Butschle

Expand your toolbox of experimental designs. Save time and money and become a better researcher!

🎓...

Video Transcript:

you never heard of fractional design did you know that it can save you a lot of time especially in the beginning of a project experimental design is the backbone of every research project but you might be thinking why do I need to bother with different experimental designs well I think of it like this the different experimental designs are like your basic toolbox sometimes it's just easier to use a screwdriver instead of a hammer same with different experimental designs sometimes it makes sense to use a full factorial design sometimes you want to use fractional designs or

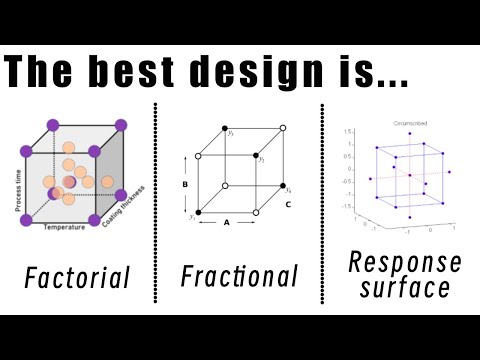

sometimes you want to use a response surface design this video will cover the basics of these three designs and give suggestions of when to use what let us assume that you plan an experiment with three variables you're testing how the coating hardness is influenced by baking temperature baking time and coating thickness based on your experience you come up with the range for these three variables that you want to test if you think of your experimental design space as a cube a two level full factorial design would position your individual experiments on the edges of the

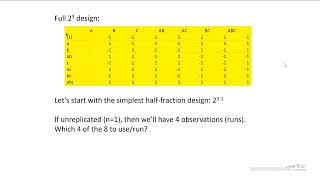

cube a total number of experiments is eight if you do not include any replicates which you should this number increases exponentially with every additional Factor if for example you're also deciding to add the coating type to your experiment you would do 16 experiments instead of eight and if you even add a fifth Factor you end up with 32 individual runs if the number of factors becomes too high for a full factorial design you can go for a fractional design meaning that you only have to do a fraction of the runs that you had to do

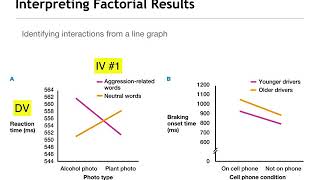

for a full factorial but of course there's a catch you're losing some information the great benefit of full factorial designs is that you're getting information about interactions between variables what is an interaction an interaction means that the effect that a factor on the result has depends on the level of the second effect whatever that means here's an easy example imagine you're trying to find out how the topping changes the taste of food you're testing ice cream and the German classic currywurst as you're topping you have chocolate sauce and ketchup and maybe you're already seeing where

I'm going with this it is very difficult to generalize the effect that the topping has on the food because it very much depends if you put the chocolate sauce on the ice cream or on the currywurst if you transfer this to our Coatings example it might be that the coating thickness does not influence the hardness when the baking time is at 30 minutes but because of solvent retention it significantly reduces the hardness when the baking time is at only 10 minutes and while with the full factorial design you get all the information about all the

interactions they might be hidden if you only do a fractional design but the beauty with fractional designs is is that you can always run the missing fraction to get all the information if you need it while fractional designs are there to get the results fast with a limited amount of time by sacrificing some depth of information response surface designs are the opposite you perform a response surface design when you really want to know the details about your system but why not use a full factorial design for that well with the two level full factorial design

you can only fit a linear model but a linear model doesn't contain the details that you're interested in so why not perform a three-level full factorial design trust me you don't want to do that a three level full factorial design would result in 27 individual runs with four factors you already have to do 81 experience that's why we have the response surface design if you remember the cube of our two level full factorial design it would look like this for a three level full factorial design how however for response surface design instead of adding all

these additional runs you're only adding additional experiments at the center of the cube and at the center of each one of the square faces you still get the additional complexity but only have to do 18 runs or 28 runs for three or four factors respectively now let me try to give you suggestions for how to use these three different designs and feel free to comment if you have different ideas or if you disagree generally I would suggest to start with the fractional design especially if you have a large number of factors and relatively few information

about the importance of these factors because you always can extend to a full factorial design if you need more information without having to repeat the experiments you already did however there might be some exceptions to this for example when sample preparation takes a relatively low time compared to testing what comes to mind is testing the corrosion properties of a coating you might be able to prepare a large number of samples within a week but the testing procedure can take several months or even years to finish and after you waited so long you really want to

get the most information out of your design I would perform a full factorial design after identifying all the relevant factors and excluding all the insignificant factors if you're smart and if you design your fractional experimental design the right way you might not even need to perform any additional experiments but can just analyze a subset of your fractional design as full factorial design let me know in the comments if you want me to cover that in one of my future videos last but not least when to use response surface designs well probably the obvious answer is

when you performed a two level full factorial design and you find that the information you gained isn't enough and you need more details but a very good application for response surface designs is also to find robust process parameters let's say the coating hardness increases as a function of process time until it reaches a plateau for a robust process I would actually set the process time somewhat away from the slope here because then even if we have slight variations in the time the result will not be influenced much finding robust process parameters is neither possible with

fractional designs nor with full factorial designs at least not with as few runs as in a response surface design [Music] foreign

Related Videos

14:02

Planning and analyzing a 2-level full fact...

Marcel Butschle

2,796 views

18:16

Response Surface Methodology

Paul Allen

33,218 views

13:29

DOE-5: Fractional Factorial Designs, Confo...

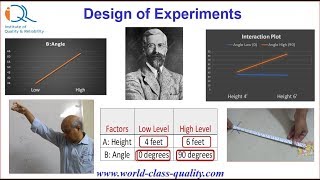

Institute of Quality and Reliability

50,007 views

15:56

Factorial Design; Example

PHARMA TRICKS FOR EXAMS

20,168 views

9:03

DOE using JMP® Software: Construction and ...

PegaAnalytics

61,493 views

20:21

Lecture71 (Data2Decision) Response Surface...

Chris Mack

68,752 views

11:31

Factorial Designs: Main Effects & Interact...

S. Wesley Beckwith

63,770 views

13:50

Fractional Factorial Design in Minitab

Institute of Quality and Reliability

21,819 views

29:27

Full Factorial Design of Experiments

Sarah Flashing

96,233 views

6:22

3.9 Quasi-experimental designs | Quantitat...

Research Methods and Statistics

151,437 views

11:13

Fractional Factorial Design, Part 1

LearnChemE

24,531 views

14:06

Factorial Designs Describing Main Effects...

Dr. Kristin Atchison

67,782 views

15:05

DOE-7: Analyse Factorial Design with Minit...

Institute of Quality and Reliability

26,781 views

17:16

How Physicists FINALLY Solved the Feynman ...

Dr Ben Miles

920,031 views

9:08

Response Surface Methodology (RSM) analysi...

Science Roast

67,784 views

10:15

Tutorial: Central Composite Designs with M...

Luc Dewulf To Be Deleted

23,271 views

33:14

Fractional factorial design

Biostatistics and Design of experiments

24,766 views

12:36

DOE-1: Introduction to Design of Experiments

Institute of Quality and Reliability

71,241 views

12:48

Response Surface Methodology Box Behnken D...

Engineering and Info

5,752 views

31:51

Design of Experiments (DOE) – The Basics!!

Green Belt Academy

3,666 views